等離子弧切割是現在不銹鋼加工過程中最常用的一種切割方法。它利用高速、高溫和高能的等離子氣流來加熱和熔化被切割的材料,并借助內部的或者外部的高速氣流或水流將熔化材料排開直至等離子氣流穿透背面而形成割口。等離子弧切割方法又分為一般等離子弧切割、水再壓縮等離子弧切割、空氣等離子弧切割。

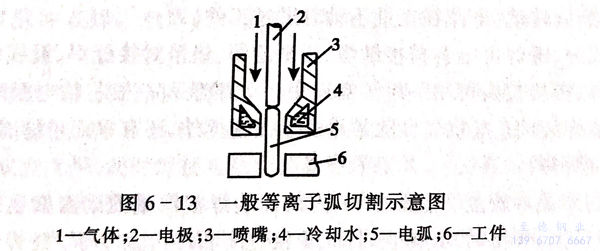

一般等離(li)(li)(li)子弧(hu)切(qie)(qie)割(ge)如圖6-13所示。切(qie)(qie)割(ge)金屬材料(liao)通常(chang)都采(cai)用(yong)轉移型電弧(hu)。一般的等離(li)(li)(li)子弧(hu)不用(yong)保(bao)護氣(qi)(qi)(qi)(qi)體(ti),工作(zuo)氣(qi)(qi)(qi)(qi)體(ti)和(he)切(qie)(qie)割(ge)氣(qi)(qi)(qi)(qi)體(ti)從同(tong)一噴(pen)嘴內噴(pen)出。引弧(hu)時,噴(pen)出小氣(qi)(qi)(qi)(qi)流離(li)(li)(li)子氣(qi)(qi)(qi)(qi)體(ti)作(zuo)為電離(li)(li)(li)介質(zhi),切(qie)(qie)割(ge)時,則同(tong)時噴(pen)出大氣(qi)(qi)(qi)(qi)流氣(qi)(qi)(qi)(qi)體(ti)以排除熔(rong)化金屬,工作(zuo)氣(qi)(qi)(qi)(qi)體(ti)通常(chang)選用(yong)氮氣(qi)(qi)(qi)(qi)。切(qie)(qie)割(ge)薄金屬板材時,可采(cai)用(yong)微(wei)束等離(li)(li)(li)子弧(hu)來(lai)獲得更(geng)窄的割(ge)口。

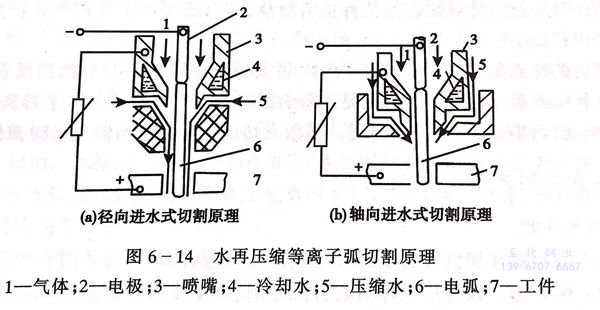

水(shui)(shui)再(zai)壓縮等(deng)離(li)子(zi)弧切(qie)割(ge)時(shi),由割(ge)槍噴(pen)出的除工(gong)作氣體外,還伴隨有(you)高(gao)速(su)流動的水(shui)(shui)束,共(gong)同迅(xun)速(su)地將熔化金(jin)(jin)屬排開(kai)。其切(qie)割(ge)原理如圖6-14所示(shi)。噴(pen)出噴(pen)嘴的高(gao)速(su)水(shui)(shui)流有(you)兩種(zhong)(zhong)進水(shui)(shui)型式。一種(zhong)(zhong)為高(gao)壓水(shui)(shui)流徑向進入噴(pen)嘴孔(kong)道后再(zai)從割(ge)槍噴(pen)出;另一種(zhong)(zhong)為軸向進入嘴外圍后以(yi)環形(xing)水(shui)(shui)流從割(ge)槍噴(pen)出。水(shui)(shui)再(zai)壓縮等(deng)離(li)子(zi)弧切(qie)割(ge)的水(shui)(shui)噴(pen)濺嚴重(zhong),一般在水(shui)(shui)槽中(zhong)進行,工(gong)件(jian)(jian)位于(yu)水(shui)(shui)面下(xia)200mm左右。切(qie)割(ge)時(shi),利用水(shui)(shui)的特性,可(ke)以(yi)使切(qie)割(ge)噪(zao)聲降低(di)15dB左右,并能吸收切(qie)割(ge)過程中(zhong)所形(xing)成的強烈弧光、金(jin)(jin)屬粒子(zi)、灰塵、煙氣、紫(zi)外線等(deng),大(da)大(da)地改善了操作工(gong)的工(gong)作條件(jian)(jian)。水(shui)(shui)還能冷卻工(gong)件(jian)(jian),使割(ge)口(kou)平整和割(ge)后工(gong)件(jian)(jian)熱變形(xing)減小(xiao),割(ge)口(kou)寬度也(ye)比一般等(deng)離(li)子(zi)弧切(qie)割(ge)的割(ge)口(kou)窄。

