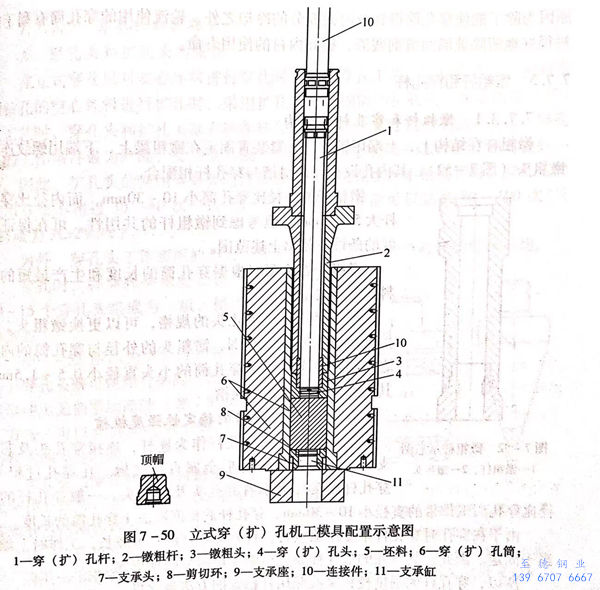

立式不銹鋼管穿(擴)孔機的工模具配置取決于穿(擴)孔機的結構形式,穿(擴)孔過程的工藝要求,以及穿(擴)孔時坯料金屬變形時的流動特點。和臥式擠壓機的工模具配置一樣,穿(擴)孔機工模具配置的基本形式由穿(擴)孔筒(內襯和外套)、鐓粗桿、鐓粗頭、穿(擴)孔頭、支承桿、支承頭、剪切環以及連接件組成,如圖7-50所示。

一、穿(chuan)(擴)孔筒(tong)

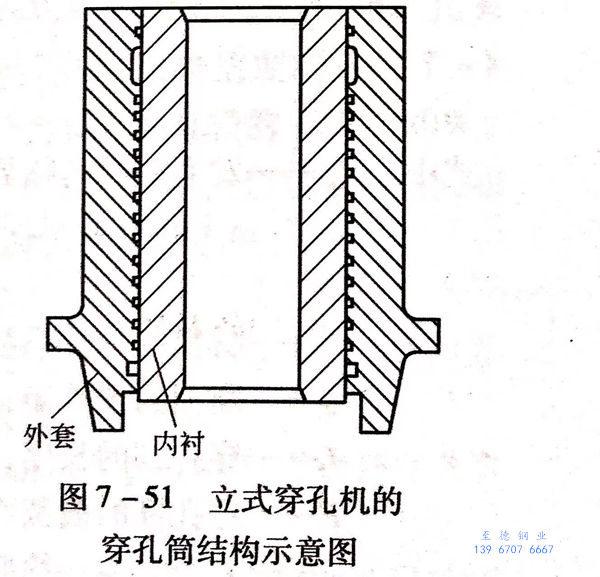

當不(bu)銹鋼管坯料(liao)進行穿和擴孔時,穿孔筒內襯承受相當小的單位壓力(不大于590MPa).因為從坯料穿孔或擴孔方向的垂直滑移摩擦力實際上是沒有的。但是,因與加熱到高溫的坯料直接接觸時間長達30s,引起穿孔筒內襯劇烈受熱。長久使用后的穿孔筒內襯以焊瘤的形式引起變形而損壞,或使穿孔坯料取出產生困難。因此,當其在高速工作時應采取強制冷卻的方法來降低穿孔筒內襯的溫度。通常在穿孔筒外套的內壁車有螺旋冷卻水槽(圖7-51)來冷卻內襯。

一般穿孔(kong)筒的(de)內襯與外套之間(jian)以(yi)1.0%~1.5%的(de)錐度相配合,而內襯的(de)內孔(kong)也制成約有1%~3%的(de)錐度,這樣使取(qu)出坯料時(shi)能比較順利地(di)頂出。

另外,穿孔筒內襯(chen)的內表面光潔度(du)要(yao)求比(bi)較高,熱處理(li)(li)后要(yao)進(jin)行(xing)磨削。其熱處理(li)(li)后的硬(ying)度(du)約為HRC42~45,以提高其耐磨性(xing)。

