頂(ding)(ding)壓(ya)粘(zhan)接法(fa)(fa)的基本(ben)原理是:在(zai)大于泄漏介質(zhi)壓(ya)力的人為外力作用下,首先(xian)迫使泄漏止住,再利用膠黏劑的特性(xing)對泄漏部位進行粘(zhan)接,待膠黏劑固化后,撤出外力,達(da)到重新密封的目的。頂(ding)(ding)壓(ya)粘(zhan)接法(fa)(fa)的關(guan)鍵(jian)是頂(ding)(ding)壓(ya)工具。

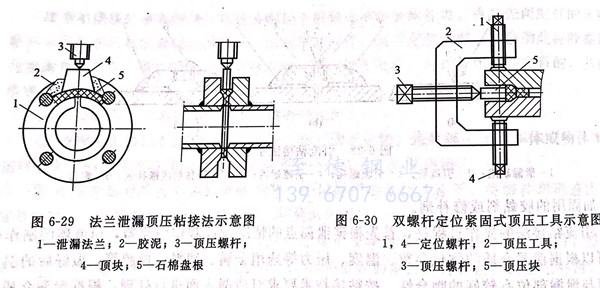

1. 管道法蘭泄漏頂壓工具及操(cao)作方法

當高清下載香蕉視頻app蘋果:不銹鋼法蘭發生點狀泄漏時,采用頂壓粘接法處理過程如下。首先把法蘭頂壓工具固定在泄漏法蘭上,準備好一段石棉盤根,將這段石棉盤根在事先調配好的環氧樹脂膠液中浸透一下,如果泄漏介質能使環氧樹脂溶解,則選擇其他不被泄漏介質所溶解的膠黏劑膠液或修補劑,正對著泄漏處將這段浸膠盤根壓入不銹鋼法蘭連接間隙內(當泄漏量較大或泄漏介質有較強的溶解性、腐蝕性,盤根難以放入時,可以改用鉛條),用錘子將浸膠盤根打入法蘭間隙內,迅速將頂塊4裝好,如圖6-29所示,然后把頂壓螺桿3對準頂塊4的定位圓孔,旋轉頂壓螺桿3,這時通過頂壓螺桿3及頂塊4,就會把浸膠石棉盤根緊緊地壓到泄漏點處,迫使泄漏停止。泄漏一旦止住,就可以對泄漏法蘭按粘接技術的要求進行必要的處理,主要是清除影響粘接效果的油污、疏松的鐵銹及進行脫脂處理,再用事先配制好的膠黏劑膠泥填塞滿頂塊4的周圍,待膠黏劑膠泥完全固化后,撤除頂壓工具。法蘭泄漏的頂壓工具有多種形式。圖6-30所示為雙螺桿定位緊固式,前端有一圓形鋼塊,當螺桿旋轉時,它只做軸向移動而無轉動,這樣它就能很好地把頂壓工具固定在泄漏法蘭上,用兩個這樣的螺桿可以調整頂壓螺桿3的位置,使它能準確地對正泄漏法蘭的間隙處,頂壓螺桿 3 主要作用是把螺旋力通過頂壓塊5及浸膠石棉盤根轉化為止住泄漏的外力,迫使泄漏停止。

2. 管(guan)道泄漏(lou)頂壓工(gong)具及操作方(fang)法

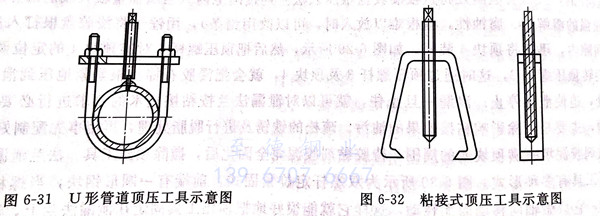

①. U形(xing)管道頂壓工具(ju)