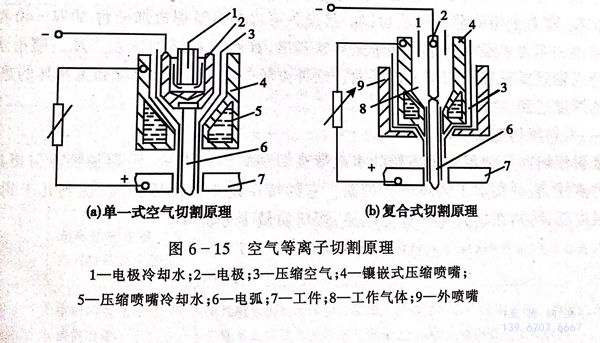

空(kong)(kong)(kong)氣(qi)(qi)(qi)(qi)等(deng)(deng)離(li)(li)(li)(li)子弧(hu)(hu)切(qie)(qie)割(ge)(ge)有兩種(zhong)型式(shi)(shi)(shi)。圖6-15(a)為(wei)(wei)單一空(kong)(kong)(kong)氣(qi)(qi)(qi)(qi)式(shi)(shi)(shi)等(deng)(deng)離(li)(li)(li)(li)子弧(hu)(hu)切(qie)(qie)割(ge)(ge)原理圖,它利用(yong)空(kong)(kong)(kong)氣(qi)(qi)(qi)(qi)壓(ya)縮(suo)機提供的(de)(de)壓(ya)縮(suo)空(kong)(kong)(kong)氣(qi)(qi)(qi)(qi)作(zuo)(zuo)為(wei)(wei)工作(zuo)(zuo)氣(qi)(qi)(qi)(qi)體(ti)(ti)和排除(chu)熔(rong)化(hua)金屬(shu)的(de)(de)氣(qi)(qi)(qi)(qi)流。這(zhe)種(zhong)型式(shi)(shi)(shi)的(de)(de)空(kong)(kong)(kong)氣(qi)(qi)(qi)(qi)等(deng)(deng)離(li)(li)(li)(li)子弧(hu)(hu)切(qie)(qie)割(ge)(ge)的(de)(de)成(cheng)本低,氣(qi)(qi)(qi)(qi)體(ti)(ti)來源方便。壓(ya)縮(suo)空(kong)(kong)(kong)氣(qi)(qi)(qi)(qi)在電(dian)(dian)弧(hu)(hu)中加熱(re)后(hou)分解和電(dian)(dian)離(li)(li)(li)(li),生(sheng)成(cheng)的(de)(de)氧(yang)(yang)與切(qie)(qie)割(ge)(ge)金屬(shu)產(chan)生(sheng)化(hua)學放熱(re)反應,加快了切(qie)(qie)割(ge)(ge)速(su)度。充分電(dian)(dian)離(li)(li)(li)(li)的(de)(de)空(kong)(kong)(kong)氣(qi)(qi)(qi)(qi)等(deng)(deng)離(li)(li)(li)(li)子體(ti)(ti)的(de)(de)熱(re)焓值高,因而電(dian)(dian)弧(hu)(hu)的(de)(de)能量大,與其他等(deng)(deng)離(li)(li)(li)(li)子弧(hu)(hu)切(qie)(qie)割(ge)(ge)方法相比(bi),其切(qie)(qie)割(ge)(ge)速(su)度快,特(te)別適合于切(qie)(qie)割(ge)(ge)厚(hou)度在30mm以下的(de)(de)碳鋼(gang),也(ye)(ye)可以切(qie)(qie)割(ge)(ge)銅、不(bu)銹鋼(gang)、鋁及其他材料。但(dan)是這(zhe)種(zhong)切(qie)(qie)割(ge)(ge)方法的(de)(de)電(dian)(dian)極(ji)(ji)受到強(qiang)烈的(de)(de)氧(yang)(yang)化(hua)腐蝕,所(suo)以一般采(cai)(cai)用(yong)鑲嵌式(shi)(shi)(shi)純鋯、純鉿電(dian)(dian)極(ji)(ji)而不(bu)能采(cai)(cai)用(yong)鎢電(dian)(dian)極(ji)(ji)或氧(yang)(yang)化(hua)物鎢電(dian)(dian)極(ji)(ji)。即使采(cai)(cai)用(yong)鋯、鉿電(dian)(dian)極(ji)(ji),它的(de)(de)工作(zuo)(zuo)壽命一般也(ye)(ye)只(zhi)在5~10h以內(nei)。另一種(zhong)為(wei)(wei)復合式(shi)(shi)(shi)空(kong)(kong)(kong)氣(qi)(qi)(qi)(qi)等(deng)(deng)離(li)(li)(li)(li)子弧(hu)(hu)切(qie)(qie)割(ge)(ge),其切(qie)(qie)割(ge)(ge)原理如圖6-15(b)所(suo)示。內(nei)噴嘴(zui)內(nei)通入(ru)常用(yong)的(de)(de)工作(zuo)(zuo)氣(qi)(qi)(qi)(qi)體(ti)(ti),外噴嘴(zui)內(nei)通人(ren)壓(ya)縮(suo)空(kong)(kong)(kong)氣(qi)(qi)(qi)(qi)。

這樣(yang),一方面利(li)用壓縮空氣(qi)在切(qie)割區(qu)的化(hua)學放熱(re)反應提高切(qie)割速度(du);另一方面又避免了(le)空氣(qi)與電(dian)極的直接(jie)接(jie)觸,因而可采用純鎢(wu)(wu)電(dian)極或(huo)氧化(hua)物(wu)鎢(wu)(wu)電(dian)極,簡化(hua)了(le)電(dian)極結構。