穿孔筒的(de)內襯采用和擠壓筒內襯相同的(de)材料(liao)制造,如(ru)5CrW2Si或Ni11.一般穿孔筒內襯的(de)使用壽(shou)命大約(yue)為(wei)1000~3000次(ci)。

從(cong)穿孔(kong)(kong)筒(tong)內襯的(de)工(gong)作條件(jian)來(lai)考量,采用具有雙(shuang)穿孔(kong)(kong)筒(tong)旋轉輪換工(gong)作結構(gou)的(de)穿孔(kong)(kong)機最為合(he)適。

原因為除了能使(shi)穿(chuan)孔(kong)筒(tong)得到及時而充(chong)分的(de)冷(leng)卻之外(wai),輪流使(shi)用(yong)的(de)穿(chuan)孔(kong)筒(tong)有利于內(nei)襯(chen)很好地清除玻(bo)璃潤滑劑(ji)殘(can)渣,提高(gao)內(nei)襯(chen)的(de)使(shi)用(yong)壽命。

二、鐓粗桿和穿孔(kong)桿

1. 鐓粗(cu)桿(gan)和穿(chuan)孔(kong)桿(gan)的結構(gou)

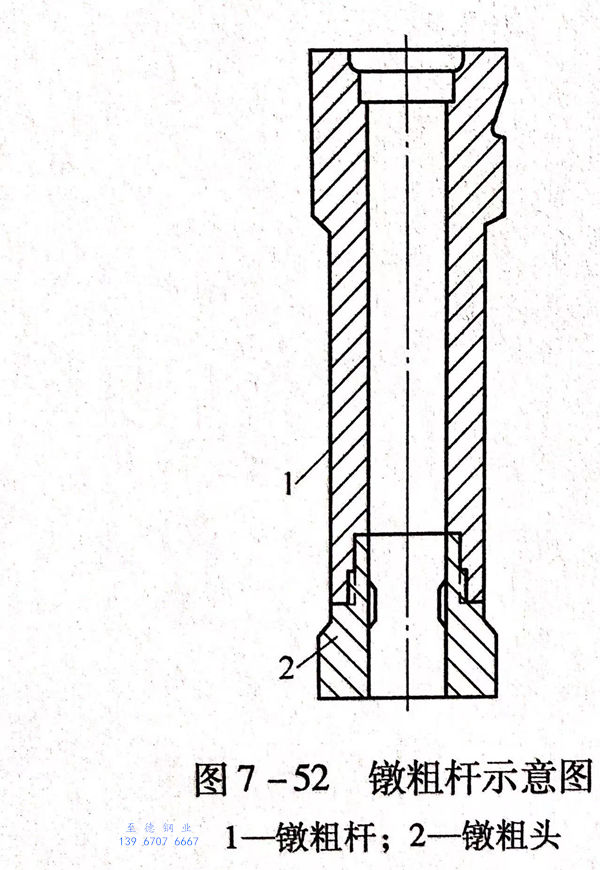

鐓粗桿在(zai)結構上(shang),上(shang)端用銷子或夾緊裝置固定在(zai)鐓粗梁上(shang),下端用螺紋連(lian)接鐓粗頭(tou)(圖7-52),其內孔設有導向滑槽與穿孔桿相(xiang)配合。

鐓粗桿(gan)的(de)外徑(jing)(jing)比穿孔筒小10~30mm,而(er)內徑(jing)(jing)比穿孔桿(gan)大5~25mm.但考慮到鐓粗桿(gan)的(de)共用性,可在保證強度的(de)條(tiao)件下超(chao)出(chu)上(shang)述范圍(wei)。

鐓(dui)粗桿的(de)長度應根據穿孔筒(tong)的(de)長度和生產最短的(de)坯料長度來決定。

根據穿(chuan)孔(kong)桿(gan)和穿(chuan)孔(kong)頭(tou)(tou)的(de)規格,可以(yi)更換鐓(dui)(dui)粗頭(tou)(tou),以(yi)擴大鐓(dui)(dui)粗桿(gan)的(de)使用范(fan)圍(wei),鐓(dui)(dui)粗頭(tou)(tou)的(de)外徑與穿(chuan)孔(kong)筒(tong)的(de)內(nei)徑之(zhi)間間隙要(yao)小,約比(bi)穿(chuan)孔(kong)筒(tong)的(de)小頭(tou)(tou)直徑小0.5~1.5mm,其內(nei)孔(kong)帶有花鍵式導(dao)向(xiang)槽。

