漏(lou)磁場(chang)有(you)兩種拾取(qu)方法,既可以測量(liang)漏(lou)磁感應強度(du)的絕對值,也可以測量(liang)漏(lou)磁感應強度(du)的梯度(du)值。

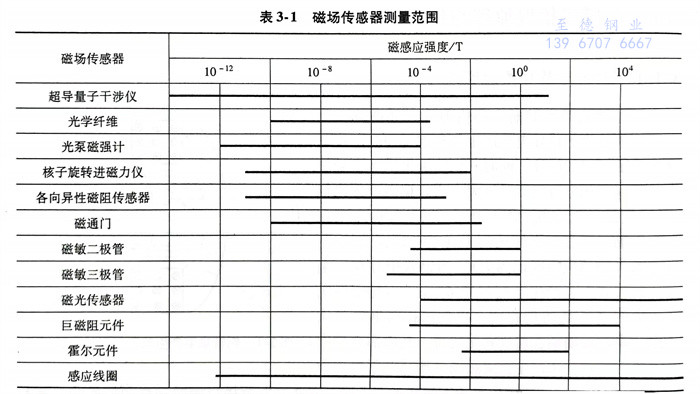

磁場(chang)傳感(gan)器(qi)的(de)作用是將磁場(chang)轉換為電信號。按原理(li)可(ke)分為體效(xiao)(xiao)(xiao)應(ying)(ying)元(yuan)件、面(mian)效(xiao)(xiao)(xiao)應(ying)(ying)元(yuan)件、P-N節注入和表(biao)面(mian)復合效(xiao)(xiao)(xiao)應(ying)(ying)元(yuan)件、量(liang)子效(xiao)(xiao)(xiao)應(ying)(ying)元(yuan)件、磁致伸縮效(xiao)(xiao)(xiao)應(ying)(ying)元(yuan)件和光纖磁傳感(gan)器(qi)等(deng)。磁場(chang)傳感(gan)器(qi)都(dou)是建立在各種效(xiao)(xiao)(xiao)應(ying)(ying)和物理(li)現象的(de)基礎之上的(de),表(biao)3-1給出了不同種類磁場(chang)傳感(gan)器(qi)的(de)測量(liang)范圍(wei),它(ta)們的(de)敏感(gan)范圍(wei)差異較大。在具體應(ying)(ying)用過程中,需要根據測量(liang)對象的(de)特點來選擇適合的(de)傳感(gan)器(qi)。

在不銹鋼(gang)管(guan)漏磁檢測中,常使用的有下列幾種磁敏傳感器。

1. 各向異性磁(ci)阻傳感器

各向異(yi)(yi)性磁(ci)(ci)阻(zu)(zu)傳感器 AMR(Anisotropic Magneto-Resistive sensors)由沉積在(zai)硅片(pian)上(shang)的(de)坡莫合金(jin)(Ni80Fe20)薄膜(mo)形成(cheng)電(dian)(dian)阻(zu)(zu),沉積時外加磁(ci)(ci)場,形成(cheng)易磁(ci)(ci)化(hua)軸(zhou)方(fang)向。易磁(ci)(ci)化(hua)軸(zhou)方(fang)向是指各向異(yi)(yi)性的(de)磁(ci)(ci)體能獲得最佳(jia)磁(ci)(ci)性能的(de)方(fang)向,也就是無(wu)外界磁(ci)(ci)干擾(rao)時磁(ci)(ci)疇整齊排(pai)列的(de)方(fang)向。鐵磁(ci)(ci)材(cai)料(liao)的(de)電(dian)(dian)阻(zu)(zu)與電(dian)(dian)流(liu)和磁(ci)(ci)化(hua)方(fang)向的(de)夾角有關,電(dian)(dian)流(liu)與磁(ci)(ci)化(hua)方(fang)向平行時電(dian)(dian)阻(zu)(zu)R最大(da),電(dian)(dian)流(liu)與磁(ci)(ci)化(hua)方(fang)向垂直(zhi)時電(dian)(dian)阻(zu)(zu)Rmin最小,電(dian)(dian)流(liu)與磁(ci)(ci)化(hua)方(fang)向成(cheng)0角時,電(dian)(dian)阻(zu)(zu)可表(biao)示為

R=Rmin+(Rmax-Rmin)cos2θ (3-2)

