高清下載香蕉視頻app蘋果:不銹鋼的硬度、強度并不高,但其塑性、韌性都較好,熱強性高,切削時切屑不易被切離。在保證刀具有足夠強度的前提下,應選用較大的前角,這樣不僅能夠減小被切削金屬的塑性變形,而且可以降低切削力和切削溫度,同時使硬化層深度減小。

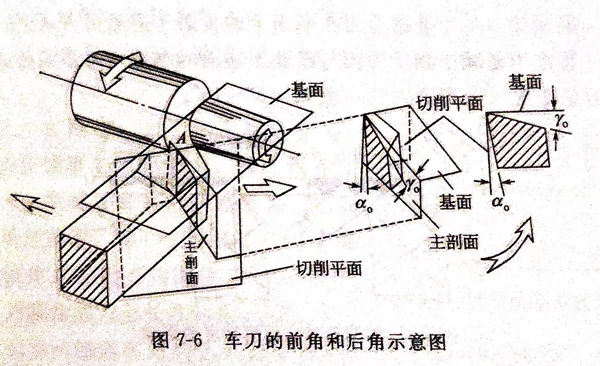

車刀的前角和后(hou)角示意圖,見圖7-6。

車刀(dao)的主(zhu)要角(jiao)度有前角(jiao)、后角(jiao)、主(zhu)偏(pian)角(jiao)和副偏(pian)角(jiao)。為(wei)了確定車刀(dao)的主(zhu)要角(jiao)度,還要建立(li)三個(ge)輔助平面:切(qie)削平面、基面和主(zhu)剖面,見(jian)圖7-6。

①. 切削平面通(tong)過主(zhu)切削刃上一點(如圖中A點),并與切削表面相切的平面。

②. 基面通(tong)過主切削刃(ren)上(shang)一點(dian),并與該(gai)點(dian)的切削平面相垂直的平面。

③. 主(zhu)剖(pou)面通(tong)過主(zhu)切削刃上一點(dian),并(bing)垂直于(yu)主(zhu)切削刃在基(ji)面上的投影所作(zuo)的平面。

車刀的前角和(he)后角是在主剖面(mian)中測量(liang)的。

前(qian)(qian)(qian)(qian)(qian)角(jiao)(jiao)(jiao)(jiao)(Yo)是前(qian)(qian)(qian)(qian)(qian)刀面(mian)(mian)(mian)(mian)(mian)(mian)與(yu)(yu)基面(mian)(mian)(mian)(mian)(mian)(mian)之間的夾角(jiao)(jiao)(jiao)(jiao)。當前(qian)(qian)(qian)(qian)(qian)刀面(mian)(mian)(mian)(mian)(mian)(mian)低于基面(mian)(mian)(mian)(mian)(mian)(mian)時(shi),前(qian)(qian)(qian)(qian)(qian)角(jiao)(jiao)(jiao)(jiao)定為正值(zhi);前(qian)(qian)(qian)(qian)(qian)刀面(mian)(mian)(mian)(mian)(mian)(mian)高于基面(mian)(mian)(mian)(mian)(mian)(mian)時(shi),前(qian)(qian)(qian)(qian)(qian)角(jiao)(jiao)(jiao)(jiao)定為負(fu)值(zhi);前(qian)(qian)(qian)(qian)(qian)刀面(mian)(mian)(mian)(mian)(mian)(mian)與(yu)(yu)基面(mian)(mian)(mian)(mian)(mian)(mian)重合(he)時(shi),前(qian)(qian)(qian)(qian)(qian)角(jiao)(jiao)(jiao)(jiao)為零。較大(da)的前(qian)(qian)(qian)(qian)(qian)角(jiao)(jiao)(jiao)(jiao)可(ke)使刀刃(ren)鋒利,能(neng)減少切屑變(bian)形以(yi)及切屑與(yu)(yu)前(qian)(qian)(qian)(qian)(qian)刀面(mian)(mian)(mian)(mian)(mian)(mian)的摩擦(ca),切削輕(qing)快省力。但前(qian)(qian)(qian)(qian)(qian)角(jiao)(jiao)(jiao)(jiao)太大(da),會降低刀刃(ren)強度,影響刀具(ju)的壽命。用(yong)高速(su)鋼車(che)刀車(che)削碳鋼時(shi),Yo=15°~25°;車(che)削鑄鐵時(shi),前(qian)(qian)(qian)(qian)(qian)角(jiao)(jiao)(jiao)(jiao)可(ke)略(lve)小(xiao)。用(yong)硬質合(he)金車(che)刀車(che)削碳鋼時(shi),γo=10°~20°.精加(jia)工時(shi),前(qian)(qian)(qian)(qian)(qian)角(jiao)(jiao)(jiao)(jiao)可(ke)選得大(da)些(xie),粗加(jia)工時(shi),應選得小(xiao)些(xie)。

