填料室的修理,包括填料更換和填料函部分的修理。高清下載香蕉視頻app蘋果:閥門填料應定期更換,小型閥門只要將繩狀填料按順時針方向順閥桿裝入填料室內,上緊壓蓋螺母即可。大型閥門填料最好采用方形斷面的,也可采用圓形的,壓入前應預先切成圈,接頭必須平整、無空隙、無凸起現象。選用填料時必須考慮使用條件和介質,一般說來,油浸石棉盤根可用于一定溫度的空氣、蒸汽、水和重油產品,橡膠石棉盤根可用于水、蒸汽和石油產品,石墨石棉盤根可用于高溫高壓條件下,尤以夾銅絲的石墨石棉盤根耐壓力更佳,高溫而又溫度多變的介質可用石棉加鉛盤根,強腐蝕介質可用浸聚四氟乙烯石棉盤根或用聚四氟乙烯編織的盤根。

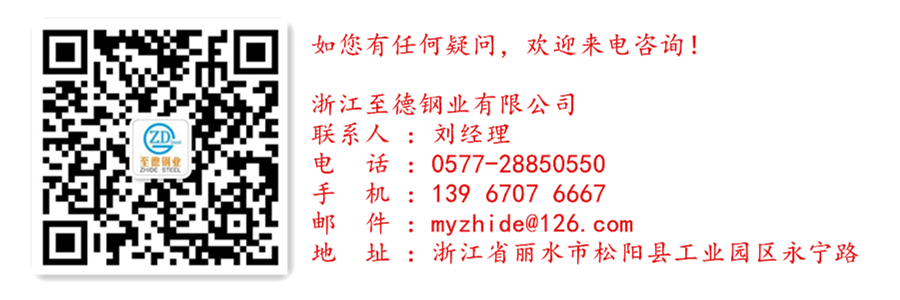

壓緊(jin)填料(liao)室(shi)的(de)(de)壓蓋時(shi),應使壓蓋螺栓同時(shi)、對稱(cheng)地上緊(jin),不(bu)(bu)要傾斜,并應留有供(gong)壓緊(jin)用(yong)的(de)(de)間(jian)隙,如圖(tu)4-64所(suo)示。其間(jian)隙量為:公稱(cheng)尺(chi)寸DN100mm以下的(de)(de)閥(fa)門為20mm;公稱(cheng)尺(chi)寸DN100mm以上的(de)(de)閥(fa)門為30~40mm.壓蓋壓入(ru)填料(liao)室(shi)的(de)(de)深度h不(bu)(bu)能小于填料(liao)室(shi)高度的(de)(de)10%,也不(bu)(bu)能大(da)于20%.

壓緊填料(liao)(liao)時,應(ying)(ying)同(tong)時轉動閥(fa)桿,以(yi)保(bao)(bao)持四周(zhou)均勻,并防止壓得太(tai)死。加填料(liao)(liao)除應(ying)(ying)保(bao)(bao)證密(mi)封良好外,尚應(ying)(ying)保(bao)(bao)證閥(fa)桿轉動靈(ling)活。閥(fa)門(men)的(de)填料(liao)(liao)室如(ru)在工作時有輕微泄漏,可將(jiang)閥(fa)門(men)關閉(bi),再緊一緊填料(liao)(liao)壓蓋;如(ru)泄漏嚴(yan)重(zhong),則應(ying)(ying)將(jiang)填料(liao)(liao)全部(bu)更換。