這種頂壓工具如圖6-31所示。它主要由三大部分組成:U形螺栓、支承板、頂壓螺桿。現場操作時,首先將U形頂壓工具安裝在無泄漏的高清下載香蕉視頻app蘋果:不銹鋼管段上,調整好各部位置,然后向泄漏點方向移動,并使頂壓螺桿的軸線對準泄漏缺陷,迅速旋轉頂壓螺桿,使其前端的鋁鉚釘牢牢地壓在泄漏點上,迫使泄漏停止。泄漏一旦止住,既可處理需要粘接的金屬部位,并用事先配制好的膠黏劑膠泥把鋁鉚釘或軟性填料粘于泄漏部位上,待膠黏劑充分固化后,就可以拆除頂壓工具,鋸掉長出的鋁鉚釘,完成作業。

②. 粘接式頂(ding)壓工具

這(zhe)種頂壓(ya)工(gong)(gong)具(ju)必須先采(cai)用(yong)快速固(gu)化(hua)的(de)(de)膠黏劑將(jiang)其粘(zhan)接在泄漏缺陷上,然后消除泄漏。它(ta)的(de)(de)基本形(xing)式如(ru)圖6-32所示,由支(zhi)承架及頂壓(ya)螺桿組(zu)成。帶壓(ya)修(xiu)補作(zuo)業前,首先把泄漏周圍(wei),特別是粘(zhan)接固(gu)定(ding)(ding)頂壓(ya)工(gong)(gong)具(ju)的(de)(de)位置,按粘(zhan)接技術的(de)(de)要(yao)求認真處理(li)好,然后觀察頂壓(ya)工(gong)(gong)具(ju)的(de)(de)兩(liang)個支(zhi)腳與泄漏部(bu)位的(de)(de)吻合情況。如(ru)果兩(liang)者間(jian)隙(xi)相差太(tai)大,則應調整一下,同時使頂壓(ya)螺桿的(de)(de)軸線通(tong)過泄漏缺陷的(de)(de)中心,并在腳上做標記,這(zhe)時就可(ke)以粘(zhan)接固(gu)定(ding)(ding)頂壓(ya)工(gong)(gong)具(ju)了(le)。頂壓(ya)工(gong)(gong)具(ju)在不銹鋼管(guan)道(dao)上的(de)(de)粘(zhan)接形(xing)式有兩(liang)種,一種是軸向粘(zhan)接式,另(ling)一種是環向粘(zhan)接式。

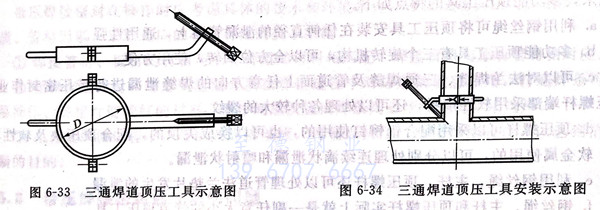

③. 三(san)通(tong)焊道專用頂(ding)壓工具(ju)

三通(tong)(tong)焊道(dao)專用頂(ding)壓工具基本結構如圖6-33所(suo)示。它由固(gu)定部(bu)(bu)分及頂(ding)壓螺(luo)桿兩部(bu)(bu)分組成(cheng)、作(zuo)(zuo)業(ye)時,根據泄(xie)(xie)漏量的(de)大小,選擇好頂(ding)壓螺(luo)桿、然后(hou)把兩半的(de)鐵箍螺(luo)栓連接固(gu)定在泄(xie)(xie)漏法蘭(lan)上、通(tong)(tong)過扳(ban)動手柄,使頂(ding)壓螺(luo)桿的(de)軸(zhou)線正好通(tong)(tong)過泄(xie)(xie)漏缺陷的(de)中心(xin),然后(hou)把連接螺(luo)栓擰禁,如圖6-34所(suo)示。對于間斷性(xing)泄(xie)(xie)漏或連續滴狀(zhuang)泄(xie)(xie)漏,應配(pei)合(he)軟性(xing)填料(liao)進(jin)行帶壓密封(feng)作(zuo)(zuo)業(ye):對于噴射狀(zhuang)泄(xie)(xie)漏,則(ze)應配(pei)合(he)鋁鉚(liu)釘(ding)進(jin)行帶壓密封(feng)作(zuo)(zuo)業(ye)。

