墊片(gasket)是兩個物體之間的機械密封,通常以防止兩個物體之間受到壓力、腐蝕、和管路自然地熱脹冷縮泄漏。由于機械加工表面不可能完美,使用墊片即可填補不規則性。

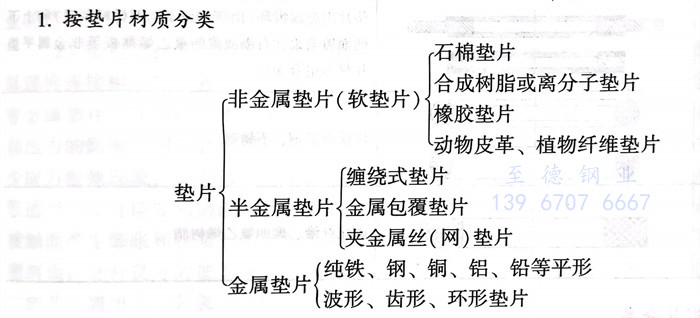

一、按墊片材質分(fen)類(lei)

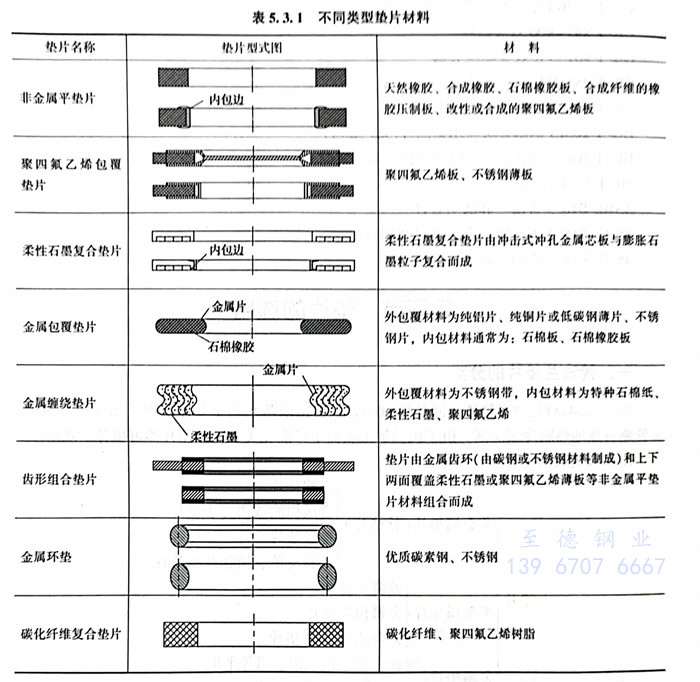

不同(tong)類型墊片(pian)材料見表5.3.1。

1. 非(fei)金(jin)屬墊(dian)(dian)(dian)片(pian)(pian)(non-metallic gasket),有石棉橡膠墊(dian)(dian)(dian)片(pian)(pian)、橡膠墊(dian)(dian)(dian)片(pian)(pian)、聚四氟乙烯墊(dian)(dian)(dian)片(pian)(pian)、合成橡膠墊(dian)(dian)(dian)片(pian)(pian)、膨脹石墨、皮(pi)革(ge)等。非(fei)金(jin)屬包(bao)覆墊(dian)(dian)(dian)片(pian)(pian)(non-metallic jacket gasket)外包(bao)一層合成樹脂等。

2. 半金屬墊(dian)(dian)片(pian)(semimetallic gasket)用金屬和(he)非金屬材(cai)料制成的墊(dian)(dian)片(pian),如纏繞式墊(dian)(dian)片(pian)、金屬包覆墊(dian)(dian)片(pian)。

①. 纏(chan)繞(rao)式墊(dian)片(spiral wound gasket)由V形(xing)(xing)或W形(xing)(xing)斷(duan)面的(de)(de)金(jin)屬(shu)帶(dai)(dai)夾非金(jin)屬(shu)帶(dai)(dai),金(jin)屬(shu)帶(dai)(dai)與非金(jin)屬(shu)帶(dai)(dai)螺旋纏(chan)繞(rao)成環(huan)(huan)形(xing)(xing)墊(dian)片。金(jin)屬(shu)帶(dai)(dai)與非金(jin)屬(shu)帶(dai)(dai)交替纏(chan)繞(rao),由于其具有較好的(de)(de)彈性,廣泛用于石化、化工(gong)、電(dian)力(li)等行業的(de)(de)法蘭密封結構中,根(gen)據具體(ti)部位(wei),可在墊(dian)片的(de)(de)內層(ceng)或外層(ceng)加(jia)上鋼環(huan)(huan)來定位(wei)或加(jia)強(qiang)。內環(huan)(huan)(inner ring)是設置在纏(chan)繞(rao)式墊(dian)片內圈的(de)(de)金(jin)屬(shu)環(huan)(huan)。外環(huan)(huan)(outerring)是設置在纏(chan)繞(rao)式墊(dian)片外圈的(de)(de)金(jin)屬(shu)環(huan)(huan)。

②. 金(jin)屬(shu)包覆。

3. 金屬墊片(pian)(metallic gasket)是(shi)用鋼、鋁、銅、鎳或蒙(meng)乃爾(er)合(he)金等金屬制(zhi)成的(de)墊片(pian)。

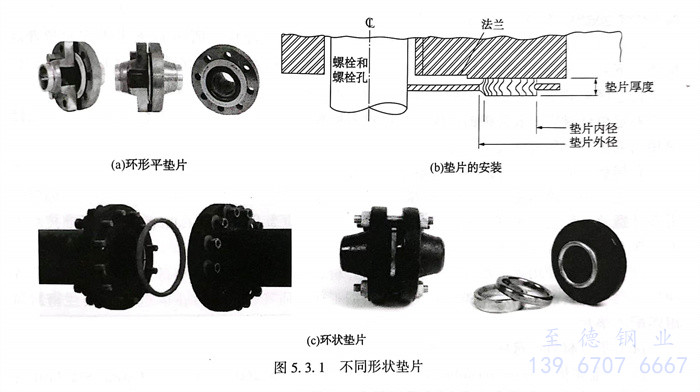

二、按墊片形(xing)狀分類

按墊(dian)片(pian)形狀分類可分為: 環(huan)狀平墊(dian)片(pian)、復合(he)型(xing)墊(dian)片(pian)、波(bo)紋型(xing)墊(dian)片(pian)、環(huan)狀墊(dian)片(pian)

不同形狀墊片如圖(tu) 5.3.1所(suo)示(shi)。