填料的切制方法有手工(gong)(gong)。工(gong)(gong)具和(he)機械切制三種。

1. 手工切(qie)制

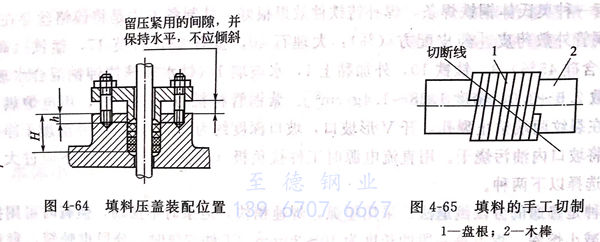

目前(qian)常用一(yi)根(gen)(gen)(gen)(gen)盤根(gen)(gen)(gen)(gen)填料(liao)(liao)作試樣(yang)進行單根(gen)(gen)(gen)(gen)切(qie)(qie)(qie)制(zhi),這樣(yang)會使填料(liao)(liao)的長度(du)(du)(du)(du)或角(jiao)度(du)(du)(du)(du)不(bu)同。填料(liao)(liao)的手(shou)工切(qie)(qie)(qie)制(zhi)如圖4-65所示,先備一(yi)根(gen)(gen)(gen)(gen)與(yu)閥桿直徑相等(deng)的木棒,將盤根(gen)(gen)(gen)(gen)緊緊纏繞在(zai)木棒上,切(qie)(qie)(qie)制(zhi)的角(jiao)度(du)(du)(du)(du)為30°或45°,切(qie)(qie)(qie)制(zhi)的刀刃應薄而鋒利,也可用細(xi)齒鋸條鋸割(ge),用此(ci)方(fang)法切(qie)(qie)(qie)制(zhi)的盤根(gen)(gen)(gen)(gen),其角(jiao)度(du)(du)(du)(du)和(he)長度(du)(du)(du)(du)均能(neng)一(yi)致,精度(du)(du)(du)(du)和(he)質量(liang)都(dou)較好。該方(fang)法的不(bu)足(zu)之(zhi)處是需要專用木棒,切(qie)(qie)(qie)割(ge)線為弧形,切(qie)(qie)(qie)割(ge)不(bu)方(fang)便,切(qie)(qie)(qie)制(zhi)方(fang)法不(bu)當時,纏繞在(zai)木棒上的盤根(gen)(gen)(gen)(gen)容易松(song)散(san)。最好采用小鐵(tie)釘固定,切(qie)(qie)(qie)制(zhi)時,需一(yi)起割(ge)斷。

2. 工(gong)具切制

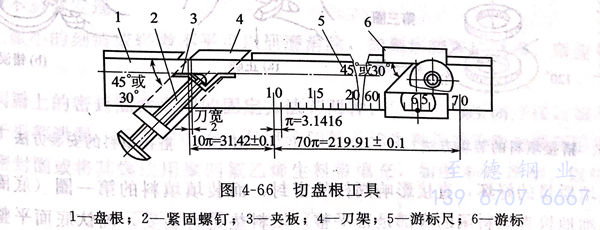

切(qie)盤(pan)(pan)根(gen)工(gong)具如圖4-66所示。該工(gong)具結構(gou)簡(jian)單(dan),攜帶方便,切(qie)制角(jiao)度(du)(du)(du)和長度(du)(du)(du)準確,無切(qie)口毛頭或盤(pan)(pan)根(gen)松散(san)變(bian)形(xing)等缺陷(xian),制作(zuo)(zuo)質量高。切(qie)盤(pan)(pan)根(gen)工(gong)具上(shang)(shang)的游標尺上(shang)(shang)有(you)刻度(du)(du)(du),每格刻度(du)(du)(du)值為(wei)3.14mm,作(zuo)(zuo)測量盤(pan)(pan)根(gen)長度(du)(du)(du)用(yong)。游標可在標尺上(shang)(shang)滑動,上(shang)(shang)面(mian)有(you)45°或30°的凹角(jiao),其頂(ding)點正好在看窗刻度(du)(du)(du)上(shang)(shang),看窗是對(dui)刻度(du)(du)(du)用(yong)的,游標上(shang)(shang)的緊固(gu)螺(luo)釘作(zuo)(zuo)固(gu)定游標用(yong)。游標尺的截面(mian)為(wei)L形(xing),凸邊(bian)起校直盤(pan)(pan)根(gen)的作(zuo)(zuo)用(yong)。刀架外形(xing)為(wei)U形(xing),角(jiao)度(du)(du)(du)與(yu)游標上(shang)(shang)的角(jiao)度(du)(du)(du)對(dui)應相(xiang)等。緊固(gu)螺(luo)桿和夾板活絡(luo)連接,作(zuo)(zuo)夾持盤(pan)(pan)根(gen)用(yong)。