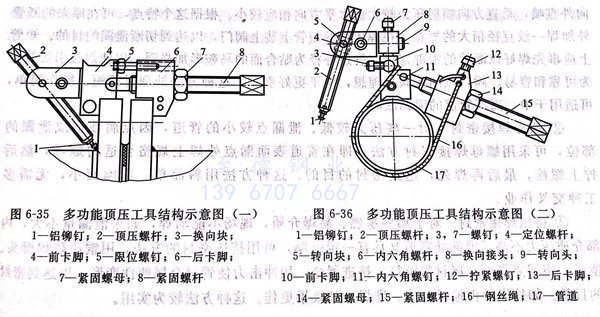

④. 多(duo)功能頂壓工具

多(duo)功(gong)能(neng)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)是(shi)(shi)(shi)根據常見泄(xie)漏(lou)部(bu)(bu)(bu)位(wei)的(de)(de)(de)(de)(de)(de)(de)(de)情(qing)況,綜合各類頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)的(de)(de)(de)(de)(de)(de)(de)(de)特(te)點而(er)設計的(de)(de)(de)(de)(de)(de)(de)(de)一(yi)種(zhong)小(xiao)巧玲瓏(long)、通(tong)(tong)(tong)用(yong)(yong)(yong)性強的(de)(de)(de)(de)(de)(de)(de)(de)帶(dai)壓(ya)(ya)修(xiu)補作業專用(yong)(yong)(yong)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)。圖(tu)(tu)6-35所(suo)(suo)示(shi)(shi)是(shi)(shi)(shi)這種(zhong)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)安(an)(an)(an)裝在(zai)(zai)(zai)不銹鋼(gang)法蘭上(shang)(shang)(shang)(shang)(shang)的(de)(de)(de)(de)(de)(de)(de)(de)情(qing)況,圖(tu)(tu)6-36所(suo)(suo)示(shi)(shi)是(shi)(shi)(shi)這種(zhong)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)安(an)(an)(an)裝在(zai)(zai)(zai)管道(dao)(dao)上(shang)(shang)(shang)(shang)(shang)的(de)(de)(de)(de)(de)(de)(de)(de)情(qing)況,從(cong)圖(tu)(tu)中(zhong)可(ke)(ke)以(yi)看出,多(duo)功(gong)能(neng)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)曲四大(da)部(bu)(bu)(bu)分(fen)(fen)(fen)組成,第(di)一(yi)部(bu)(bu)(bu)分(fen)(fen)(fen)是(shi)(shi)(shi)頂(ding)壓(ya)(ya)止(zhi)漏(lou)部(bu)(bu)(bu)分(fen)(fen)(fen),包括(kuo)鋁鉚釘(ding)1、頂(ding)壓(ya)(ya)螺(luo)(luo)(luo)(luo)桿(gan)(gan)2、定(ding)位(wei)螺(luo)(luo)(luo)(luo)桿(gan)(gan)4、轉向(xiang)塊(kuai)5、內六(liu)角(jiao)螺(luo)(luo)(luo)(luo)桿(gan)(gan)6、螺(luo)(luo)(luo)(luo)釘(ding)7、換向(xiang)接(jie)頭8、轉向(xiang)頭9.第(di)二部(bu)(bu)(bu)分(fen)(fen)(fen)是(shi)(shi)(shi)前(qian)卡(ka)腳(jiao),前(qian)卡(ka)腳(jiao)的(de)(de)(de)(de)(de)(de)(de)(de)作用(yong)(yong)(yong)是(shi)(shi)(shi),它(ta)(ta)的(de)(de)(de)(de)(de)(de)(de)(de)上(shang)(shang)(shang)(shang)(shang)端(duan)(duan)可(ke)(ke)以(yi)安(an)(an)(an)裝換向(xiang)接(jie)頭,也可(ke)(ke)以(yi)直接(jie)安(an)(an)(an)裝轉向(xiang)9,轉向(xiang)頭也可(ke)(ke)直接(jie)按要求安(an)(an)(an)裝在(zai)(zai)(zai)旁邊的(de)(de)(de)(de)(de)(de)(de)(de)孔(kong)內,并把(ba)螺(luo)(luo)(luo)(luo)釘(ding)3拆(chai)下,擰(ning)入它(ta)(ta)下端(duan)(duan)的(de)(de)(de)(de)(de)(de)(de)(de)螺(luo)(luo)(luo)(luo)紋孔(kong)內起固(gu)(gu)(gu)(gu)(gu)定(ding)作用(yong)(yong)(yong),前(qian)卡(ka)腳(jiao)也是(shi)(shi)(shi)通(tong)(tong)(tong)過(guo)(guo)鋼(gang)絲(si)(si)繩(sheng)(sheng)(sheng)及后卡(ka)腳(jiao),使(shi)(shi)整套(tao)(tao)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)固(gu)(gu)(gu)(gu)(gu)定(ding)在(zai)(zai)(zai)泄(xie)漏(lou)管道(dao)(dao)上(shang)(shang)(shang)(shang)(shang)的(de)(de)(de)(de)(de)(de)(de)(de)構件(jian)。它(ta)(ta)的(de)(de)(de)(de)(de)(de)(de)(de)上(shang)(shang)(shang)(shang)(shang)端(duan)(duan)可(ke)(ke)以(yi)攀纏鋼(gang)絲(si)(si)繩(sheng)(sheng)(sheng),也可(ke)(ke)以(yi)固(gu)(gu)(gu)(gu)(gu)定(ding)在(zai)(zai)(zai)泄(xie)漏(lou)法蘭上(shang)(shang)(shang)(shang)(shang),并通(tong)(tong)(tong)過(guo)(guo)內六(liu)角(jiao)螺(luo)(luo)(luo)(luo)釘(ding)11、緊(jin)(jin)固(gu)(gu)(gu)(gu)(gu)螺(luo)(luo)(luo)(luo)桿(gan)(gan)15使(shi)(shi)前(qian)后卡(ka)腳(jiao)連為一(yi)體(ti)。