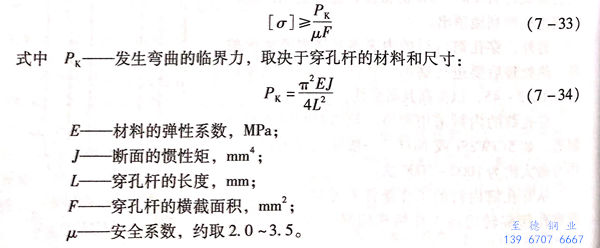

2. 穿孔桿的穩定(ding)性強度校核

立式(shi)穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)機的(de)穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)桿(gan)作為連(lian)桿(gan),連(lian)接(jie)(jie)(jie)(jie)穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)頭(tou)及(ji)芯(xin)棒支承,穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)并不和變形屬直接(jie)(jie)(jie)(jie)接(jie)(jie)(jie)(jie)觸。在穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)過程中,穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)桿(gan)連(lian)接(jie)(jie)(jie)(jie)并支承著穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)頭(tou)及(ji)擴孔(kong)(kong)(kong)(kong)頭(tou)。一般穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)桿(gan)的(de)直徑比(bi)穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)頭(tou)工作帶的(de)直徑小10~30mm.穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)桿(gan)的(de)長度取決于(yu)穿(chuan)(chuan)孔(kong)(kong)(kong)(kong)筒的(de)長度。

由(you)于在不(bu)銹鋼(gang)管(guan)穿孔時穿孔桿承受壓(ya)縮(suo)應力,且因(yin)穿孔桿的長度(du)較長,工(gong)作時上端相(xiang)當于固(gu)定。因(yin)此,其彎曲的危險性(xing)要比壓(ya)縮(suo)變形的危險性(xing)更大(da)。

所以,穿孔桿(gan)(gan)的(de)(de)強(qiang)度校核是按(an)照(zhao)壓桿(gan)(gan)穩定的(de)(de)方法來計算。

穿孔桿上(shang)所承受的應力(li)為:

3. 穿孔頭和擴孔頭

a. 穿孔(kong)頭和擴(kuo)孔(kong)頭的結構

在(zai)(zai)立式穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)機對實心(xin)坯料(liao)進(jin)行穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)時,采用(yong)(yong)穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)工(gong)(gong)藝(yi),需用(yong)(yong)穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou);而對帶預鉆孔(kong)(kong)(kong)(kong)(kong)的(de)(de)(de)空(kong)心(xin)坯料(liao)進(jin)行擴(kuo)孔(kong)(kong)(kong)(kong)(kong)時,采用(yong)(yong)擴(kuo)孔(kong)(kong)(kong)(kong)(kong)工(gong)(gong)藝(yi),則需用(yong)(yong)擴(kuo)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou)。在(zai)(zai)采用(yong)(yong)穿(chuan)(chuan)(chuan)(chuan)(chuan)(擴(kuo))孔(kong)(kong)(kong)(kong)(kong)工(gong)(gong)藝(yi)時,穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou)和擴(kuo)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou)都安裝在(zai)(zai)穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)桿上(shang)。對于(yu)穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)機的(de)(de)(de)工(gong)(gong)模具而言,穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou)的(de)(de)(de)工(gong)(gong)作條件最為(wei)嚴酷,受到最為(wei)強烈的(de)(de)(de)磨損(sun);而擴(kuo)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou)的(de)(de)(de)工(gong)(gong)作條件相對會好(hao)一(yi)些。因此(ci),擴(kuo)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou)的(de)(de)(de)使(shi)用(yong)(yong)壽(shou)命(ming)要比穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou)長。一(yi)般在(zai)(zai)生產不銹鋼(gang)管時,穿(chuan)(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou)的(de)(de)(de)使(shi)用(yong)(yong)壽(shou)命(ming)不超過(guo)30~40次/只,而擴(kuo)孔(kong)(kong)(kong)(kong)(kong)頭(tou)(tou)(tou)(tou)的(de)(de)(de)使(shi)用(yong)(yong)壽(shou)命(ming)可以達到80~100次/只(材質為(wei)3Cr2W8V).