后角(ao)是(shi)主后刀面(mian)(mian)與(yu)切削平面(mian)(mian)之間的(de)夾角。后角的(de)作用是(shi)減小后刀面(mian)(mian)與(yu)切削表面(mian)(mian)之間的(de)摩擦,一般可(ke)在60°~120°之間選(xuan)擇,精加工時,后角可(ke)選(xuan)大些。

車刀的主偏角和副偏角是在基面上測量的。

主偏角(jiao)(k1)是(shi)主切(qie)削(xue)刃(ren)在基面上(shang)的(de)(de)投影與進給方向之間(jian)的(de)(de)夾角(jiao)。小的(de)(de)主偏角(jiao)可(ke)增加主切(qie)削(xue)刃(ren)參加切(qie)削(xue)的(de)(de)長度(du),散熱較好,對延長刀(dao)具(ju)耐用(yong)度(du)有利,但加工(gong)細長軸時,刀(dao)具(ju)作用(yong)在工(gong)件(jian)上(shang)的(de)(de)徑(jing)向力增大(da),易使工(gong)件(jian)產生彎曲和振動,影響加工(gong)質(zhi)量。主偏角(jiao)的(de)(de)選擇主要按(an)工(gong)件(jian)剛性(xing)考慮:剛性(xing)好選小值(zhi)(30°~60°);剛性(xing)差選大(da)值(zhi)(75°~90°)。

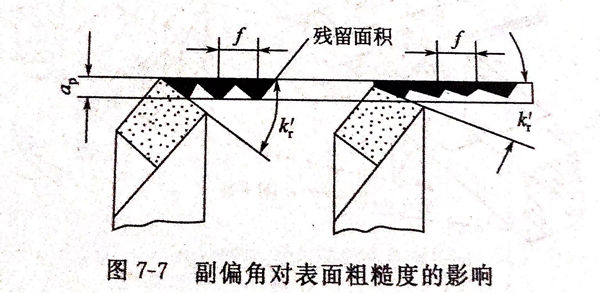

副(fu)偏(pian)角(kr)是副(fu)刀(dao)刃在基面上的(de)(de)投影(ying)與進給反(fan)方向之間的(de)(de)夾(jia)角,其作用是減小副(fu)后刀(dao)面與已加工表面的(de)(de)摩擦,并影(ying)響(xiang)已加工表面的(de)(de)粗糙度(見圖7-7).一(yi)般kr=5°~15°.

①. 車削各(ge)種不(bu)銹(xiu)(xiu)鋼(gang)(gang)的前(qian)(qian)角(jiao)(γo)大(da)致為12°~30°.對(dui)馬氏(shi)體不(bu)銹(xiu)(xiu)鋼(gang)(gang)(如2Cr13),前(qian)(qian)角(jiao)可(ke)取(qu)(qu)(qu)較大(da)值;對(dui)奧氏(shi)體和奧氏(shi)體+鐵(tie)素體不(bu)銹(xiu)(xiu)鋼(gang)(gang),前(qian)(qian)角(jiao)應取(qu)(qu)(qu)較小(xiao)值;對(dui)未(wei)經調(diao)質(zhi)處理或(huo)調(diao)質(zhi)后硬度較低的不(bu)銹(xiu)(xiu)鋼(gang)(gang),可(ke)取(qu)(qu)(qu)較大(da)前(qian)(qian)角(jiao);直徑較小(xiao)或(huo)薄壁工件(jian),宜采用較大(da)的前(qian)(qian)角(jiao)。高(gao)速鋼(gang)(gang)銑(xian)刀(dao)(dao)取(qu)(qu)(qu)gn=10°~20°,硬質(zhi)合金銑(xian)刀(dao)(dao)取(qu)(qu)(qu)gn=5°~10°;鉸(jiao)刀(dao)(dao)一(yi)般(ban)取(qu)(qu)(qu)r.=8°~12°;絲錐(zhui)一(yi)般(ban)取(qu)(qu)(qu)γo=15°~20°(機(ji)用)或(huo)go=20°(手用)。

②. 后(hou)角(jiao)(jiao)(jiao)ao:加(jia)大(da)后(hou)角(jiao)(jiao)(jiao)能減小后(hou)刀面與加(jia)工表面的摩擦,但會使切(qie)削(xue)刃的強度和散熱(re)能力降低。后(hou)角(jiao)(jiao)(jiao)的合理值取決于切(qie)削(xue)厚(hou)度,切(qie)削(xue)厚(hou)度小時,宜(yi)選較大(da)后(hou)角(jiao)(jiao)(jiao)。

不銹(xiu)鋼(gang)車刀(dao)(dao)或(huo)鏜刀(dao)(dao)通常取(qu)(qu)αo=10°~20°(精加工)或(huo)ao=6°~10°(粗(cu)加工);高速鋼(gang)端銑刀(dao)(dao)取(qu)(qu)ao=10°~20°,立銑刀(dao)(dao)取(qu)(qu)ao=15°~20°;硬度合金端銑刀(dao)(dao)取(qu)(qu)ao=5°~10°,立銑刀(dao)(dao)取(qu)(qu)αo=12°~16°;鉸刀(dao)(dao)和絲錐取(qu)(qu)ao=8°~12°.