第(di)三部(bu)(bu)(bu)分(fen)(fen)(fen)是(shi)(shi)(shi)卡(ka)腳(jiao)部(bu)(bu)(bu)分(fen)(fen)(fen),它(ta)(ta)的(de)(de)(de)(de)(de)(de)(de)(de)作用(yong)(yong)(yong)也是(shi)(shi)(shi)使(shi)(shi)整套(tao)(tao)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)固(gu)(gu)(gu)(gu)(gu)定(ding)在(zai)(zai)(zai)泄(xie)握部(bu)(bu)(bu)位(wei)上(shang)(shang)(shang)(shang)(shang),它(ta)(ta)的(de)(de)(de)(de)(de)(de)(de)(de)上(shang)(shang)(shang)(shang)(shang)端(duan)(duan)有兩(liang)個(ge)7mm的(de)(de)(de)(de)(de)(de)(de)(de)通(tong)(tong)(tong)孔(kong),用(yong)(yong)(yong)于(yu)穿過(guo)(guo)鋼(gang)絲(si)(si)繩(sheng)(sheng)(sheng),并通(tong)(tong)(tong)過(guo)(guo)擰(ning)緊(jin)(jin)螺(luo)(luo)(luo)(luo)釘(ding)12使(shi)(shi)鋼(gang)絲(si)(si)繩(sheng)(sheng)(sheng)固(gu)(gu)(gu)(gu)(gu)定(ding)在(zai)(zai)(zai)前(qian)卡(ka)腳(jiao)上(shang)(shang)(shang)(shang)(shang),前(qian)卡(ka)腳(jiao)的(de)(de)(de)(de)(de)(de)(de)(de)中(zhong)部(bu)(bu)(bu)為一(yi)個(ge)17mm的(de)(de)(de)(de)(de)(de)(de)(de)圓孔(kong),緊(jin)(jin)固(gu)(gu)(gu)(gu)(gu)螺(luo)(luo)(luo)(luo)桿(gan)(gan)15從(cong)此(ci)孔(kong)穿過(guo)(guo),并可(ke)(ke)通(tong)(tong)(tong)過(guo)(guo)旋轉緊(jin)(jin)固(gu)(gu)(gu)(gu)(gu)螺(luo)(luo)(luo)(luo)母14,起到收緊(jin)(jin)鋼(gang)絲(si)(si)繩(sheng)(sheng)(sheng)的(de)(de)(de)(de)(de)(de)(de)(de)作用(yong)(yong)(yong)。同理,在(zai)(zai)(zai)處理法蘭泄(xie)漏(lou)時,多(duo)功(gong)能(neng)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)也是(shi)(shi)(shi)通(tong)(tong)(tong)過(guo)(guo)緊(jin)(jin)固(gu)(gu)(gu)(gu)(gu)螺(luo)(luo)(luo)(luo)母14使(shi)(shi)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)固(gu)(gu)(gu)(gu)(gu)定(ding)在(zai)(zai)(zai)法蘭上(shang)(shang)(shang)(shang)(shang)的(de)(de)(de)(de)(de)(de)(de)(de),緊(jin)(jin)固(gu)(gu)(gu)(gu)(gu)螺(luo)(luo)(luo)(luo)桿(gan)(gan)的(de)(de)(de)(de)(de)(de)(de)(de)規格為M16.第(di)四部(bu)(bu)(bu)分(fen)(fen)(fen)是(shi)(shi)(shi)鋼(gang)絲(si)(si)繩(sheng)(sheng)(sheng),鋼(gang)絲(si)(si)繩(sheng)(sheng)(sheng)的(de)(de)(de)(de)(de)(de)(de)(de)直徑為95mm,它(ta)(ta)的(de)(de)(de)(de)(de)(de)(de)(de)作用(yong)(yong)(yong)是(shi)(shi)(shi)通(tong)(tong)(tong)過(guo)(guo)前(qian)卡(ka)腳(jiao)和后卡(ka)腳(jiao),并通(tong)(tong)(tong)過(guo)(guo)擰(ning)緊(jin)(jin)緊(jin)(jin)固(gu)(gu)(gu)(gu)(gu)螺(luo)(luo)(luo)(luo)母14而(er)使(shi)(shi)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)固(gu)(gu)(gu)(gu)(gu)定(ding)在(zai)(zai)(zai)泄(xie)漏(lou)管道(dao)(dao)上(shang)(shang)(shang)(shang)(shang),鋼(gang)絲(si)(si)繩(sheng)(sheng)(sheng)的(de)(de)(de)(de)(de)(de)(de)(de)長度隨泄(xie)漏(lou)管道(dao)(dao)的(de)(de)(de)(de)(de)(de)(de)(de)直徑而(er)變。歸納起來,多(duo)功(gong)能(neng)頂(ding)壓(ya)(ya)工(gong)(gong)(gong)(gong)(gong)具(ju)(ju)(ju)的(de)(de)(de)(de)(de)(de)(de)(de)特(te)點如下。