盤(pan)(pan)根(gen)(gen)切(qie)制時(shi),按閥(fa)(fa)桿直徑(jing)與(yu)填料寬度(du)之(zhi)和,在游標(biao)(biao)尺上取(qu)相對(dui)值,再將游標(biao)(biao)滑動到該(gai)值上,對(dui)準看窗上的刻度(du)線,并(bing)用緊(jin)(jin)固(gu)螺釘(ding)固(gu)定游標(biao)(biao)。例如閥(fa)(fa)桿直徑(jing)為(wei)20mm,盤(pan)(pan)根(gen)(gen)寬度(du)6mm,其和為(wei)26mm,對(dui)準游標(biao)(biao)尺上26格,切(qie)下的盤(pan)(pan)根(gen)(gen)長度(du)就是(shi)所需長度(du),即(ji)26π=81.68mm.切(qie)制時(shi)將盤(pan)(pan)根(gen)(gen)夾(jia)(jia)(jia)緊(jin)(jin),用薄(bo)刀(dao)沿刀(dao)架邊切(qie)斷(duan)(duan)。然后將盤(pan)(pan)根(gen)(gen)切(qie)角插入(ru)游標(biao)(biao)凹(ao)角內對(dui)準,盤(pan)(pan)根(gen)(gen)靠在游標(biao)(biao)尺凸邊校(xiao)直,用夾(jia)(jia)(jia)板(ban)夾(jia)(jia)(jia)緊(jin)(jin),再用薄(bo)刀(dao)沿刀(dao)架切(qie)斷(duan)(duan)盤(pan)(pan)根(gen)(gen)。

3. 機(ji)械切制(zhi)

在修理閥門的(de)過程中,對(dui)非(fei)標準(zhun)的(de)填(tian)料或無(wu)法(fa)購買(mai)到的(de)填(tian)料,需要現制現用(yong)。特別是對(dui)常用(yong)的(de)V形塑(su)料填(tian)料,除用(yong)模具注塑(su)成形外,還可用(yong)車(che)制方法(fa)。

在車(che)制V形填(tian)料時(shi),應(ying)選(xuan)用有(you)一定精度(du)的小型車(che)床(chuang),可(ke)采用成(cheng)形車(che)刀加工。應(ying)特別(bie)注(zhu)意各型填(tian)料中相互配合的尺寸和(he)角度(du),并(bing)應(ying)符合粗糙度(du)的要求。

另(ling)外,填(tian)(tian)料(liao)函(han)和(he)填(tian)(tian)料(liao)底部(bu)的填(tian)(tian)料(liao)墊多半為金(jin)屬,也需要進行車加工配制。選用(yong)(yong)填(tian)(tian)料(liao)時,必須考慮使用(yong)(yong)條件和(he)介(jie)質(zhi),一般說(shuo)來,油(you)(you)浸(jin)石(shi)(shi)(shi)棉(mian)(mian)(mian)盤(pan)(pan)(pan)根(gen)(gen)(gen)(gen)可(ke)(ke)用(yong)(yong)于(yu)一定溫(wen)度(du)的空氣、蒸汽、水和(he)重油(you)(you)產品;橡膠石(shi)(shi)(shi)棉(mian)(mian)(mian)盤(pan)(pan)(pan)根(gen)(gen)(gen)(gen)可(ke)(ke)用(yong)(yong)于(yu)水、蒸汽和(he)石(shi)(shi)(shi)油(you)(you)產品;石(shi)(shi)(shi)墨石(shi)(shi)(shi)棉(mian)(mian)(mian)盤(pan)(pan)(pan)根(gen)(gen)(gen)(gen)可(ke)(ke)用(yong)(yong)于(yu)水、蒸汽和(he)石(shi)(shi)(shi)油(you)(you)產品;石(shi)(shi)(shi)墨石(shi)(shi)(shi)棉(mian)(mian)(mian)盤(pan)(pan)(pan)根(gen)(gen)(gen)(gen)可(ke)(ke)用(yong)(yong)于(yu)高溫(wen)高壓條件下,尤以(yi)夾銅絲的石(shi)(shi)(shi)墨石(shi)(shi)(shi)棉(mian)(mian)(mian)盤(pan)(pan)(pan)根(gen)(gen)(gen)(gen)耐(nai)壓力(li)更佳;高溫(wen)而(er)又溫(wen)度(du)多變(bian)的介(jie)質(zhi)可(ke)(ke)用(yong)(yong)石(shi)(shi)(shi)棉(mian)(mian)(mian)加鉛盤(pan)(pan)(pan)根(gen)(gen)(gen)(gen);強腐蝕介(jie)質(zhi)可(ke)(ke)用(yong)(yong)浸(jin)聚四氟(fu)乙烯石(shi)(shi)(shi)棉(mian)(mian)(mian)盤(pan)(pan)(pan)根(gen)(gen)(gen)(gen)或用(yong)(yong)聚四氟(fu)乙烯編織(zhi)的盤(pan)(pan)(pan)根(gen)(gen)(gen)(gen)。