另外,穿孔(kong)(kong)(kong)頭工(gong)作(zuo)表面的不均(jun)勻磨損,將引起(qi)穿孔(kong)(kong)(kong)后空心坯(pi)的壁厚不均(jun)。穿孔(kong)(kong)(kong)時(shi),將穿孔(kong)(kong)(kong)頭輪流安裝在穿孔(kong)(kong)(kong)桿(gan)上,由10~15穿孔(kong)(kong)(kong)頭組(zu)成(cheng)為一(yi)組(zu),循環輪流使用的效果最好。

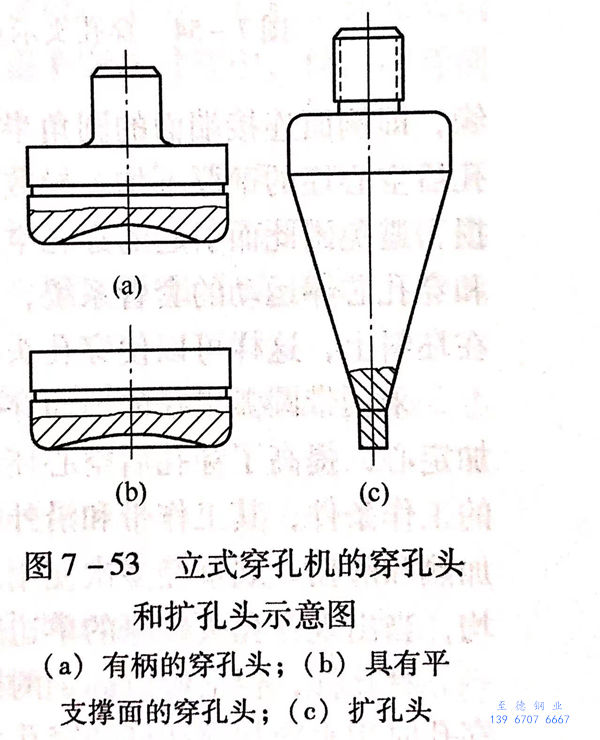

圖(tu)7-53所示為立式穿(chuan)(chuan)孔機(ji)的(de)穿(chuan)(chuan)孔頭(tou)和擴孔頭(tou)。穿(chuan)(chuan)孔頭(tou)既可(ke)使用有柄的(de)(圖(tu)7-53(a)),也可(ke)以使用無柄平端(duan)面的(de)(圖(tu)7-53(b)).這種固(gu)定方(fang)法,可(ke)以允許穿(chuan)(chuan)孔頭(tou)冷卻(que),檢查或更換,不占穿(chuan)(chuan)孔的(de)周期時間。

穿孔頭(tou)與(yu)穿孔坯料的接觸端面(mian)被做成帶有圓(yuan)弧半徑的凹(ao)面(mian),是為了保(bao)證在(zai)整個穿孔周期中(zhong),玻璃滑劑能夠均勻地進入變形區。

