1. 管坯預旋(xuan)轉(zhuan)裝置

大型的不銹鋼管(guan)穿孔機組,管坯直徑大如ф350mm、φ380mm、φ450mm、φ500mm,管坯重量大,為方便管坯咬入,防止前卡事故,在前臺設置了管坯預旋轉裝置,大管坯在推鋼機推入軋輥前在預旋轉的驅動下旋轉起來,這樣很大程度改善了咬入條件,減少了事故,提高了軋輥壽命。國內攀成鋼ф340mm機組、湖北新冶鋼φ460mm機組、天淮φ508mm機組均采用了管坯預旋轉,使用效果良好。見圖6-37所示。

2. 關于主電機、傳動軸擺放的位置

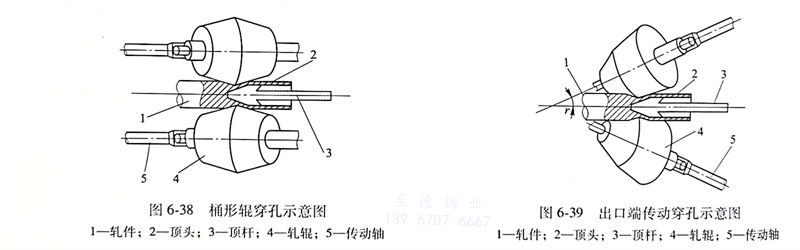

桶(tong)形(xing)(xing)輥(gun)穿(chuan)孔(kong)(kong)(kong)機(ji)(ji)均是(shi)電(dian)(dian)機(ji)(ji)、傳(chuan)(chuan)動(dong)(dong)(dong)(dong)軸擺放(fang)(fang)在(zai)前(qian)臺,如寶鋼(gang)改造前(qian)的(de)(de)φ140mm穿(chuan)孔(kong)(kong)(kong)機(ji)(ji)、天(tian)津鋼(gang)管的(de)(de)φ250mm穿(chuan)孔(kong)(kong)(kong)機(ji)(ji)以及為自(zi)動(dong)(dong)(dong)(dong)軋(ya)(ya)(ya)(ya)管配套(tao)的(de)(de)桶(tong)形(xing)(xing)輥(gun)穿(chuan)孔(kong)(kong)(kong)機(ji)(ji)等。錐(zhui)(zhui)形(xing)(xing)輥(gun)穿(chuan)孔(kong)(kong)(kong)機(ji)(ji)由于(yu)采用(yong)(yong)(yong)了大輾軋(ya)(ya)(ya)(ya)角(10°~15°,多數采用(yong)(yong)(yong)15°),因此,絕(jue)大多數錐(zhui)(zhui)形(xing)(xing)輥(gun)穿(chuan)孔(kong)(kong)(kong)機(ji)(ji)是(shi)將(jiang)(jiang)電(dian)(dian)機(ji)(ji)、傳(chuan)(chuan)動(dong)(dong)(dong)(dong)軸放(fang)(fang)在(zai)后臺。衡陽(yang)鋼(gang)管的(de)(de)φ89mm機(ji)(ji)組(zu),為有(you)利于(yu)穿(chuan)孔(kong)(kong)(kong)機(ji)(ji)實現(xian)頂桿循環(huan)和設備(bei)維護,將(jiang)(jiang)錐(zhui)(zhui)形(xing)(xing)輥(gun)穿(chuan)孔(kong)(kong)(kong)機(ji)(ji)電(dian)(dian)機(ji)(ji)、傳(chuan)(chuan)動(dong)(dong)(dong)(dong)軸放(fang)(fang)在(zai)了前(qian)臺(輾軋(ya)(ya)(ya)(ya)角為10°)。鞍鋼(gang)ф159mm機(ji)(ji)組(zu)建設時,將(jiang)(jiang)桶(tong)形(xing)(xing)輥(gun)改為錐(zhui)(zhui)形(xing)(xing)輥(gun),輾軋(ya)(ya)(ya)(ya)角為3.3°,電(dian)(dian)機(ji)(ji)、傳(chuan)(chuan)動(dong)(dong)(dong)(dong)軸放(fang)(fang)仍放(fang)(fang)在(zai)前(qian)臺。將(jiang)(jiang)電(dian)(dian)機(ji)(ji)、傳(chuan)(chuan)動(dong)(dong)(dong)(dong)軸擺放(fang)(fang)于(yu)前(qian)臺,有(you)利于(yu)操作(zuo)環(huan)境的(de)(de)優化,有(you)利于(yu)設備(bei)的(de)(de)維護。近(jin)年來國(guo)內(nei)的(de)(de)一些小(xiao)型穿(chuan)孔(kong)(kong)(kong)機(ji)(ji)的(de)(de)改造,均采用(yong)(yong)(yong)了小(xiao)錐(zhui)(zhui)角的(de)(de)錐(zhui)(zhui)形(xing)(xing)穿(chuan)孔(kong)(kong)(kong)機(ji)(ji),電(dian)(dian)機(ji)(ji)、傳(chuan)(chuan)動(dong)(dong)(dong)(dong)軸放(fang)(fang)仍放(fang)(fang)在(zai)前(qian)臺。