裝填(tian)前,無石(shi)(shi)墨的石(shi)(shi)棉填(tian)料應涂上一(yi)層鱗片狀石(shi)(shi)墨粉,填(tian)料袋裝或(huo)盒(he)裝,保持干凈。

石墨、密封膠(jiao)應分別用盒(he)裝(zhuang)上蓋,不能混(hun)入(ru)雜物。填料、石墨、密封膠(jiao)隨用隨取,不得亂丟(diu)。

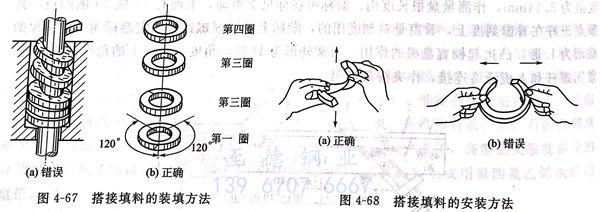

凡(fan)是能(neng)在閥(fa)桿(gan)上(shang)端套(tao)人填(tian)(tian)(tian)料(liao)的(de)(de)閥(fa)門,都(dou)應盡(jin)可能(neng)采取直接(jie)套(tao)入的(de)(de)方法(fa)裝填(tian)(tian)(tian)填(tian)(tian)(tian)料(liao)。套(tao)入后,可用壓(ya)具(ju)或卡箍借助閥(fa)桿(gan)轉動壓(ya)緊填(tian)(tian)(tian)料(liao)。對于不能(neng)直接(jie)套(tao)入的(de)(de)填(tian)(tian)(tian)料(liao),應切成搭(da)(da)接(jie)形式,這種(zhong)搭(da)(da)接(jie)方式對于O形圈和V形填(tian)(tian)(tian)料(liao)都(dou)是絕對禁止(zhi)的(de)(de),必要時(shi)柔性石(shi)墨(mo)填(tian)(tian)(tian)料(liao)也可采取搭(da)(da)接(jie)的(de)(de)方式。圖4-67為(wei)(wei)搭(da)(da)接(jie)填(tian)(tian)(tian)料(liao)的(de)(de)裝填(tian)(tian)(tian)方法(fa),將搭(da)(da)接(jie)口上(shang)下(xia)錯(cuo)開,傾斜后把填(tian)(tian)(tian)料(liao)套(tao)在閥(fa)桿(gan)上(shang),然后上(shang)下(xia)復原,使(shi)(shi)切口吻合,輕(qing)輕(qing)地嵌(qian)入填(tian)(tian)(tian)料(liao)函(han)中。圖4-68(b)為(wei)(wei)錯(cuo)誤(wu)的(de)(de)方法(fa),它容(rong)易使(shi)(shi)填(tian)(tian)(tian)料(liao)變形,甚至拉裂,對于柔性石(shi)墨(mo)填(tian)(tian)(tian)料(liao),更應禁止(zhi)這種(zhong)錯(cuo)誤(wu)操作(zuo)。

