二氧化碳液態低溫容器槽車是由外容器和內容器組成。內容器材質為06Cr18Ni11Ti不銹鋼,壁厚16mm。內容器外形尺寸:直徑1600mm,長為5786mm,容積為11m3。除進行外觀目視檢查外,還必須對焊縫進行100%的滲透檢測和100%的射線檢測。內容器還要進行2.88MPa干燥無油壓縮空氣試驗和氦質譜真空檢漏,漏氣率不大于2×10-5Pa·L/s。

焊(han)(han)接工藝:所有縱焊(han)(han)縫和(he)環(huan)焊(han)(han)縫(除一端(duan)頭與筒(tong)體環(huan)焊(han)(han)縫外)均采用埋弧焊(han)(han),焊(han)(han)機型號(hao)為MZ-1000型,采用直流反極性電源。焊(han)(han)絲牌(pai)號(hao)H08Cr19Ni10Ti,直徑(jing)為4mm,焊(han)(han)劑為HJ260。

1. 縱(zong)縫(feng)埋(mai)弧焊

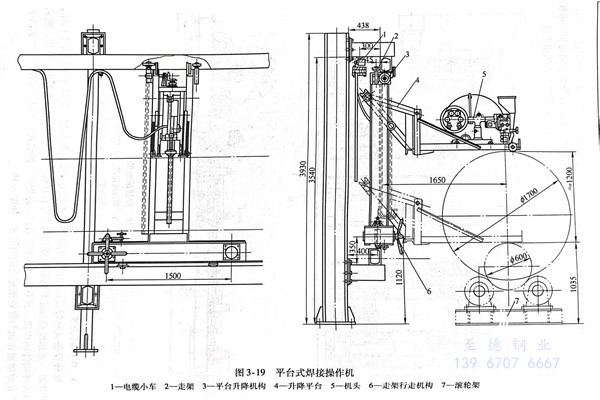

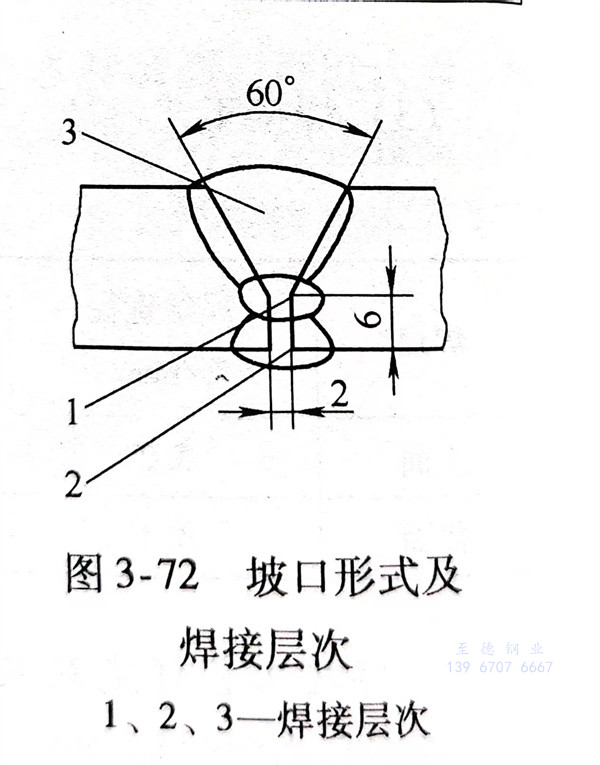

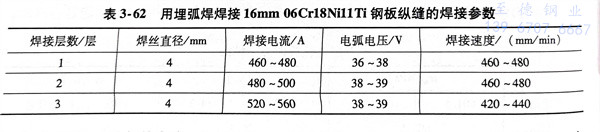

鋼板放在(zai)(zai)刨邊(bian)機上按圖(tu)3-72進(jin)(jin)行坡口加工,待焊(han)鋼板放在(zai)(zai)門(men)式焊(han)接夾具(圖(tu)3-19)上進(jin)(jin)行裝配,待焊(han)處清(qing)除油污后(hou)進(jin)(jin)行焊(han)接,焊(han)接參(can)數見表(biao)3-62,焊(han)好第(di)1、2層(ceng)焊(han)縫(feng)(feng)后(hou)要進(jin)(jin)行清(qing)根(gen),先用碳弧氣刨,然后(hou)用風(feng)動砂輪清(qing)理打(da)磨(mo)出金屬光澤,并保證清(qing)根(gen)后(hou)凹槽(cao)尺寸均勻一致,然后(hou)焊(han)接第(di)3層(ceng)焊(han)縫(feng)(feng)。

