1. 聚丙烯工藝的技(ji)術發展

聚(ju)丙烯(Polypropylene,PP)是以丙烯為單體經(jing)(jing)(jing)聚(ju)合(he)反應而(er)生成(cheng)的聚(ju)合(he)樹脂(zhi)。已經(jing)(jing)(jing)成(cheng)為我國經(jing)(jing)(jing)濟建設中不可缺少的材料(liao)(liao)(liao)。具體應用(yong)在包裝材料(liao)(liao)(liao)、服裝用(yong)料(liao)(liao)(liao)、產業用(yong)料(liao)(liao)(liao)、過濾用(yong)料(liao)(liao)(liao)、衛(wei)生用(yong)料(liao)(liao)(liao)和煙用(yong)絲束等。

四十多年(nian)(nian)來(lai),聚(ju)丙(bing)烯的(de)催(cui)化(hua)劑不(bu)斷(duan)開發,不(bu)斷(duan)改(gai)性,尤其是近(jin)二十年(nian)(nian)來(lai),其技術一(yi)次又一(yi)次飛(fei)躍式的(de)進步,極(ji)大地(di)簡化(hua)了聚(ju)丙(bing)烯的(de)工藝流程,使(shi)裝置的(de)投(tou)資和生產(chan)成本降到很低的(de)水平。

聚(ju)丙烯常用(yong)工(gong)藝方法包括淤漿法工(gong)藝和本體法工(gong)藝。

①. 淤(yu)(yu)漿(jiang)法(fa)工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)(Slurry Process)又稱漿(jiang)液法(fa)或溶劑(ji)(ji)法(fa)工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi),是世界(jie)上最早(zao)用(yong)于(yu)生(sheng)(sheng)產(chan)(chan)(chan)(chan)聚(ju)(ju)(ju)丙烯(xi)(xi)的(de)(de)(de)(de)工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)技(ji)術。從1957年(nian)第一(yi)套工(gong)(gong)(gong)(gong)(gong)(gong)業(ye)化(hua)(hua)裝(zhuang)置(zhi)到現在一(yi)直是最主要(yao)的(de)(de)(de)(de)聚(ju)(ju)(ju)丙烯(xi)(xi)生(sheng)(sheng)產(chan)(chan)(chan)(chan)工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)。典(dian)型(xing)工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)主要(yao)包括意大利 Montedison 工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)、美(mei)國(guo)Hercules 工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)、日本(ben)三(san)井(jing)東壓化(hua)(hua)學工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)、美(mei)國(guo)Amoco 工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)、日本(ben)三(san)井(jing)油化(hua)(hua)工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)以及索維爾工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)等。這些(xie)(xie)工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)的(de)(de)(de)(de)開發都基于(yu)當時的(de)(de)(de)(de)第一(yi)代(dai)催化(hua)(hua)劑(ji)(ji),采用(yong)立式攪拌釜反應器,需要(yao)脫灰和(he)脫無規物(wu),因采用(yong)的(de)(de)(de)(de)溶劑(ji)(ji)不(bu)同(tong)(tong),工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)流(liu)程和(he)操作(zuo)條件有所不(bu)同(tong)(tong)。近年(nian)來,傳統的(de)(de)(de)(de)淤(yu)(yu)漿(jiang)法(fa)工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)在生(sheng)(sheng)產(chan)(chan)(chan)(chan)中的(de)(de)(de)(de)比例明顯(xian)減少(shao)(shao),保(bao)留的(de)(de)(de)(de)淤(yu)(yu)漿(jiang)產(chan)(chan)(chan)(chan)品主要(yao)用(yong)于(yu)一(yi)些(xie)(xie)高(gao)價值領域,如特(te)種BOPP薄膜、高(gao)相對分子質量吹(chui)塑膜以及高(gao)強度管(guan)材等。近年(nian)來,人們(men)對該方法(fa)進(jin)行了改進(jin),改進(jin)后的(de)(de)(de)(de)淤(yu)(yu)漿(jiang)法(fa)生(sheng)(sheng)產(chan)(chan)(chan)(chan)工(gong)(gong)(gong)(gong)(gong)(gong)藝(yi)(yi)使用(yong)高(gao)活性的(de)(de)(de)(de)第二代(dai)催化(hua)(hua)劑(ji)(ji),可刪除(chu)催化(hua)(hua)劑(ji)(ji)脫灰步驟,能(neng)減少(shao)(shao)無規聚(ju)(ju)(ju)合物(wu)的(de)(de)(de)(de)產(chan)(chan)(chan)(chan)生(sheng)(sheng),可用(yong)于(yu)生(sheng)(sheng)產(chan)(chan)(chan)(chan)均聚(ju)(ju)(ju)物(wu)、無規共聚(ju)(ju)(ju)物(wu)和(he)抗沖共聚(ju)(ju)(ju)物(wu)產(chan)(chan)(chan)(chan)品等。目(mu)前世界(jie)淤(yu)(yu)漿(jiang)法(fa)PP的(de)(de)(de)(de)生(sheng)(sheng)產(chan)(chan)(chan)(chan)能(neng)力(li)約占全球(qiu)PP總生(sheng)(sheng)產(chan)(chan)(chan)(chan)能(neng)力(li)的(de)(de)(de)(de)13%。