填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)裝(zhuang)填(tian)(tian)(tian)(tian)(tian)質量的(de)(de)(de)好壞,直接(jie)影響閥(fa)桿的(de)(de)(de)密封,而裝(zhuang)填(tian)(tian)(tian)(tian)(tian)填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)的(de)(de)(de)第(di)一(yi)圈(quan)(quan)(quan)(底(di)圈(quan)(quan)(quan))是(shi)(shi)關鍵,要(yao)再認真仔細地檢查(cha)填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)函的(de)(de)(de)底(di)部是(shi)(shi)否(fou)(fou)平整,填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)墊(dian)是(shi)(shi)否(fou)(fou)裝(zhuang)妥,確認底(di)面平整無歪斜時(shi),再將第(di)一(yi)圈(quan)(quan)(quan)填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)用(yong)壓(ya)具(ju)輕(qing)(qing)輕(qing)(qing)地壓(ya)下底(di)面,抽出壓(ya)具(ju);檢查(cha)填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)是(shi)(shi)否(fou)(fou)平整,有無歪斜,搭接(jie)吻合是(shi)(shi)否(fou)(fou)良好,再以(yi)壓(ya)具(ju)將第(di)一(yi)圈(quan)(quan)(quan)填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)壓(ya)緊,但用(yong)力要(yao)適(shi)當,不(bu)能太大(da)。應一(yi)圈(quan)(quan)(quan)一(yi)圈(quan)(quan)(quan)地裝(zhuang)入(ru)填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)函中,并且(qie)每(mei)裝(zhuang)一(yi)圈(quan)(quan)(quan)就壓(ya)緊一(yi)次,并應在每(mei)層填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)間加(jia)少許(xu)銀色石墨(mo)粉。不(bu)應連裝(zhuang)幾圈(quan)(quan)(quan),一(yi)次壓(ya)緊,更(geng)不(bu)得使(shi)許(xu)多(duo)圈(quan)(quan)(quan)連成一(yi)條繞入(ru)填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)函中,這(zhe)種裝(zhuang)填(tian)(tian)(tian)(tian)(tian)法(fa)只能作臨(lin)時(shi)試(shi)壓(ya)作業用(yong),不(bu)允許(xu)用(yong)作正常運行閥(fa)門(men)的(de)(de)(de)密封填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)裝(zhuang)填(tian)(tian)(tian)(tian)(tian)方式。正確的(de)(de)(de)方法(fa)是(shi)(shi)將各圈(quan)(quan)(quan)填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)的(de)(de)(de)切口搭接(jie)位置(zhi),相(xiang)互(hu)錯(cuo)開120°,這(zhe)是(shi)(shi)目前(qian)普(pu)遍采用(yong)的(de)(de)(de)裝(zhuang)填(tian)(tian)(tian)(tian)(tian)方法(fa)。也(ye)(ye)有其(qi)他填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)搭口錯(cuo)位方式,如填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)各圈(quan)(quan)(quan)搭口互(hu)錯(cuo)90°,也(ye)(ye)有90°和180°交互(hu)錯(cuo)開。在裝(zhuang)填(tian)(tian)(tian)(tian)(tian)填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)的(de)(de)(de)過程中,每(mei)裝(zhuang)1~2圈(quan)(quan)(quan)應旋轉一(yi)下閥(fa)桿,以(yi)檢查(cha)閥(fa)桿與填(tian)(tian)(tian)(tian)(tian)料(liao)(liao)(liao)(liao)是(shi)(shi)否(fou)(fou)卡阻,而影響閥(fa)門(men)的(de)(de)(de)啟(qi)閉。

選擇填(tian)料(liao)(liao)規格時(shi),嚴(yan)禁以小代大,沒有合適寬度的(de)填(tian)料(liao)(liao)時(shi),允(yun)許(xu)用比填(tian)料(liao)(liao)函(han)(han)槽寬1~2mm的(de)填(tian)料(liao)(liao),但不(bu)允(yun)許(xu)用手錘打扁,而應(ying)用平板或碾(nian)子均勻(yun)地壓扁填(tian)料(liao)(liao)。壓制后的(de)填(tian)料(liao)(liao),如發現有質量(liang)問題(ti),應(ying)停止(zhi)使用。設有分(fen)流環(huan)的(de)填(tian)料(liao)(liao)函(han)(han),應(ying)事先測量(liang)好填(tian)料(liao)(liao)函(han)(han)深度和分(fen)流環(huan)的(de)位置。分(fen)流環(huan)要對準填(tian)料(liao)(liao)函(han)(han)的(de)引流管(guan)孔,允(yun)許(xu)稍微偏(pian)上,不(bu)準偏(pian)下。