b. 穿孔(kong)(kong)頭(tou)和(he)擴孔(kong)(kong)頭(tou)的設計

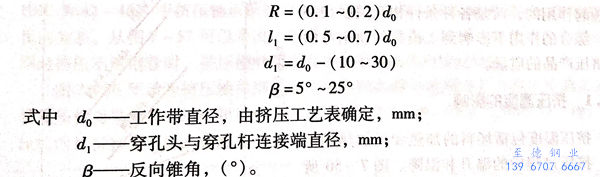

穿(chuan)孔(kong)頭(tou)(tou)(tou)(tou)(tou)和擴(kuo)孔(kong)頭(tou)(tou)(tou)(tou)(tou)的(de)(de)(de)設計數據來自于多年的(de)(de)(de)實際技(ji)術工作經(jing)驗數據。穿(chuan)孔(kong)頭(tou)(tou)(tou)(tou)(tou)(圖7-54)和擴(kuo)孔(kong)頭(tou)(tou)(tou)(tou)(tou)(圖7-55)定(ding)徑帶的(de)(de)(de)直徑,要根據產品(pin)的(de)(de)(de)規格而定(ding)。由于穿(chuan)孔(kong)頭(tou)(tou)(tou)(tou)(tou)和擴(kuo)孔(kong)頭(tou)(tou)(tou)(tou)(tou)在穿(chuan)(擴(kuo))孔(kong)過(guo)程中(zhong)直接(jie)(jie)與變形金屬接(jie)(jie)觸,因此,其表(biao)面光潔(jie)度應達到7~8級,且倒(dao)角要圓滑。穿(chuan)孔(kong)頭(tou)(tou)(tou)(tou)(tou)下(xia)端的(de)(de)(de)倒(dao)角半徑R應約為(wei)穿(chuan)孔(kong)頭(tou)(tou)(tou)(tou)(tou)直徑的(de)(de)(de)10%~20%。

穿(chuan)孔(kong)(kong)(kong)頭上端過渡(du)段(duan)的(de)角度不宜過大,以防(fang)止穿(chuan)孔(kong)(kong)(kong)頭回(hui)程(cheng)時刮傷空心坯的(de)內表(biao)面(mian),其角度一般為5°~25°.穿(chuan)孔(kong)(kong)(kong)筒和穿(chuan)孔(kong)(kong)(kong)頭較(jiao)小時,采用較(jiao)小值。

擴(kuo)孔頭(tou)的下錐頭(tou)直(zhi)(zhi)徑應等于坯料預鉆孔的直(zhi)(zhi)徑。

擴孔(kong)(kong)頭的成形錐角一般為30°~60°,太(tai)大(da)時擴孔(kong)(kong)坯的內壁(bi)容(rong)易(yi)刮傷,且擴孔(kong)(kong)開(kai)始時導向不好。其過(guo)渡段要平滑,以便使(shi)金屬流(liu)動(dong)均(jun)勻(yun)。

一般(ban)穿孔(kong)頭的直徑要比穿孔(kong)桿的直徑大10~30mm,但是(shi)有時考慮到穿孔(kong)桿的共用性,而(er)擴(kuo)大這(zhe)一數(shu)值(zhi)的范圍。

在穿(chuan)(chuan)(chuan)(chuan)孔過程中,穿(chuan)(chuan)(chuan)(chuan)孔頭(tou)嚴酷的(de)(de)工作(zuo)條(tiao)件,往往會(hui)使(shi)其(qi)工作(zuo)帶(dai)和沿外徑的(de)(de)棱緣(yuan),即(ji)側(ce)面(mian)連接端(duan)面(mian)的(de)(de)圓角半徑處,承受(shou)最大(da)的(de)(de)加(jia)熱和磨損。棱緣(yuan)的(de)(de)磨損引起穿(chuan)(chuan)(chuan)(chuan)孔后空(kong)心(xin)坯(pi)(pi)的(de)(de)壁厚不(bu)均,導(dao)致擠壓鋼管的(de)(de)壁厚不(bu)均。為(wei)了消(xiao)除穿(chuan)(chuan)(chuan)(chuan)孔頭(tou)的(de)(de)不(bu)均勻磨損,避免因此而引起的(de)(de)穿(chuan)(chuan)(chuan)(chuan)孔空(kong)心(xin)坯(pi)(pi)的(de)(de)壁厚不(bu)均,在現代的(de)(de)穿(chuan)(chuan)(chuan)(chuan)孔機上采用了穿(chuan)(chuan)(chuan)(chuan)孔桿(gan)和穿(chuan)(chuan)(chuan)(chuan)孔芯棒運動(dong)的(de)(de)套管系(xi)統,即(ji)在坯(pi)(pi)料經鐓粗(cu)后穿(chuan)(chuan)(chuan)(chuan)孔桿(gan)不(bu)立即(ji)返回,而是(shi)繼(ji)續壓在坯(pi)(pi)料上,這(zhe)樣可以使(shi)穿(chuan)(chuan)(chuan)(chuan)孔頭(tou)精(jing)確地對準坯(pi)(pi)料的(de)(de)中心(xin),并(bing)且(qie)減小(xiao)了其(qi)自(zi)由(you)長度。