2. 環縫埋弧焊(han)

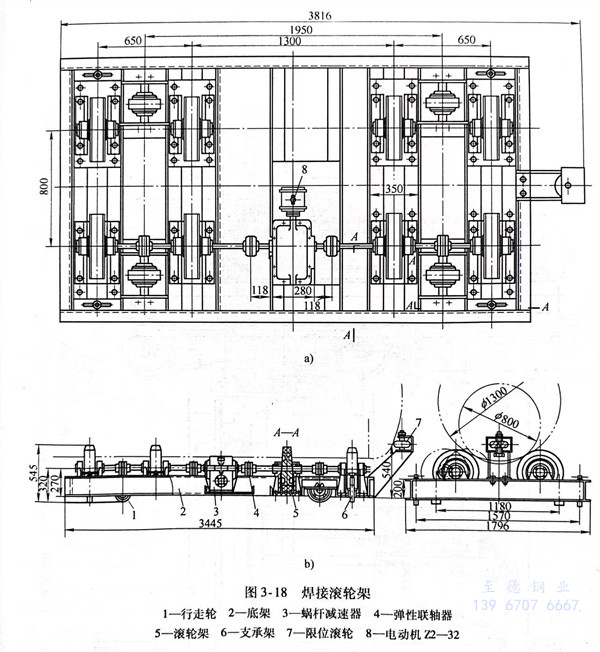

環縫(feng)(feng)埋弧(hu)焊(han)(han)(han)(han)(han)接包括筒(tong)節與筒(tong)節和筒(tong)節與一端頭的環縫(feng)(feng)焊(han)(han)(han)(han)(han)接。將焊(han)(han)(han)(han)(han)好的筒(tong)節、封(feng)頭放在(zai)焊(han)(han)(han)(han)(han)接滾(gun)輪架(見圖3-18)上進行裝配,用焊(han)(han)(han)(han)(han)條電弧(hu)焊(han)(han)(han)(han)(han)進行定位焊(han)(han)(han)(han)(han),在(zai)平臺(tai)式焊(han)(han)(han)(han)(han)接操作機上(如圖3-19)進行環縫(feng)(feng)焊(han)(han)(han)(han)(han)接,先焊(han)(han)(han)(han)(han)內焊(han)(han)(han)(han)(han)縫(feng)(feng)(第1、2層)然后(hou)按縱縫(feng)(feng)工藝進行清根再焊(han)(han)(han)(han)(han)第3層焊(han)(han)(han)(han)(han)縫(feng)(feng),焊(han)(han)(han)(han)(han)接參數可(ke)參表3-62。

上(shang)述(shu)縱(zong)、環縫焊接完畢(bi),先進(jin)行目視(shi)檢(jian)查,然后進(jin)行100%滲透檢(jian)測,排(pai)除焊縫表(biao)面缺陷后,再進(jin)行100%射線檢(jian)測,焊縫內部(bu)質量應達到設(she)計圖樣要(yao)求后才(cai)能進(jin)行下(xia)面工序(xu)。