②. 本(ben)體(ti)(ti)(ti)法(fa)工藝(yi)的(de)(de)(de)(de)研究(jiu)開發始于20世(shi)紀60年代(dai),1964年美國Dart公(gong)(gong)司采(cai)用(yong)釜式反(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)建成了(le)世(shi)界上第一套工業化(hua)(hua)(hua)本(ben)體(ti)(ti)(ti)法(fa)聚(ju)(ju)(ju)丙烯(xi)生(sheng)產(chan)裝置。1970年以后,日本(ben)住友、Phillips、美國EI Psao等公(gong)(gong)司都實現了(le)液(ye)相(xiang)本(ben)體(ti)(ti)(ti)聚(ju)(ju)(ju)丙烯(xi)工藝(yi)的(de)(de)(de)(de)工業化(hua)(hua)(hua)生(sheng)產(chan)。與(yu)采(cai)用(yong)溶劑的(de)(de)(de)(de)漿(jiang)液(ye)法(fa)相(xiang)比,采(cai)用(yong)液(ye)相(xiang)丙烯(xi)本(ben)體(ti)(ti)(ti)法(fa)進(jin)行聚(ju)(ju)(ju)合(he)具有(you)不(bu)使用(yong)惰性(xing)(xing)溶劑,反(fan)(fan)應(ying)(ying)(ying)(ying)系統內(nei)單體(ti)(ti)(ti)濃度高,聚(ju)(ju)(ju)合(he)速率(lv)(lv)快,催化(hua)(hua)(hua)劑活性(xing)(xing)高,聚(ju)(ju)(ju)合(he)反(fan)(fan)應(ying)(ying)(ying)(ying)轉化(hua)(hua)(hua)率(lv)(lv)高,反(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)的(de)(de)(de)(de)時(shi)空生(sheng)產(chan)能(neng)(neng)力更大(da),能(neng)(neng)耗低,工藝(yi)流程簡(jian)單,設備少,生(sheng)產(chan)成本(ben)低,“三廢(fei)”量(liang)(liang)少;容(rong)易(yi)除去聚(ju)(ju)(ju)合(he)熱,并使撤熱控制簡(jian)單化(hua)(hua)(hua),可(ke)以提高單位反(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)的(de)(de)(de)(de)聚(ju)(ju)(ju)合(he)量(liang)(liang);能(neng)(neng)除去對(dui)產(chan)品性(xing)(xing)質有(you)不(bu)良影響的(de)(de)(de)(de)低分子量(liang)(liang)無規聚(ju)(ju)(ju)合(he)物(wu)和催化(hua)(hua)(hua)劑殘渣,可(ke)以得到高質量(liang)(liang)的(de)(de)(de)(de)產(chan)品等優(you)點。不(bu)足之處是反(fan)(fan)應(ying)(ying)(ying)(ying)氣體(ti)(ti)(ti)需要氣化(hua)(hua)(hua),冷凝后才(cai)能(neng)(neng)循環回反(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)。反(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)內(nei)的(de)(de)(de)(de)高壓液(ye)態烴類物(wu)料容(rong)量(liang)(liang)大(da),有(you)潛(qian)在(zai)的(de)(de)(de)(de)危險(xian)性(xing)(xing)。此外,反(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)中乙(yi)烯(xi)的(de)(de)(de)(de)濃度不(bu)能(neng)(neng)太(tai)高,否則在(zai)反(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)中形成一個單獨(du)的(de)(de)(de)(de)氣相(xiang),使得反(fan)(fan)應(ying)(ying)(ying)(ying)器(qi)難(nan)以操(cao)作,因而所得共聚(ju)(ju)(ju)產(chan)品中的(de)(de)(de)(de)乙(yi)烯(xi)含量(liang)(liang)不(bu)會太(tai)高。