在磁(ci)阻(zu)傳感器中(zhong),為了消(xiao)除溫度等外(wai)界因素(su)對輸出的(de)影響(xiang),一般由4個相同的(de)磁(ci)阻(zu)元件構(gou)成惠斯通電橋。理論(lun)分析與(yu)實踐表明,采用45°偏置(zhi)磁(ci)場(chang),當(dang)沿與(yu)易(yi)磁(ci)化軸垂直的(de)方(fang)向施(shi)加外(wai)磁(ci)場(chang),且(qie)外(wai)磁(ci)場(chang)強度不太大時,電橋輸出與(yu)外(wai)加磁(ci)場(chang)強度呈線(xian)性關系。

2. 磁通門

磁(ci)(ci)(ci)通(tong)門傳感(gan)(gan)器又稱(cheng)為(wei)磁(ci)(ci)(ci)飽和式(shi)磁(ci)(ci)(ci)敏傳感(gan)(gan)器,它是利用某些高(gao)磁(ci)(ci)(ci)導率(lv)的軟磁(ci)(ci)(ci)性材料(如坡莫合金)做(zuo)磁(ci)(ci)(ci)心,以其在交直流磁(ci)(ci)(ci)場作用下的磁(ci)(ci)(ci)飽和特(te)性以及法拉第電(dian)磁(ci)(ci)(ci)感(gan)(gan)應原(yuan)理研制的磁(ci)(ci)(ci)場測量裝置。

這種磁(ci)(ci)敏傳(chuan)感器的(de)最(zui)大特(te)點是適合(he)(he)測量零磁(ci)(ci)場附近的(de)弱磁(ci)(ci)場。傳(chuan)感器體積小,重量輕,功(gong)耗低,不受磁(ci)(ci)場梯度(du)影響(xiang),測量的(de)靈敏度(du)可(ke)達(da)0.01nT,并且可(ke)以和磁(ci)(ci)秤混合(he)(he)使(shi)用(yong)。該裝置已普(pu)遍應(ying)用(yong)于(yu)航空(kong)、地(di)面、測井等(deng)方面的(de)磁(ci)(ci)法勘探(tan)工(gong)作中。在軍事上(shang),也可(ke)用(yong)于(yu)尋找地(di)下武器(炮彈、地(di)雷等(deng))和反潛。還可(ke)用(yong)于(yu)預(yu)報天然地(di)震及空(kong)間磁(ci)(ci)測等(deng)。

3. 巨(ju)磁阻(zu)元件

物質在(zai)一(yi)定(ding)磁場作用下(xia)電(dian)阻(zu)發生(sheng)改變的(de)(de)(de)(de)現象(xiang),稱(cheng)為磁阻(zu)效(xiao)應。磁性金屬(shu)和合金材(cai)(cai)料一(yi)般(ban)都有這(zhe)(zhe)種(zhong)現象(xiang)。一(yi)般(ban)情況(kuang)下(xia),物質的(de)(de)(de)(de)電(dian)阻(zu)率(lv)在(zai)磁場中(zhong)僅發生(sheng)微小(xiao)的(de)(de)(de)(de)變化,但在(zai)某種(zhong)條件下(xia),電(dian)阻(zu)變化的(de)(de)(de)(de)幅度相(xiang)當大(da),比通常情況(kuang)下(xia)高十余倍,稱(cheng)為巨磁阻(zu)效(xiao)應(GMR)。這(zhe)(zhe)種(zhong)效(xiao)應來自于載(zai)流(liu)電(dian)子的(de)(de)(de)(de)不同(tong)自旋(xuan)狀態與磁場的(de)(de)(de)(de)作用不同(tong),因而導致電(dian)阻(zu)值的(de)(de)(de)(de)變化。GMR是一(yi)個量子力學效(xiao)應,它是在(zai)層狀的(de)(de)(de)(de)磁性薄膜結(jie)構中(zhong)觀(guan)察到的(de)(de)(de)(de),這(zhe)(zhe)種(zhong)結(jie)構由鐵磁材(cai)(cai)料和非磁材(cai)(cai)料薄層交(jiao)替疊合而成(cheng)。當鐵磁層的(de)(de)(de)(de)磁矩(ju)相(xiang)互平(ping)行(xing)時,載(zai)流(liu)子與自旋(xuan)有關(guan)的(de)(de)(de)(de)散射最(zui)小(xiao),材(cai)(cai)料有最(zui)小(xiao)的(de)(de)(de)(de)電(dian)阻(zu)。當鐵磁層的(de)(de)(de)(de)磁矩(ju)為反向平(ping)行(xing)時,與自旋(xuan)有關(guan)的(de)(de)(de)(de)散射最(zui)強(qiang),材(cai)(cai)料的(de)(de)(de)(de)電(dian)阻(zu)最(zui)大(da)。