③. 主(zhu)(zhu)偏(pian)角(jiao)(jiao)kr、副偏(pian)角(jiao)(jiao)kr'和刀(dao)尖圓(yuan)弧re:減小(xiao)主(zhu)(zhu)偏(pian)角(jiao)(jiao)可(ke)增加刀(dao)刃(ren)工作長度,有利于散熱,但在(zai)切(qie)削過(guo)程中使徑向力加大,容易產生振(zhen)動,常取kr=45°~75°,若(ruo)機床(chuang)剛性不(bu)足,可(ke)適當加大。副偏(pian)角(jiao)(jiao)常取kr=8°~15°.為(wei)了(le)加強刀(dao)尖,一般應磨出re=0.5~1.0mm的(de)刀(dao)尖圓(yuan)弧。

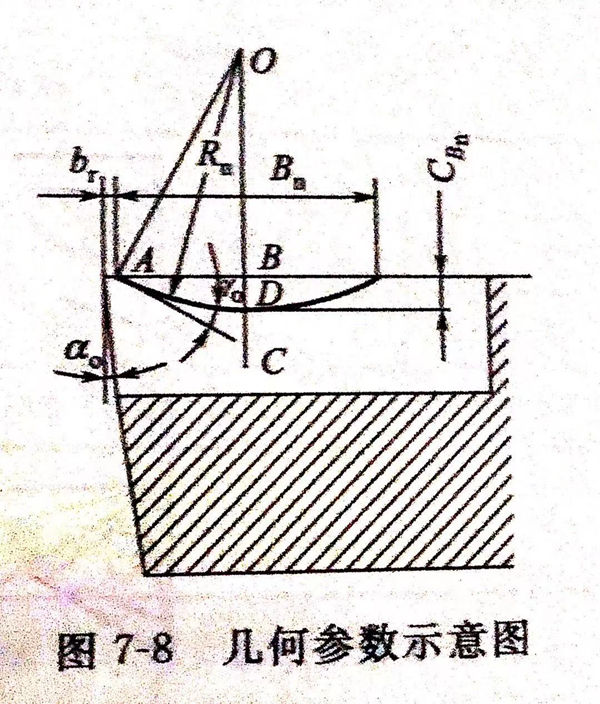

④. 刃(ren)傾角ls:為了增加刀尖(jian)強度,刃(ren)傾角一般(ban)取(qu)ls=-8°~-3°,斷續(xu)切(qie)削時(shi)取(qu)較大值(zhi)ls=-15°~-5°.圖7-8所示為刀具(ju)幾何(he)參(can)數示意圖。

生產實踐(jian)中,為了(le)加大(da)切屑變形,提高(gao)刀(dao)尖強度(du)(du)與散熱能力,采用(yong)雙刃(ren)傾(qing)(qing)角(jiao)車(che)刀(dao),取(qu)得(de)了(le)良好的斷屑效果,也加寬(kuan)了(le)斷屑范圍。第一刃(ren)傾(qing)(qing)角(jiao)ls1≥0°,第二刃(ren)傾(qing)(qing)角(jiao)在(zai)接(jie)近(jin)刀(dao)尖部位,ls2≈-20°,第二刃(ren)傾(qing)(qing)角(jiao)的刀(dao)刃(ren)長度(du)(du)約為ap/3。

當雙刃(ren)傾角(jiao)車刀的γo=20°、αo=6°~8°、kr=90°或(huo)75°、倒(dao)棱前角(jiao)γo,=-10°、刀尖圓弧re=0.15~0.2mm時,在切削速vc=80~100m/min、進(jin)給量 f=0.2~0.3mm/r、切削深度 ap=4~15mm的條件(jian)下(xia)切削,斷(duan)屑效果良好(hao),刀具(ju)耐用度高。

要求(qiu)刀(dao)(dao)(dao)具前后刀(dao)(dao)(dao)面的表面粗糙度值小(xiao),刀(dao)(dao)(dao)具磨鈍標錐VB為加工一般材料(liao)的1/2.