采用帶圓弧半徑(jing)的(de)(de)(de)凹面穿(chuan)孔(kong)(kong)頭(tou)穿(chuan)孔(kong)(kong),實現(xian)了穿(chuan)孔(kong)(kong)桿和(he)穿(chuan)孔(kong)(kong)頭(tou)對穿(chuan)孔(kong)(kong)坯料的(de)(de)(de)附加定心,提高了穿(chuan)孔(kong)(kong)后(hou)空心坯的(de)(de)(de)壁(bi)厚(hou)均(jun)勻(yun)度。在穿(chuan)孔(kong)(kong)過程中,穿(chuan)孔(kong)(kong)頭(tou)處于最(zui)嚴酷的(de)(de)(de)工(gong)作(zuo)條件(jian),其(qi)(qi)工(gong)作(zuo)帶和(he)沿外徑(jing)的(de)(de)(de)棱(leng)(leng)緣,即側面和(he)端面的(de)(de)(de)圓角半徑(jing),承受最(zui)大(da)的(de)(de)(de)加熱和(he)磨損(sun)。觀察經多次使(shi)用后(hou)的(de)(de)(de)穿(chuan)孔(kong)(kong)頭(tou),其(qi)(qi)棱(leng)(leng)緣的(de)(de)(de)磨損(sun)引起穿(chuan)孔(kong)(kong)空心坯壁(bi)厚(hou)不(bu)均(jun),當出現(xian)穿(chuan)孔(kong)(kong)頭(tou)棱(leng)(leng)緣的(de)(de)(de)單邊磨損(sun)時,危險性更大(da)。

穿孔(kong)(kong)桿,包(bao)括螺紋固定(ding)的(de)穿孔(kong)(kong)頭在(zai)內,具有(you)通過沿軸線鉆孔(kong)(kong)的(de)冷(leng)卻水孔(kong)(kong)槽(cao)。穿孔(kong)(kong)時用水冷(leng)卻穿孔(kong)(kong)桿和(he)穿孔(kong)(kong)頭。

采用(yong)組合(he)式的穿孔(kong)(kong)工模具(ju),允許用(yong)低合(he)金鋼(gang)制(zhi)作不受熱的零件(jian),如(ru)采用(yong)5CrNiW、50CrVA鋼(gang)制(zhi)造(zao)(zao)固定穿孔(kong)(kong)桿(gan)的夾(jia)具(ju),用(yong)5CrNiW、5CrNiMo鋼(gang)制(zhi)造(zao)(zao)穿孔(kong)(kong)桿(gan),用(yong)高合(he)金鋼(gang)和耐(nai)熱合(he)金鋼(gang)制(zhi)造(zao)(zao)穿孔(kong)(kong)頭。

擴孔(kong)過程(cheng)中,擴孔(kong)頭(tou)(tou)的(de)錐形表面(mian)受(shou)到最劇烈的(de)磨損,并逐漸(jian)形成(cheng)劃道和凹陷。擴孔(kong)頭(tou)(tou)的(de)工作負(fu)荷較(jiao)穿(chuan)孔(kong)頭(tou)(tou)要輕許多,因此其使用壽命比(bi)穿(chuan)孔(kong)頭(tou)(tou)高得(de)多,一般可達(da)到80~100次。

擴孔(kong)(kong)頭(tou)的(de)(de)長(chang)度取(qu)決于穿(chuan)孔(kong)(kong)機的(de)(de)結構形式(shi),并且首先取(qu)決于穿(chuan)孔(kong)(kong)桿和穿(chuan)孔(kong)(kong)筒(tong)上平(ping)(ping)面之間的(de)(de)距離。如果其間隙大,為了(le)減小(xiao)成形角度,擴孔(kong)(kong)頭(tou)可以(yi)(yi)做得(de)比較長(chang)。擴孔(kong)(kong)頭(tou)成形角的(de)(de)平(ping)(ping)均值一(yi)般等于15°~20°,而在(zai)最(zui)大的(de)(de)擴孔(kong)(kong)程度時,可以(yi)(yi)達到(dao)30°~32°.