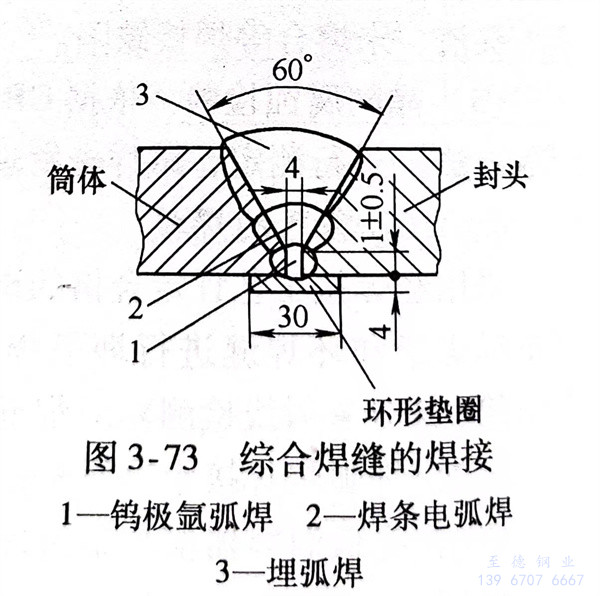

3. 另一(yi)封頭(tou)與筒(tong)體焊接

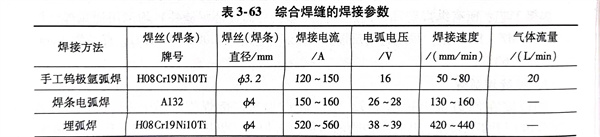

內容(rong)器(qi)是一個(ge)密封(feng)容(rong)器(qi)(除(chu)輸(shu)入、輸(shu)出液管路外(wai)),沒有人孔(kong)裝(zhuang)置(zhi),焊(han)(han)(han)(han)(han)(han)(han)接設備和人員無法(fa)進(jin)(jin)入容(rong)器(qi)內操作(zuo)。采用的(de)(de)(de)焊(han)(han)(han)(han)(han)(han)(han)接工(gong)藝(yi)如圖3-73所(suo)示。內環(huan)縫(feng)增(zeng)加了一個(ge)環(huan)形(xing)墊(dian)圈(quan),材質(zhi)與(yu)內容(rong)器(qi)材質(zhi)相同,墊(dian)圈(quan)厚(hou)度(du)為4mm,寬度(du)為30mm。先用鎢極氬弧(hu)(hu)焊(han)(han)(han)(han)(han)(han)(han)進(jin)(jin)行(xing)(xing)打底焊(han)(han)(han)(han)(han)(han)(han),保證焊(han)(han)(han)(han)(han)(han)(han)透(tou)實(shi)現單面焊(han)(han)(han)(han)(han)(han)(han)雙面成形(xing),通過(guo)100%射線檢(jian)測(ce)判片合格后(hou),進(jin)(jin)行(xing)(xing)第2層(ceng)焊(han)(han)(han)(han)(han)(han)(han)條電弧(hu)(hu)焊(han)(han)(han)(han)(han)(han)(han),其目的(de)(de)(de)是提高(gao)焊(han)(han)(han)(han)(han)(han)(han)縫(feng)厚(hou)度(du),防止埋弧(hu)(hu)焊(han)(han)(han)(han)(han)(han)(han)時由于(yu)熔深過(guo)大而將(jiang)打底焊(han)(han)(han)(han)(han)(han)(han)焊(han)(han)(han)(han)(han)(han)(han)縫(feng)焊(han)(han)(han)(han)(han)(han)(han)穿。第3層(ceng)環(huan)形(xing)焊(han)(han)(han)(han)(han)(han)(han)縫(feng)用埋弧(hu)(hu)焊(han)(han)(han)(han)(han)(han)(han)完成。各層(ceng)焊(han)(han)(han)(han)(han)(han)(han)縫(feng)的(de)(de)(de)焊(han)(han)(han)(han)(han)(han)(han)接參數見(jian)表3-63。焊(han)(han)(han)(han)(han)(han)(han)后(hou)將(jiang)環(huan)焊(han)(han)(han)(han)(han)(han)(han)縫(feng)進(jin)(jin)行(xing)(xing)滲透(tou)檢(jian)測(ce)和射線檢(jian)測(ce)合格后(hou)再進(jin)(jin)行(xing)(xing)無油(you)干燥氣(qi)壓試(shi)驗和氮質(zhi)譜(pu)真(zhen)空檢(jian)漏。全部滿足圖樣技(ji)術(shu)性能要求后(hou)才能與(yu)外(wai)容(rong)器(qi)進(jin)(jin)行(xing)(xing)組裝(zhuang)。