本(ben)體(ti)法不(bu)同(tong)工藝(yi)路線的(de)區別主要是(shi)反應(ying)(ying)(ying)器的(de)不(bu)同(tong)。反應(ying)(ying)(ying)器可分為(wei)釜(fu)(fu)式(shi)反應(ying)(ying)(ying)器和環(huan)(huan)管反應(ying)(ying)(ying)器兩大(da)類。釜(fu)(fu)式(shi)反應(ying)(ying)(ying)器是(shi)利(li)用(yong)(yong)液體(ti)蒸發的(de)潛(qian)熱(re)來除去反應(ying)(ying)(ying)熱(re),蒸發的(de)大(da)部(bu)分氣(qi)(qi)體(ti)經循環(huan)(huan)冷(leng)凝(ning)后(hou)返回到(dao)反應(ying)(ying)(ying)器,未(wei)冷(leng)凝(ning)的(de)氣(qi)(qi)體(ti)經壓縮機升壓后(hou)循環(huan)(huan)回反應(ying)(ying)(ying)器。而環(huan)(huan)管反應(ying)(ying)(ying)器則是(shi)利(li)用(yong)(yong)軸流泵(beng)使漿液高速(su)循環(huan)(huan),通過夾套冷(leng)卻撤熱(re),由于傳熱(re)面積(ji)大(da),撤熱(re)效果(guo)好,因(yin)此其單位反應(ying)(ying)(ying)器體(ti)積(ji)產率高,能耗低。

本體法生(sheng)產工(gong)(gong)藝(yi)(yi)按聚合(he)工(gong)(gong)藝(yi)(yi)流程,可以分(fen)為間(jian)歇式聚合(he)工(gong)(gong)藝(yi)(yi)和連續式聚合(he)工(gong)(gong)藝(yi)(yi)兩種。