3. 頂桿的運行方式

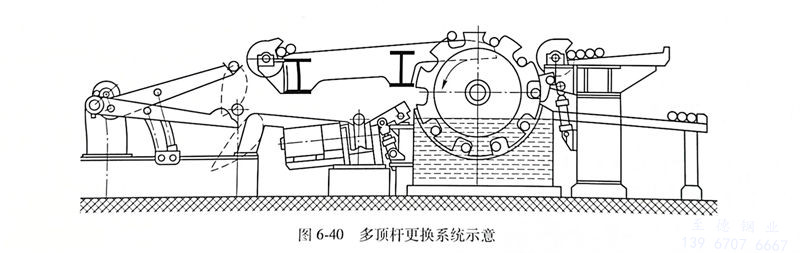

我國早期(qi)穿孔(kong)機(ji)頂(ding)(ding)(ding)(ding)(ding)桿(gan)(gan)運行方式均(jun)采(cai)用(yong)單支運行,寶鋼(gang)引進的(de)(de)φ140mm機(ji)組(zu)采(cai)用(yong)多(duo)支頂(ding)(ding)(ding)(ding)(ding)桿(gan)(gan)(8~11支)線外循環,頂(ding)(ding)(ding)(ding)(ding)桿(gan)(gan)冷(leng)卻更換機(ji)構見圖(tu)6-40。衡陽鋼(gang)管(guan)的(de)(de)89mm機(ji)組(zu)頂(ding)(ding)(ding)(ding)(ding)桿(gan)(gan)也是8~11支,這種(zhong)(zhong)運行方式多(duo)用(yong)于高節奏的(de)(de)全浮(fu)動(dong)式、半浮(fu)動(dong)式機(ji)組(zu),軋制節奏可以滿(man)足3.5~49/min。這種(zhong)(zhong)運行方式占地面積大(da),配備的(de)(de)頂(ding)(ding)(ding)(ding)(ding)桿(gan)(gan)多(duo)(投(tou)入大(da)),更換規(gui)格(ge)時費時費力(li)。但這種(zhong)(zhong)頂(ding)(ding)(ding)(ding)(ding)桿(gan)(gan)運行方式使頂(ding)(ding)(ding)(ding)(ding)頭、頂(ding)(ding)(ding)(ding)(ding)桿(gan)(gan)冷(leng)卻效果(guo)好,可滿(man)足高節奏的(de)(de)軋管(guan)機(ji)組(zu)。隨(sui)著限動(dong)軋機(ji)占有主導地位后,單支頂(ding)(ding)(ding)(ding)(ding)桿(gan)(gan)運行成為主流(liu),并(bing)在頂(ding)(ding)(ding)(ding)(ding)頭、頂(ding)(ding)(ding)(ding)(ding)桿(gan)(gan)內外冷(leng)卻方面開發了很多(duo)新(xin)技術。

4. 頂桿預選轉

天津不銹鋼管廠φ250mm連軋管機組、成都無縫ф180mm精密軋管機組,都采用頂桿預選轉機構。頂桿預選轉有利于穿孔時管坯咬入,有利于減少穿孔前卡,尤其是針對大管坯穿孔,天津不(bu)銹鋼管(guan)廠Φ460mm PQF機組也采用頂桿預選轉,但是由于頂桿預選轉機構維護成本較高,沒能在國內較大范圍推廣。

