1. 技(ji)術條件

板材為304不銹鋼,板厚10mm;筒體直徑為2400mm,長為9896mm;工作壓力為0.25MPa;工作介質為發酵液蒸氣;工作溫度為145℃.

2. 焊接工(gong)藝規范

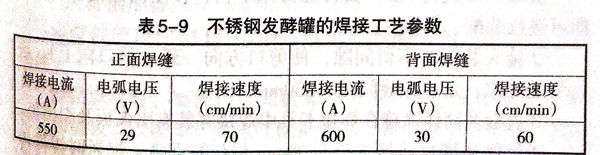

采用Ⅰ形坡(po)(po)口(kou),根(gen)部間隙為(wei)(wei)4mm,坡(po)(po)口(kou)及兩(liang)側50mm以內清理干凈,不(bu)得有油(you)污及雜(za)質;焊絲為(wei)(wei)H0Cr21Ni10,直徑(jing)為(wei)(wei)4mm;焊劑為(wei)(wei)HJ260,250℃烘(hong)干并保溫2h;電源為(wei)(wei)直流反接(jie);工藝參數見表5-9.

為防止475℃脆化及δ脆性相析出,焊接過程中,采用反面吹風及正面及時水冷的措施,快速冷卻焊縫。

焊后進(jin)(jin)行(xing)(xing)(xing)焊縫外(wai)觀檢驗,然后進(jin)(jin)行(xing)(xing)(xing)20%的X射線(xian)探(tan)傷(shang),且符合JB4730-1994《壓(ya)力容器無損檢測》Ⅱ級要求,同時對工藝(yi)進(jin)(jin)行(xing)(xing)(xing)檢查:進(jin)(jin)行(xing)(xing)(xing)X射線(xian)探(tan)傷(shang)和力學性能試(shi)驗,合格后進(jin)(jin)行(xing)(xing)(xing)整體(ti)水壓(ya)試(shi)驗,試(shi)驗壓(ya)力為0.31MPa.