a. 利用鋼絲繩可將頂壓工具(ju)安裝(zhuang)在任何直徑的泄(xie)漏管道上(shang),通(tong)用性強。

b. 多功能頂壓工具(ju)有三個旋(xuan)轉機構,可以全(quan)方(fang)位回轉,使用(yong)方(fang)便。

c. 可以(yi)對法蘭焊縫、三通焊縫及(ji)管道面上任意方向的(de)焊縫泄(xie)漏進(jin)行帶壓密封作業,頂壓螺桿端部采用軟(ruan)性填料,還可以(yi)處理各(ge)種較大的(de)裂紋。

d. 頂(ding)(ding)壓螺桿可(ke)以采用(yong)配(pei)合鋁鉚釘(ding)使用(yong)的,也(ye)可(ke)以換成尖頂(ding)(ding)的,配(pei)合頂(ding)(ding)壓塊及軟(ruan)性填料(liao)、軟(ruan)金(jin)屬(shu)使用(yong)的,可(ke)以分(fen)別處理連續滴狀(zhuang)泄漏(lou)和噴射狀(zhuang)泄漏(lou)。

e. 利(li)用鋼絲繩、主(zhu)桿、頂壓(ya)螺桿還可以處(chu)理管道(dao)法蘭墊片發(fa)生的(de)泄漏(lou)。

f. 鋼絲繩、主桿和頂壓(ya)螺桿實(shi)際上(shang)就是一(yi)副任(ren)意大小的管道(dao)頂壓(ya)工具。