構(gou)成(cheng)GMR磁(ci)(ci)(ci)(ci)頭(tou)和傳(chuan)(chuan)感器(qi)的(de)(de)(de)(de)核心(xin)元(yuan)件(jian)是(shi)自(zi)(zi)旋閥(spin valve)元(yuan)件(jian)。它的(de)(de)(de)(de)基本結構(gou)是(shi)由釘扎(zha)磁(ci)(ci)(ci)(ci)性層(ceng)(ceng)(如Co)、Cu間(jian)(jian)隔層(ceng)(ceng)和自(zi)(zi)由磁(ci)(ci)(ci)(ci)性層(ceng)(ceng)(如NiFe等易(yi)磁(ci)(ci)(ci)(ci)化(hua)(hua)(hua)層(ceng)(ceng))組成(cheng)的(de)(de)(de)(de)多層(ceng)(ceng)膜。由于釘扎(zha)磁(ci)(ci)(ci)(ci)性層(ceng)(ceng)的(de)(de)(de)(de)磁(ci)(ci)(ci)(ci)矩與自(zi)(zi)由磁(ci)(ci)(ci)(ci)性層(ceng)(ceng)的(de)(de)(de)(de)磁(ci)(ci)(ci)(ci)矩之間(jian)(jian)的(de)(de)(de)(de)夾角(jiao)發生(sheng)變(bian)化(hua)(hua)(hua)會導致SV-GMR元(yuan)件(jian)的(de)(de)(de)(de)電阻值(zhi)改(gai)變(bian),進(jin)而(er)使輸出電流發生(sheng)變(bian)化(hua)(hua)(hua)。運用(yong)(yong)SV-GMR元(yuan)件(jian)的(de)(de)(de)(de)磁(ci)(ci)(ci)(ci)傳(chuan)(chuan)感器(qi),其檢(jian)測(ce)靈(ling)敏度比使用(yong)(yong)MR元(yuan)件(jian)的(de)(de)(de)(de)高幾個數量級,更(geng)容(rong)易(yi)集成(cheng)化(hua)(hua)(hua),封裝尺寸(cun)更(geng)小,可靠性更(geng)高。它不僅可以取代以前(qian)的(de)(de)(de)(de)MR傳(chuan)(chuan)感器(qi),還可以制(zhi)成(cheng)傳(chuan)(chuan)感器(qi)陣列,實現智能化(hua)(hua)(hua),用(yong)(yong)來表(biao)述(shu)通行車輛、飛機(ji)機(ji)翼、建筑(zhu)防(fang)護裝置(zhi)(zhi)或管道系統中隱蔽缺陷(xian)的(de)(de)(de)(de)特征,跟(gen)蹤地磁(ci)(ci)(ci)(ci)場的(de)(de)(de)(de)異常現象等。當前(qian),GMR傳(chuan)(chuan)感器(qi)已在液壓氣缸位置(zhi)(zhi)傳(chuan)(chuan)感、真假紙幣識別、軸承編碼(ma)、電流檢(jian)測(ce)與控制(zhi)、旋轉(zhuan)位置(zhi)(zhi)檢(jian)測(ce)、車輛通行情況檢(jian)測(ce)等領域(yu)得到應用(yong)(yong)。

4. 霍爾(er)元件

霍爾(er)元(yuan)件在(zai)漏(lou)磁檢(jian)測中(zhong)應用較(jiao)為(wei)廣泛。霍爾(er)元(yuan)件是(shi)由半(ban)導體材(cai)料制成的(de)(de)一(yi)種(zhong)晶體。當給晶體材(cai)料通以(yi)電流并置于(yu)磁場(chang)(chang)之中(zhong)時,在(zai)晶體的(de)(de)兩面就會產生電壓,電壓的(de)(de)大小與磁場(chang)(chang)強(qiang)度成正(zheng)比關系。