a. 間歇式本體法工(gong)藝

間歇本體法聚丙烯聚合(he)技(ji)術是(shi)我國(guo)自行研制(zhi)開(kai)發成功的生(sheng)產(chan)技(ji)術。它(ta)具有(you)生(sheng)產(chan)工藝技(ji)術可靠,對(dui)原(yuan)料(liao)丙烯質量要(yao)求不(bu)是(shi)很高,所需催化(hua)劑國(guo)內有(you)保證(zheng),流程簡(jian)單(dan),投資省、收效(xiao)快,操作(zuo)簡(jian)單(dan),產(chan)品(pin)(pin)(pin)牌號轉換靈活、“三廢少”,適合(he)中國(guo)國(guo)情等優點,不(bu)足之處(chu)是(shi)生(sheng)產(chan)規模小,難以產(chan)生(sheng)規模效(xiao)益(yi);裝置手工操作(zuo)較(jiao)多(duo),間歇生(sheng)產(chan),自動化(hua)控制(zhi)水平低,產(chan)品(pin)(pin)(pin)質量不(bu)穩定;原(yuan)料(liao)的消耗定額較(jiao)高;產(chan)品(pin)(pin)(pin)的品(pin)(pin)(pin)種牌號少,檔次不(bu)高,用(yong)途較(jiao)窄(zhai)。目前,我國(guo)采用(yong)該法生(sheng)產(chan)的聚丙烯生(sheng)產(chan)能力約占全國(guo)總生(sheng)產(chan)能力的24%。

b. 連(lian)續式本體法工藝(yi)

該工(gong)藝(yi)(yi)(yi)主要包括美國Rexall工(gong)藝(yi)(yi)(yi)、美國Phillips工(gong)藝(yi)(yi)(yi)以及日(ri)本Sumitimo 工(gong)藝(yi)(yi)(yi)。

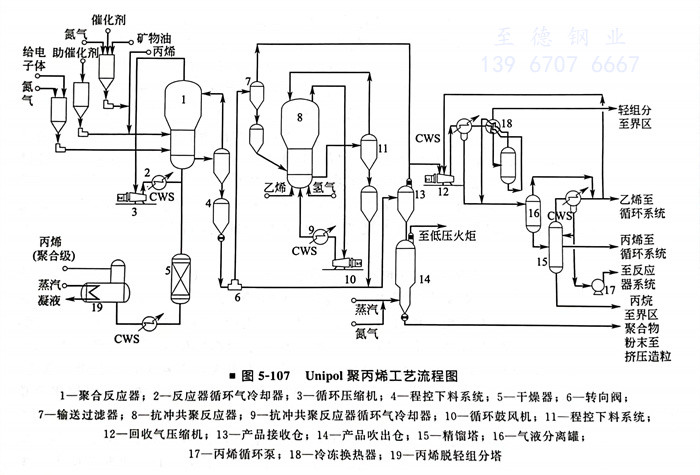

2. Dow化(hua)學公司Unipol 工藝

該工(gong)藝屬(shu)于Dow化學公司所有,Unipol聚(ju)丙烯工(gong)藝和其聚(ju)乙烯工(gong)藝類(lei)似。工(gong)藝過(guo)程主(zhu)要包(bao)括原(yuan)料(liao)精制、催(cui)化劑進料(liao)、聚(ju)合(he)反(fan)應(ying)、聚(ju)合(he)物脫氣和尾氣回收(shou)、造粒(li)、摻混和包(bao)裝碼垛等工(gong)段。

