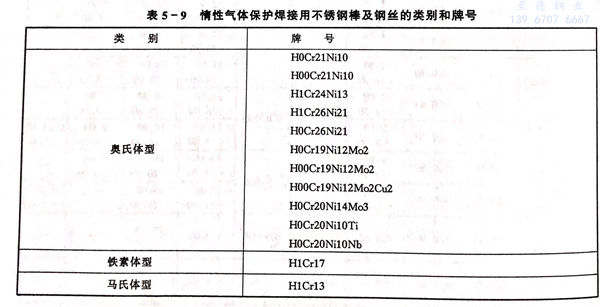

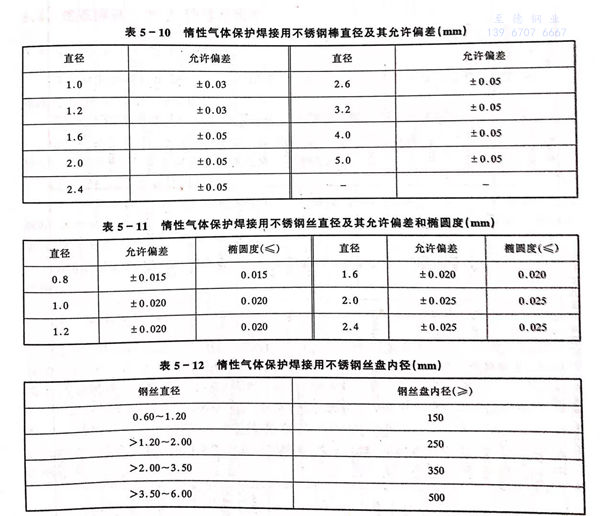

不銹鋼氣體保護焊接方法有如下形式:非熔化極氣體保護電弧焊,即鎢極惰性氣體保護焊(簡稱TIG焊);熔化極氣體保護電弧焊,包括熔化極惰性氣體保護焊(簡稱MIG焊)和熔化極活性氣體保護焊(簡稱MAG焊)。冶金部頒標準YB/T5091-93規定了惰性氣體保護焊用不銹(xiu)鋼棒及鋼絲的類別和牌號,見表5-9;對鋼棒直徑、鋼絲直徑和鋼絲盤內徑也有一定要求,分別見表5-10、表5-11和表5-12.其中鋼絲直徑和鋼絲盤內徑是氣體保護熔化極焊接方法提出的特殊要求。鋼絲應規整,不得散亂或成“8”字形。鋼棒長度為1000mm,允許正偏差≤50mm。

不銹(xiu)鋼(gang)氣(qi)(qi)體(ti)保(bao)護焊(han)(han)(han)(han)(han)(han)接方(fang)法(fa)中(zhong),TIG焊(han)(han)(han)(han)(han)(han)是(shi)最為普遍的(de)(de)焊(han)(han)(han)(han)(han)(han)接方(fang)法(fa)之一。它是(shi)用(yong)(yong)鎢極作為電極,通過不加填(tian)(tian)充(chong)(chong)焊(han)(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)或加填(tian)(tian)充(chong)(chong)焊(han)(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si),在惰(duo)(duo)性氣(qi)(qi)體(ti)保(bao)護氣(qi)(qi)氛中(zhong)進行的(de)(de)焊(han)(han)(han)(han)(han)(han)接。所(suo)(suo)謂不加填(tian)(tian)充(chong)(chong)焊(han)(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)焊(han)(han)(han)(han)(han)(han)接,就(jiu)(jiu)是(shi)將被焊(han)(han)(han)(han)(han)(han)母材金(jin)屬直(zhi)接加熱熔(rong)(rong)化(hua)(hua),待熔(rong)(rong)池(chi)凝固(gu)后(hou)直(zhi)接形成(cheng)焊(han)(han)(han)(han)(han)(han)接接頭(tou)。它廣泛應用(yong)(yong)于薄板的(de)(de)焊(han)(han)(han)(han)(han)(han)接。加填(tian)(tian)充(chong)(chong)焊(han)(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)焊(han)(han)(han)(han)(han)(han)接時(shi)(shi),所(suo)(suo)選(xuan)用(yong)(yong)的(de)(de)焊(han)(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)可通過從母材金(jin)屬裁剪截取,也可選(xuan)用(yong)(yong)表5-9中(zhong)的(de)(de)專(zhuan)用(yong)(yong)焊(han)(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)和鋼(gang)棒。保(bao)護氣(qi)(qi)體(ti)選(xuan)用(yong)(yong)純氬,它是(shi)一種很好的(de)(de)惰(duo)(duo)性氣(qi)(qi)體(ti),焊(han)(han)(han)(han)(han)(han)接過程中(zhong)不會氧(yang)化(hua)(hua),所(suo)(suo)以(yi)焊(han)(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)熔(rong)(rong)化(hua)(hua)后(hou)化(hua)(hua)學(xue)成(cheng)分基本不變,即焊(han)(han)(han)(han)(han)(han)絲(si)(si)(si)(si)(si)的(de)(de)化(hua)(hua)學(xue)成(cheng)分就(jiu)(jiu)是(shi)焊(han)(han)(han)(han)(han)(han)縫金(jin)屬的(de)(de)化(hua)(hua)學(xue)成(cheng)分。TIG焊(han)(han)(han)(han)(han)(han)接時(shi)(shi)熱輸入(ru)小(xiao),焊(han)(han)(han)(han)(han)(han)接接頭(tou)強度和韌、塑性都優(you)良,很容(rong)易滿足各方(fang)面的(de)(de)性能要(yao)求。

MIG焊是焊接不銹鋼機械化程度較高的方法之一,適用于薄、中厚度不銹鋼板的焊接。為了改善電弧特性,在Ar氣中混入適量O2或CO2,即成為MAG焊接方法。焊接超低碳不銹鋼時不能采用95%Ar+5%CO2混合氣體,只可采用98%Ar+2%CO2混合氣體。這是因為CO2氣的滲入使焊縫增碳,不利于焊接接頭耐腐蝕性能。無論MIG焊,還是MAG焊,必須選用惰性氣體保護焊接用鋼絲。

我(wo)國(guo)(guo)與(yu)部(bu)分國(guo)(guo)家情性氣體(ti)保護(hu)焊用不(bu)銹鋼焊絲(si)對照表見(jian)附(fu)表2。