固體(ti)(ti)導(dao)(dao)電材料(liao)幾乎可(ke)以(yi)使電子暢(chang)通無阻(zu)地流過,就像傳統的臺球(qiu)模型演示的那樣,晶(jing)(jing)體(ti)(ti)點陣上(shang)的離(li)子不會(hui)使傳導(dao)(dao)電子發生折射。當電流由晶(jing)(jing)體(ti)(ti)的一端(duan)輸入時,電子或者相互之間發生折射,或者向著晶(jing)(jing)體(ti)(ti)的另(ling)一端(duan)折射。

根據固體(ti)物理理論(lun)可知,晶(jing)體(ti)上的(de)電壓Vh為: Vh=RhIBz/b (3-3)

式中,1為所使用的(de)電(dian)流;Bz為磁(ci)(ci)場強度(du)在(zai)垂(chui)直(zhi)于電(dian)流方(fang)向上的(de)分量;b為晶體在(zai)磁(ci)(ci)場方(fang)向上的(de)厚度(du);Rh為霍爾系數(shu)。

一般情(qing)況(kuang)下,如(ru)果晶體與磁場B之(zhi)間成一定夾角,則 B2=Beosθ。

由金屬制(zhi)(zhi)成的霍爾元(yuan)(yuan)件并不(bu)是最好的,因為金屬的霍爾系數都(dou)很低。根(gen)據霍爾元(yuan)(yuan)件工作原理(li),霍爾系數越(yue)大,霍爾電(dian)壓也(ye)就越(yue)高。因此,在制(zhi)(zhi)作霍爾元(yuan)(yuan)件時,一般選用元(yuan)(yuan)素(su)周期表中第II和第IV族元(yuan)(yuan)素(su)混合制(zhi)(zhi)作,而且其對溫度的變化也(ye)最不(bu)敏(min)感。此區域的元(yuan)(yuan)素(su),載流子(zi)一般為空位(wei)而不(bu)是電(dian)子(zi)。

5. 感應線(xian)圈

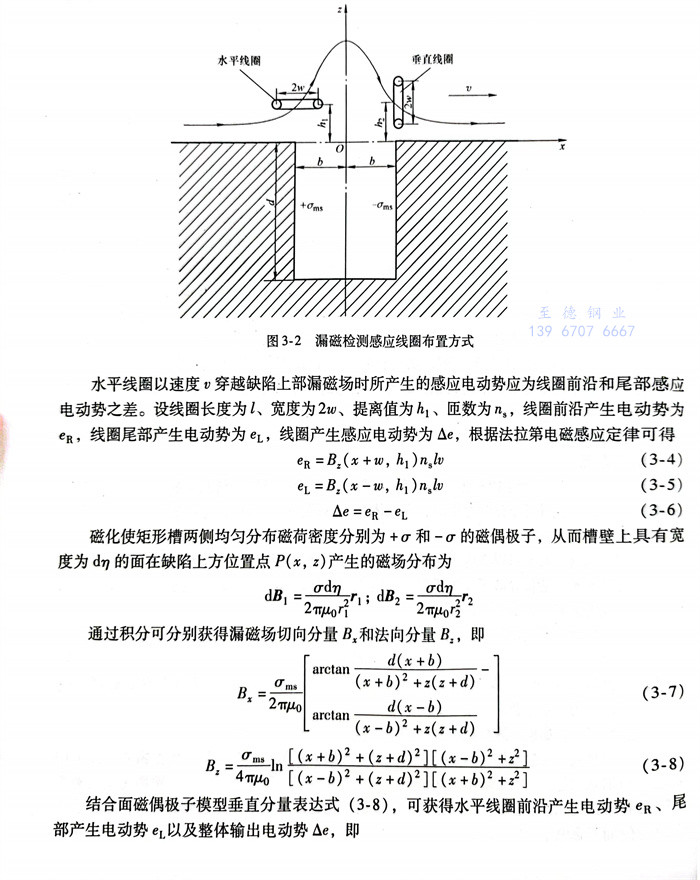

感應(ying)線(xian)圈(quan)是鋼管漏磁(ci)檢測中應(ying)用最為(wei)廣(guang)泛的磁(ci)敏傳(chuan)感器(qi),主(zhu)要有(you)水平和垂直線(xian)圈(quan)兩種布置方式(shi),如圖3-2所(suo)示(shi)。根據提離(li)效(xiao)應(ying)和法拉第電磁(ci)感應(ying)定(ding)律,為(wei)了使(shi)檢測信號與缺(que)陷(xian)特(te)征之間具有(you)良好的對應(ying)關系,感應(ying)線(xian)圈(quan)提離(li)距(ju)離(li)以及掃查速度應(ying)盡量保(bao)持恒定(ding)。

