304、316系列奧氏體不銹(xiu)鋼(gang)常用于制造與人們生活密切相關的不(bu)銹鋼餐廚具,如制造大型廚房設備、家電、刀具、餐具、洗碗機、豆漿機、微波爐、熱水器、烤爐、水槽、冰箱、水杯等產品。

304不銹鋼在廚房行業廣泛應用,其優異的成型性能使水槽的多樣化設計成為可能。與早期的陶瓷水槽相比,不銹鋼雙槽、一體排水槽等都極為便利,而且比塑料復合材料更耐熱和耐損傷,能夠經受住最有腐蝕性食物的腐蝕和多年的粗糙清洗,因而得到廣泛使用。它也補充了操作臺面的顏色或設計,因此不銹鋼現已成為商業和家庭炊具的主要材料。尤其是304型號的不銹鋼大量地替換了諸如瓷磚、鋁和塑料復合板等材料,因為它們抗熱、不易損壞,并能保持清潔,如圖B.1所示。

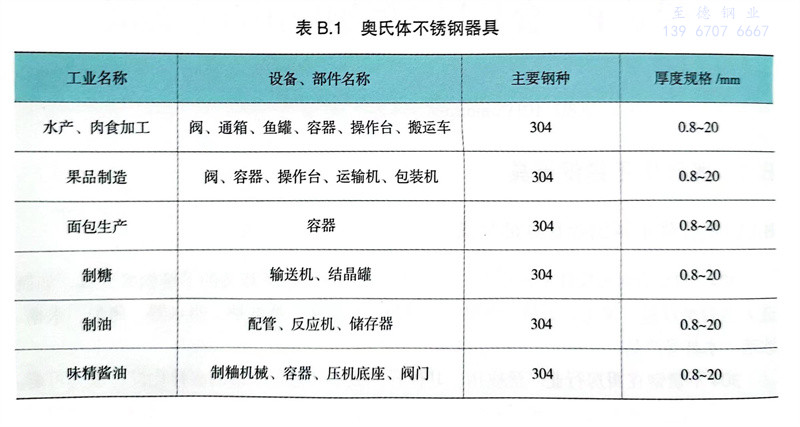

304不(bu)(bu)(bu)銹(xiu)鋼(gang)在(zai)食(shi)(shi)(shi)(shi)品(pin)(pin)行(xing)業(ye)使用(yong)(yong),雖然通(tong)常食(shi)(shi)(shi)(shi)品(pin)(pin)成(cheng)品(pin)(pin)酸(suan)堿(jian)度(du)(du)(du)適(shi)中,但在(zai)整個生(sheng)產(chan)過程(cheng)中,可(ke)能存在(zai)強酸(suan)強堿(jian)環境。部分(fen)食(shi)(shi)(shi)(shi)品(pin)(pin)成(cheng)品(pin)(pin)中,含較多的(de)食(shi)(shi)(shi)(shi)鹽(yan)(yan)成(cheng)分(fen),或在(zai)加工過程(cheng)中要接(jie)觸到(dao)食(shi)(shi)(shi)(shi)鹽(yan)(yan)溶(rong)液。為了除去果蔬上的(de)殘(can)留農藥,可(ke)能要用(yong)(yong)稀鹽(yan)(yan)酸(suan)浸泡。果蔬化(hua)學去皮(pi)法(fa)用(yong)(yong)氫氧(yang)(yang)化(hua)鈉或氫氧(yang)(yang)化(hua)鉀,且要用(yong)(yong)鹽(yan)(yan)酸(suan)中和。柑桔去囊(nang)農時(shi)(shi),用(yong)(yong)到(dao)燒堿(jian)、鹽(yan)(yan)酸(suan)、硫酸(suan)等(deng)溶(rong)液;鹽(yan)(yan)酸(suan)濃(nong)度(du)(du)(du)達10%,溫度(du)(du)(du)達80℃。硫酸(suan)濃(nong)度(du)(du)(du)用(yong)(yong)到(dao)15%,溫度(du)(du)(du)達80℃。水果凍前加二氧(yang)(yang)化(hua)硫等(deng)添加劑,以延(yan)緩氧(yang)(yang)化(hua)作用(yong)(yong)。果蔬抽空(kong)排氣時(shi)(shi)放入食(shi)(shi)(shi)(shi)鹽(yan)(yan)溶(rong)液。青豆用(yong)(yong)鹽(yan)(yan)水進行(xing)浮選(xuan)。罐頭食(shi)(shi)(shi)(shi)品(pin)(pin)中用(yong)(yong)食(shi)(shi)(shi)(shi)鹽(yan)(yan)作添加劑。醬及(ji)(ji)醬油(you)食(shi)(shi)(shi)(shi)品(pin)(pin)中含有大(da)量食(shi)(shi)(shi)(shi)鹽(yan)(yan)成(cheng)分(fen)。腌制食(shi)(shi)(shi)(shi)品(pin)(pin)時(shi)(shi)腌制劑有食(shi)(shi)(shi)(shi)鹽(yan)(yan)、硝(xiao)酸(suan)鈉、亞硝(xiao)酸(suan)鈉、磷酸(suan)鹽(yan)(yan)等(deng)。因此,根據不(bu)(bu)(bu)同品(pin)(pin)種(zhong)及(ji)(ji)不(bu)(bu)(bu)同生(sheng)產(chan)工藝,選(xuan)用(yong)(yong)合適(shi)的(de)不(bu)(bu)(bu)銹(xiu)鋼(gang)材料(liao)及(ji)(ji)加工方法(fa)是非常必要的(de),稍有疏忽,機(ji)械設備在(zai)使用(yong)(yong)過程(cheng)中就有銹(xiu)蝕的(de)危險。不(bu)(bu)(bu)銹(xiu)鋼(gang)在(zai)食(shi)(shi)(shi)(shi)品(pin)(pin)加工與餐廚具應用(yong)(yong)與對(dui)應設備選(xuan)擇(ze)如表B.1所示。