5. 頂桿小車驅動方(fang)式

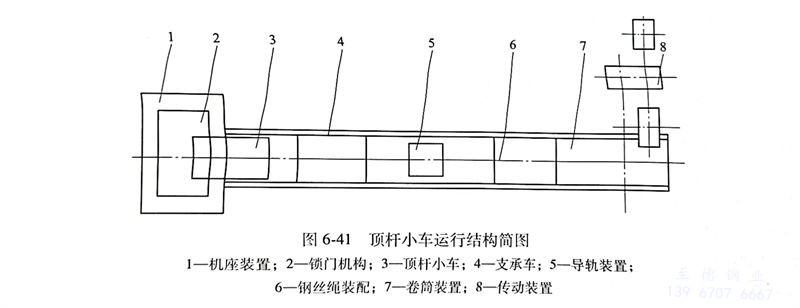

頂桿止推小車的運行多采用鋼絲繩卷筒拖動,靠液壓缸張緊鋼絲繩保證小車運行的定位,這種方式投資少,維護簡單,但不能滿足高節奏的需要,見圖6-41。天津不(bu)銹(xiu)鋼管廠φ168mmPQF機組,穿孔機采用了帶有齒條驅動的頂桿止推小車,這種小車的運行,啟、停速度快、定位精度高,最高節奏可以保證24秒/根。

6. 頂頭的連接方式及頂頭冷(leng)卻

頂頭與頂桿的連(lian)接方式:

a. 一(yi)種是螺(luo)紋連接,頂頭冷卻(que)采用(yong)(yong)內外水冷,單個頂頭連續使用(yong)(yong);

b. 另(ling)一種是銷子連接,多支頂桿(gan)(gan)成組循環使用,頂頭、頂桿(gan)(gan)線外冷卻,多用于頂桿(gan)(gan)快(kuai)速更換(huan)的高節奏機組;

c. 還有(you)一(yi)種是頂(ding)(ding)(ding)頭頂(ding)(ding)(ding)桿不固定連接,采用頂(ding)(ding)(ding)頭快速(su)更換方式如天津鋼管的(de)(de)φ168mm機組,引進了(le)三頂(ding)(ding)(ding)頭快速(su)更換循環使用的(de)(de)頂(ding)(ding)(ding)頭冷卻及更換裝置,滿足了(le)工藝的(de)(de)要(yao)求。但該頂(ding)(ding)(ding)頭更換裝置對(dui)頂(ding)(ding)(ding)桿的(de)(de)定位(wei),頂(ding)(ding)(ding)頭的(de)(de)定位(wei)要(yao)求精度較高。

7. 后臺的定心裝置

穿孔(kong)(kong)機(ji)后(hou)臺定(ding)(ding)(ding)心(xin)的(de)(de)(de)穩定(ding)(ding)(ding)性(xing)直接影(ying)響(xiang)毛管(guan)的(de)(de)(de)壁厚精(jing)度。早期的(de)(de)(de)穿孔(kong)(kong)后(hou)臺定(ding)(ding)(ding)心(xin)輥(gun),采用的(de)(de)(de)是(shi)四(si)輥(gun)定(ding)(ding)(ding)心(xin),氣(qi)動壓緊(jin),對其(qi)頂桿對中性(xing)、穩定(ding)(ding)(ding)性(xing)都較差。20世紀80年代(dai)后(hou),隨著電(dian)控(kong)技(ji)術和液壓技(ji)術的(de)(de)(de)發展,新(xin)建機(ji)組(zu)和改造機(ji)組(zu)普(pu)遍的(de)(de)(de)做法是(shi):

a. 采用液壓系(xi)統實施(shi)對頂桿(gan)的壓緊;

b. 采(cai)用三輥定心裝置(對中性高);

c. 增加定心裝置的架數(shu),一般機(ji)組采用(yong)5~7架;

d. 縮短第一架定心裝置與機(ji)架中心線(xian)的距離。

天津不(bu)銹(xiu)鋼(gang)管廠ф250mm穿孔機的第一架定心裝置安裝在機架內,采用四輥裝置,因強度不夠,經常損壞,維護也不方便。后續建設的機組不再沿用此結構,改成了機架外的三輥定心裝置。設計上將第一架三輥定心向機架方向平移,縮短軋機中心到第一架三輥定心裝置的距離,起到了減少頂桿抖動,保證壁厚精度的作用。