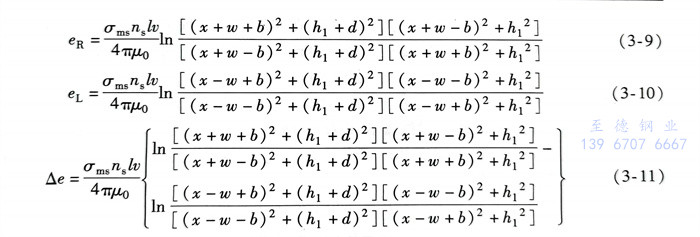

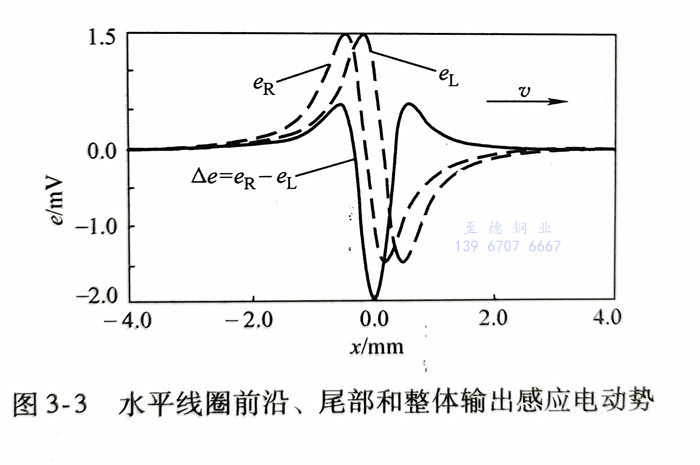

水平線(xian)圈(quan)以(yi)速(su)度v穿越缺陷上(shang)部(bu)漏磁場時所產(chan)(chan)生(sheng)的感應電(dian)動勢應為(wei)(wei)線(xian)圈(quan)前沿和尾(wei)部(bu)感應電(dian)動勢之差(cha)。設線(xian)圈(quan)長度為(wei)(wei)l、寬度為(wei)(wei)2w、提離值為(wei)(wei)h1、匝數為(wei)(wei),線(xian)圈(quan)前沿產(chan)(chan)生(sheng)電(dian)動勢為(wei)(wei)SueR,線(xian)圈(quan)尾(wei)部(bu)產(chan)(chan)生(sheng)電(dian)動勢為(wei)(wei)eL,線(xian)圈(quan)產(chan)(chan)生(sheng)感應電(dian)動勢為(wei)(wei)Δe,根據(ju)法拉(la)第電(dian)磁感應定律可得

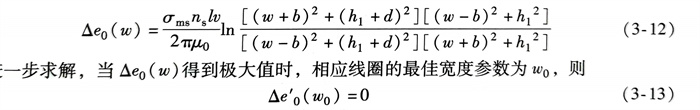

此外,從圖(tu)3-3中可以看出,水(shui)平線(xian)(xian)圈(quan)輸(shu)出感(gan)(gan)應(ying)(ying)電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)(dong)(dong)勢本質(zhi)為處于(yu)同一提離(li)高度的(de)前(qian)后導線(xian)(xian)在(zai)同一時刻的(de)電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)(dong)(dong)勢差動(dong)(dong)(dong)輸(shu)出。因此,感(gan)(gan)應(ying)(ying)線(xian)(xian)圈(quan)電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)(dong)(dong)勢輸(shu)出與(yu)線(xian)(xian)圈(quan)寬度有(you)關,并(bing)存(cun)在(zai)最(zui)佳(jia)寬度使(shi)得(de)線(xian)(xian)圈(quan)輸(shu)出最(zui)大感(gan)(gan)應(ying)(ying)電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)(dong)(dong)勢。此時,線(xian)(xian)圈(quan)運動(dong)(dong)(dong)至缺陷(xian)(xian)中間(jian)位置,并(bing)且前(qian)沿(yan)產生(sheng)正(zheng)向極值電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)(dong)(dong)勢而尾部產生(sheng)反向極值電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)(dong)(dong)勢,經過差動(dong)(dong)(dong)后可獲(huo)取最(zui)高感(gan)(gan)應(ying)(ying)電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)(dong)(dong)勢輸(shu)出。根據式(3-11),當x=0時,可獲(huo)得(de)感(gan)(gan)應(ying)(ying)線(xian)(xian)圈(quan)位于(yu)缺陷(xian)(xian)中間(jian)位置時電(dian)(dian)(dian)(dian)(dian)(dian)動(dong)(dong)(dong)勢Δeo與(yu)線(xian)(xian)圈(quan)寬度參數(shu)w的(de)關系式Δeo(w),即(ji)