穿孔(kong)(kong)頭和擴孔(kong)(kong)頭必須(xu)具有(you)良好的綜合力(li)學(xue)性(xing)能,工作(zuo)表面光潔圓滑(hua),與(yu)穿孔(kong)(kong)桿連接可靠,更(geng)換方便(bian)。

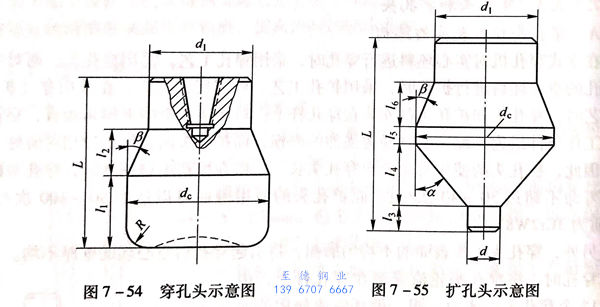

穿孔頭的形狀由端面圓角半徑R,工作帶l1和倒錐l2組成(圖7-54).各部分的尺寸,按以下經驗公式確定:

采用(yong)倒錐的(de)目的(de)是為(wei)(wei)了(le)防止穿(chuan)孔頭回程時刮(gua)切(qie)金屬(shu)或帶出空心坯。穿(chuan)孔頭端面(mian)加工成凹(ao)面(mian)的(de)目的(de),是為(wei)(wei)了(le)儲存潤滑劑(ji),以使在整個穿(chuan)孔過程中,保持潤滑劑(ji)的(de)連(lian)續供應。

擴孔頭由鼻尖l3、擴孔錐l4、工作帶l5和反向錐l6組成(圖7-55).鼻尖的作用是導向和定心,其直徑等于坯料鉆孔直徑,長度l3約為10~20mm,擴孔錐角α一般取15°~20°,當擴徑量大時,可達30°~32°,工作帶直徑dc由擠壓工藝表得到,其長度l5一般為6~10mm。

由(you)于(yu)擴孔錐至工作(zuo)帶處的磨損最為嚴(yan)重,故該處采(cai)用圓滑過渡,其他尺寸同上。

c. 剪切環組件(jian)

剪(jian)(jian)切(qie)環組件(jian)包括下支承桿、支承頭、剪(jian)(jian)切(qie)環和連接件(jian)等零部件(jian)。

支(zhi)承頭和剪切環(huan)的作(zuo)用(yong)是在穿(chuan)(chuan)孔(kong)過程中封閉穿(chuan)(chuan)孔(kong)筒(tong)內(nei)襯(chen)的下端面,以減(jian)小穿(chuan)(chuan)孔(kong)余(yu)料的高(gao)度(du),為空(kong)(kong)心坯(pi)下端面定(ding)形;在穿(chuan)(chuan)孔(kong)結束時,剪切環(huan)還要剪斷穿(chuan)(chuan)孔(kong)余(yu)料;支(zhi)承桿最后將穿(chuan)(chuan)孔(kong)空(kong)(kong)心坯(pi)從穿(chuan)(chuan)孔(kong)筒(tong)內(nei)襯(chen)中推出。

在整(zheng)個穿孔(kong)過(guo)(guo)程中,支承頭和剪切(qie)環(huan)的(de)上端面和加熱到(dao)(dao)高溫的(de)坯料相接(jie)觸,使(shi)其表面層金(jin)屬(shu)被加熱到(dao)(dao)650~700℃.使(shi)用過(guo)(guo)程中剪切(qie)環(huan)的(de)主要破(po)壞形(xing)式(shi)是端面棱緣翹曲和焊瘤(liu)(圖2-27).

剪(jian)切(qie)環與(yu)穿(chuan)孔(kong)頭或擴孔(kong)頭之間的間隙(xi)(xi)不(bu)能過大(da),一般小于2mm.如果此(ci)間隙(xi)(xi)過大(da)或剪(jian)切(qie)環過度(du)磨損(sun),則會(hui)導致在剪(jian)切(qie)穿(chuan)孔(kong)或擴孔(kong)余料(liao)的過程中(zhong),坯(pi)料(liao)前端內孔(kong)處(chu)產生飛(fei)邊缺陷,并易引(yin)起擠(ji)壓筒和擠(ji)壓模(mo)的損(sun)壞。