填(tian)(tian)料(liao)(liao)函基本裝填(tian)(tian)滿后,應以壓(ya)蓋(gai)(gai)壓(ya)緊(jin)填(tian)(tian)料(liao)(liao)。操作(zuo)時(shi)(shi),兩邊螺栓對稱擰緊(jin),用(yong)力均(jun)勻(yun),壓(ya)蓋(gai)(gai)不得歪斜,以免(mian)填(tian)(tian)料(liao)(liao)壓(ya)偏或壓(ya)蓋(gai)(gai)接觸閥(fa)桿(gan)(gan),增加(jia)閥(fa)桿(gan)(gan)摩擦阻力,壓(ya)套(tao)壓(ya)人填(tian)(tian)料(liao)(liao)函內(nei),也可以一(yi)圈填(tian)(tian)料(liao)(liao)的高度作(zuo)為(wei)壓(ya)套(tao)壓(ya)入(ru)的深度,一(yi)般壓(ya)入(ru)深度不得小(xiao)于5mm,并且隨(sui)時(shi)(shi)檢查閥(fa)桿(gan)(gan)與壓(ya)蓋(gai)(gai)、壓(ya)套(tao)以及填(tian)(tian)料(liao)(liao)函三者(zhe)的間隙要(yao)一(yi)致,轉動閥(fa)桿(gan)(gan)時(shi)(shi),受力均(jun)勻(yun)正(zheng)常、操作(zuo)靈活、無(wu)卡阻現象。如果(guo)手感操作(zuo)力矩過大時(shi)(shi),可適當放松壓(ya)蓋(gai)(gai),減小(xiao)填(tian)(tian)料(liao)(liao)對閥(fa)門桿(gan)(gan)的摩擦阻力。

V形(xing)填(tian)(tian)(tian)(tian)料(liao)和模壓成形(xing)的(de)其他填(tian)(tian)(tian)(tian)料(liao),應從(cong)閥(fa)(fa)桿(gan)(gan)上(shang)端慢(man)慢(man)套入(ru),套裝時要注意(yi)防止填(tian)(tian)(tian)(tian)料(liao)內圈(quan)被閥(fa)(fa)桿(gan)(gan)的(de)螺紋劃(hua)傷。成形(xing)V形(xing)填(tian)(tian)(tian)(tian)料(liao)的(de)下(xia)(xia)(xia)填(tian)(tian)(tian)(tian)料(liao)(填(tian)(tian)(tian)(tian)料(liao)墊)凸角(jiao)向(xiang)(xiang)上(shang),安(an)(an)放在(zai)填(tian)(tian)(tian)(tian)料(liao)函(han)底面;中(zhong)填(tian)(tian)(tian)(tian)料(liao)凹角(jiao)向(xiang)(xiang)下(xia)(xia)(xia),凸角(jiao)向(xiang)(xiang)上(shang),安(an)(an)放于填(tian)(tian)(tian)(tian)料(liao)中(zhong)部(bu);上(shang)填(tian)(tian)(tian)(tian)料(liao)凹角(jiao)向(xiang)(xiang)下(xia)(xia)(xia),平面向(xiang)(xiang)上(shang),安(an)(an)放在(zai)填(tian)(tian)(tian)(tian)料(liao)函(han)的(de)上(shang)層(ceng)。

填料函(han)一般不(bu)需修(xiu)(xiu)理,但閥門使用后若有(you)腐蝕(shi)(shi)現象或有(you)雜物(wu)黏附,修(xiu)(xiu)理時要(yao)清理擦拭,用砂布(bu)磨光,腐蝕(shi)(shi)嚴重(zhong),出現麻坑者,應在(zai)車床上車去不(bu)平(ping)的(de)表面。