同(tong)樣(yang),設置缺(que)(que)陷(xian)(xian)寬度2b為(wei)0.5mm,深度d為(wei)0.75mm以(yi)及(ji)感(gan)(gan)(gan)應(ying)線(xian)(xian)(xian)圈(quan)(quan)提離高(gao)度h1為(wei)0.25mm,根據(ju)式(3-13)可(ke)(ke)獲得最(zui)佳線(xian)(xian)(xian)圈(quan)(quan)寬度參數wo為(wei)0.3253mm。根據(ju)線(xian)(xian)(xian)圈(quan)(quan)最(zui)佳寬度參數重(zhong)新計(ji)算感(gan)(gan)(gan)應(ying)線(xian)(xian)(xian)圈(quan)(quan)前(qian)沿、尾部(bu)以(yi)及(ji)整體輸出(chu)(chu)(chu)感(gan)(gan)(gan)應(ying)電(dian)動(dong)勢(shi)曲線(xian)(xian)(xian),如圖(tu)3-4所示。從圖(tu)中可(ke)(ke)以(yi)看出(chu)(chu)(chu),當線(xian)(xian)(xian)圈(quan)(quan)移(yi)動(dong)到缺(que)(que)陷(xian)(xian)正上方(fang)時,線(xian)(xian)(xian)圈(quan)(quan)前(qian)沿感(gan)(gan)(gan)應(ying)電(dian)動(dong)勢(shi)輸出(chu)(chu)(chu)極小值而尾部(bu)輸出(chu)(chu)(chu)極大值,經(jing)差動(dong)后(hou)水平線(xian)(xian)(xian)圈(quan)(quan)輸出(chu)(chu)(chu)電(dian)動(dong)勢(shi)達到最(zui)大值。檢(jian)測線(xian)(xian)(xian)圈(quan)(quan)的(de)(de)最(zui)優(you)(you)寬度參數與(yu)缺(que)(que)陷(xian)(xian)尺寸和傳感(gan)(gan)(gan)器提離值有關。在實(shi)際生產過程中,可(ke)(ke)根據(ju)鋼管軋制過程中產生的(de)(de)自然(ran)缺(que)(que)陷(xian)(xian)特征對檢(jian)測線(xian)(xian)(xian)圈(quan)(quan)寬度進行優(you)(you)化設計(ji),以(yi)達到最(zui)佳的(de)(de)檢(jian)測效果。

