1. 限流孔板的(de)工作原理及分類(lei)

在石油(you)化工裝置(zhi)中,限流(liu)孔板(ban)用于限制流(liu)體的流(liu)量或降低流(liu)體的壓力,但通常用于工藝物料(liao)壓力降要求精度(du)不高的場合。

限流(liu)(liu)孔(kong)(kong)(kong)(kong)板(ban)(ban)(ban)(ban)為(wei)同心(xin)銳孔(kong)(kong)(kong)(kong)板(ban)(ban)(ban)(ban),流(liu)(liu)體通(tong)過(guo)(guo)孔(kong)(kong)(kong)(kong)板(ban)(ban)(ban)(ban)就會產生壓(ya)(ya)(ya)差(cha),流(liu)(liu)量隨壓(ya)(ya)(ya)差(cha)的增(zeng)大(da)而(er)(er)增(zeng)大(da)。但當壓(ya)(ya)(ya)差(cha)超過(guo)(guo)一定數值,即超過(guo)(guo)臨界壓(ya)(ya)(ya)差(cha)時,不論壓(ya)(ya)(ya)差(cha)如何增(zeng)加,流(liu)(liu)量將維持(chi)一定的數值而(er)(er)不再增(zeng)加。限流(liu)(liu)孔(kong)(kong)(kong)(kong)板(ban)(ban)(ban)(ban)就是根據(ju)這(zhe)個(ge)原理來限制流(liu)(liu)體的流(liu)(liu)量或(huo)降(jiang)低流(liu)(liu)體的壓(ya)(ya)(ya)力。限流(liu)(liu)孔(kong)(kong)(kong)(kong)板(ban)(ban)(ban)(ban)按(an)孔(kong)(kong)(kong)(kong)板(ban)(ban)(ban)(ban)上(shang)開(kai)孔(kong)(kong)(kong)(kong)數分為(wei)單孔(kong)(kong)(kong)(kong)板(ban)(ban)(ban)(ban)和(he)(he)多孔(kong)(kong)(kong)(kong)板(ban)(ban)(ban)(ban);按(an)板(ban)(ban)(ban)(ban)數可分為(wei)單板(ban)(ban)(ban)(ban)和(he)(he)多板(ban)(ban)(ban)(ban)。

2. 限(xian)流孔板的應用

①. 蒸汽(qi)(qi)(qi)吹掃(sao)管(guan)路(lu),為了(le)保(bao)證既能達到連續(xu)吹掃(sao),又保(bao)證提供最小(xiao)蒸汽(qi)(qi)(qi)流(liu)量(liang)的目的,設計中在蒸汽(qi)(qi)(qi)管(guan)線設置限流(liu)孔(kong)板,一方面限制(zhi)蒸汽(qi)(qi)(qi)流(liu)量(liang),另一方面降低了(le)蒸汽(qi)(qi)(qi)的壓力,保(bao)證了(le)管(guan)路(lu)的暢通(tong)和安(an)全(quan)運行(xing)。

②. 儲罐(guan)保壓。

③. 管線壓力平衡。

④. 在(zai)管(guan)道中閥門(men)上(shang)、下游(you)需要有較大壓降時,為減(jian)少流體對閥門(men)的沖蝕(shi),當經孔板節(jie)流不(bu)會產生氣相時,可在(zai)閥門(men)上(shang)游(you)串聯孔板。

⑤. 流體需要小(xiao)流量(liang)(liang)且連續流通的地方,如泵的沖(chong)洗管道、熱(re)備用泵的旁路(lu)管道(低流量(liang)(liang)保護(hu)管道)、分(fen)析取樣(yang)管等場所(suo)。

⑥. 需要降壓以減少噪(zao)聲或磨損的地方,如放空系統。

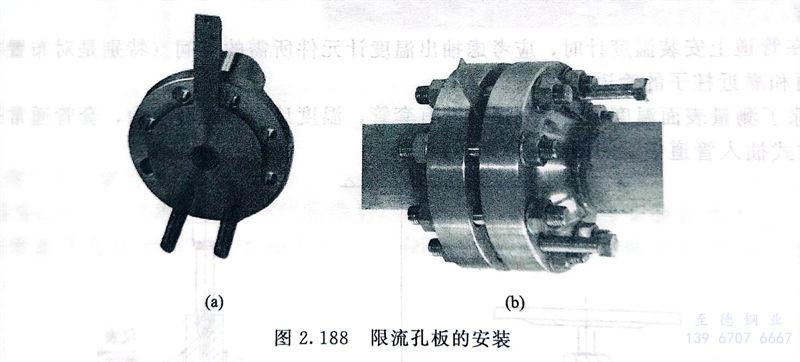

限流(liu)孔板的安裝見圖 2.188

在熱水分配站配管設計過程中,在同一個熱水分配站上的熱水伴管當量長度宜大致相等,最短熱水伴管當量長度不宜小于最長伴管當量長度的70%,否則宜設置限流孔板或截止閥以控制熱水量分配均勻。

3. 孔(kong)板流量計的布(bu)置

節流裝置一般安裝在水平管道上,如果必須在垂直段上,則液體流向必須由下向上,氣體流向必須由上向下。節流裝置應盡量安裝在維修方便的地方,要求的直管段長度內不應有焊縫、閥門(men)、管件支管和大小頭等。