Unipol聚丙烯(xi)工藝流(liu)程,如圖(tu)5-107所示(shi)。

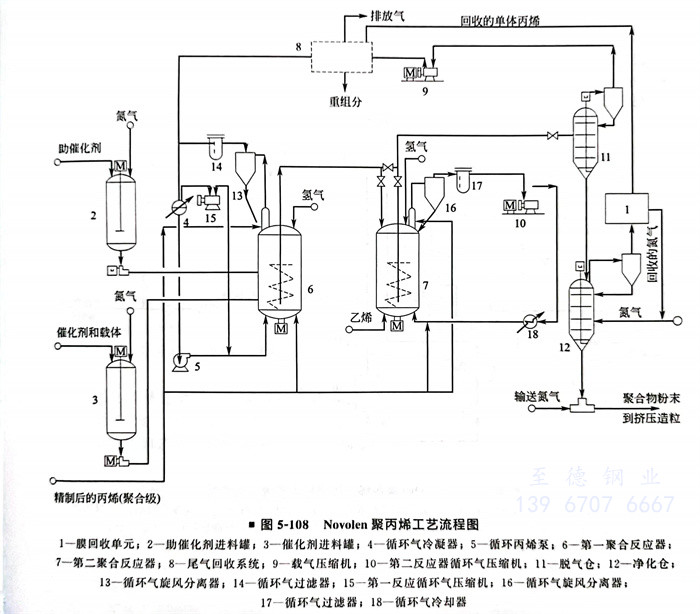

3. BASF公司(si)的Novolen 工藝(yi)

該(gai)(gai)工(gong)藝(yi)是由(you)(you) BASF公(gong)(gong)(gong)司(si)(si)開發成功的(de)。1999年(nian),該(gai)(gai)工(gong)藝(yi)擁有者 Targor 公(gong)(gong)(gong)司(si)(si)和ABB Lum-mus公(gong)(gong)(gong)司(si)(si)達(da)成協議。由(you)(you)ABB Lummus 公(gong)(gong)(gong)司(si)(si)負責(ze)在全球范圍內推廣Novolen工(gong)藝(yi)。2000年(nian)9月,被ABB公(gong)(gong)(gong)司(si)(si)和Equistar公(gong)(gong)(gong)司(si)(si)所組(zu)成的(de)合資(zi)公(gong)(gong)(gong)司(si)(si) Novolen Technology Holding(簡稱NTH)收購。2008年(nian),由(you)(you)CB&-I整體收購了 Lummus,Novolen 工(gong)藝(yi)由(you)(you)新成立的(de)CB&-ILummus負責(ze)全球轉讓。

Novolen 包括原料(liao)精制、催化劑配制、聚合反(fan)應、聚合物粉料(liao)的凈(jing)化、擠壓造粒(li)等工序(xu),如圖5-108和(he)圖5-109所示(shi)。

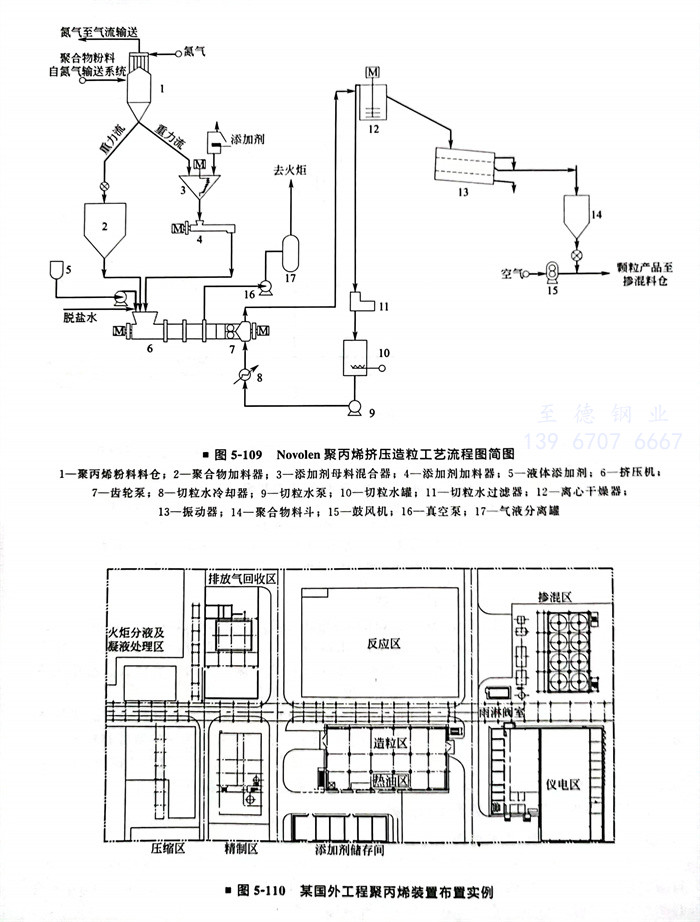

4. 某國外工程聚丙烯(xi)裝置布(bu)置實例(li)(圖5-110)