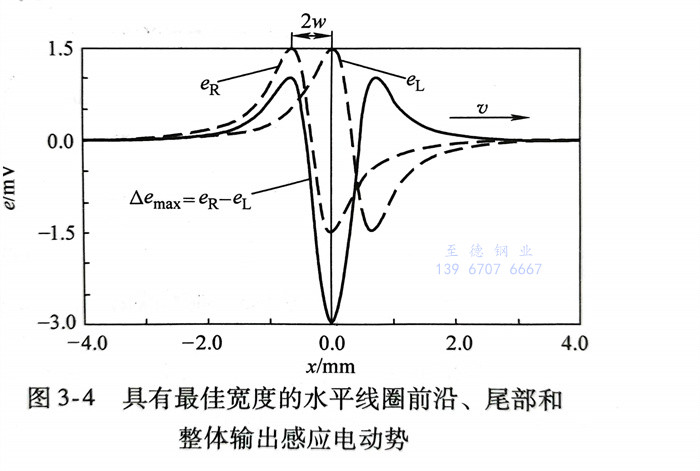

下面進一步(bu)討論垂直線圈漏(lou)磁信號輸出特性。

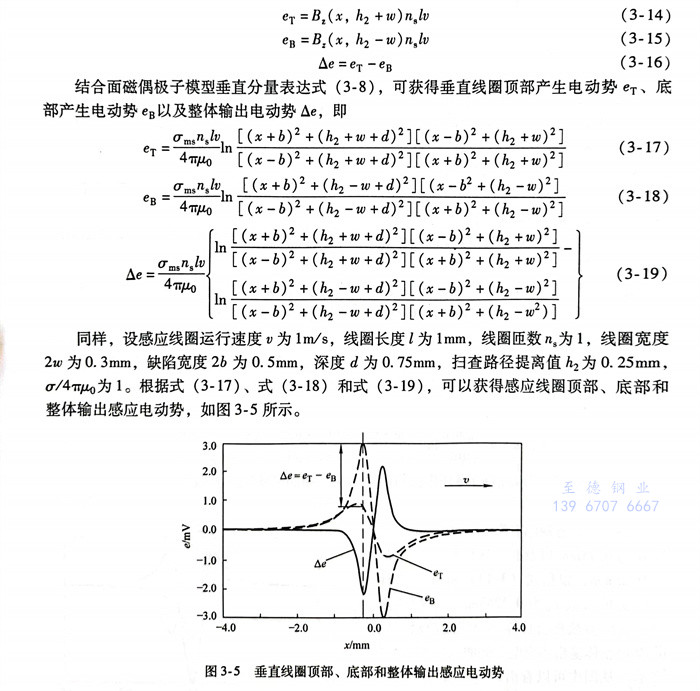

如圖3-5所示,垂直線(xian)(xian)圈以(yi)速度,穿越缺陷(xian)上部(bu)漏磁(ci)場時所產(chan)生(sheng)的電(dian)動(dong)勢(shi)(shi)輸(shu)出應(ying)為(wei)線(xian)(xian)圈頂部(bu)和底部(bu)感(gan)應(ying)電(dian)動(dong)勢(shi)(shi)之差。設線(xian)(xian)圈長度為(wei)l、匝(za)數為(wei)、寬度為(wei)2w、中心(xin)提(ti)離值為(wei),線(xian)(xian)圈頂部(bu)產(chan)生(sheng)電(dian)動(dong)勢(shi)(shi)為(wei)er,線(xian)(xian)圈底部(bu)產(chan)生(sheng)電(dian)動(dong)勢(shi)(shi)為(wei)eB,線(xian)(xian)圈產(chan)生(sheng)整體感(gan)應(ying)電(dian)動(dong)勢(shi)(shi)為(wei)Δe,根據法拉(la)第電(dian)磁(ci)感(gan)應(ying)定律可得(de)

從圖3-5中可以(yi)看出(chu),eт、eB和e三者波形相似,垂直(zhi)線(xian)圈(quan)(quan)(quan)輸出(chu)感(gan)(gan)應(ying)電(dian)動(dong)(dong)勢(shi)本質為上(shang)下兩(liang)根導線(xian)在(zai)(zai)(zai)同一時刻(ke)的(de)電(dian)動(dong)(dong)勢(shi)差動(dong)(dong)輸出(chu)。在(zai)(zai)(zai)缺陷(xian)中心位置,垂直(zhi)線(xian)圈(quan)(quan)(quan)感(gan)(gan)應(ying)電(dian)動(dong)(dong)勢(shi)輸出(chu)為零,而在(zai)(zai)(zai)缺陷(xian)兩(liang)端附近(jin)感(gan)(gan)應(ying)電(dian)動(dong)(dong)勢(shi)具有最大(da)(da)輸出(chu)值。垂直(zhi)線(xian)圈(quan)(quan)(quan)頂部(bu)(bu)和底部(bu)(bu)距離越(yue)大(da)(da),整(zheng)體感(gan)(gan)應(ying)電(dian)動(dong)(dong)勢(shi)輸出(chu)越(yue)大(da)(da)。因(yin)此,在(zai)(zai)(zai)條件允許的(de)情況下,垂直(zhi)線(xian)圈(quan)(quan)(quan)應(ying)盡量貼近(jin)鋼管表面并可通過增大(da)(da)線(xian)圈(quan)(quan)(quan)的(de)寬(kuan)度(du)來(lai)提高電(dian)動(dong)(dong)勢(shi)輸出(chu)。但(dan)在(zai)(zai)(zai)設計線(xian)圈(quan)(quan)(quan)寬(kuan)度(du)時必須(xu)考慮背(bei)景噪(zao)聲的(de)影響,垂直(zhi)線(xian)圈(quan)(quan)(quan)寬(kuan)度(du)越(yue)大(da)(da),線(xian)圈(quan)(quan)(quan)包(bao)含(han)的(de)背(bei)景噪(zao)聲越(yue)多,從而會降低缺陷(xian)漏(lou)磁信號的(de)信噪(zao)比。