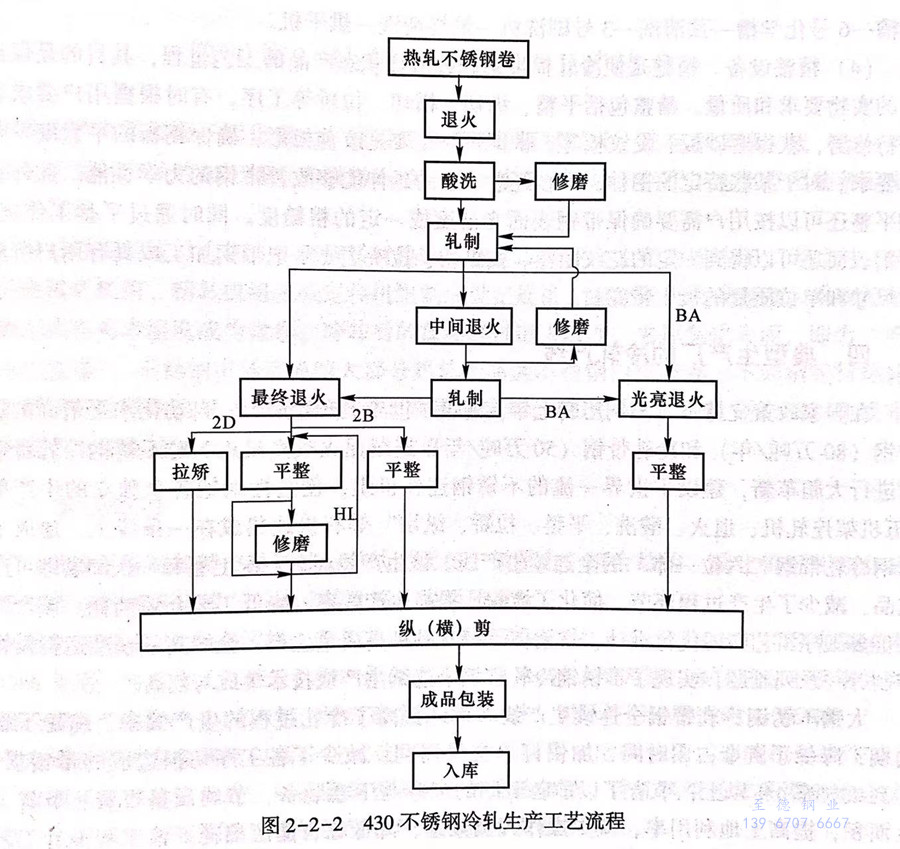

不銹鋼冷軋工藝流程為:熱軋鋼卷準備-熱卷退火酸洗一鋼卷研磨-冷軋-冷軋帶鋼退火酸洗-調質軋制一精加工研磨一精整,不銹鋼的冷軋生產工藝流程如圖2-2-2所示。

經酸洗后的原料表(biao)面若(ruo)有缺陷或(huo)成品表(biao)面要(yao)(yao)求極高時(shi),不能直接軋(ya)(ya)制,需要(yao)(yao)對原料進行修磨(mo)后才(cai)能軋(ya)(ya)制。軋(ya)(ya)制一般能在一個(ge)軋(ya)(ya)程內完成,需要(yao)(yao)兩(liang)個(ge)或(huo)兩(liang)個(ge)以(yi)上(shang)軋(ya)(ya)程時(shi),必須經過中間軟化退火(huo),就增加了軋(ya)(ya)制成本。在一個(ge)軋(ya)(ya)程內完成軋(ya)(ya)制,往往根據產品厚度(du)來選(xuan)擇原料厚度(du)。

不(bu)銹鋼冷軋(ya)工序的主體裝備非常復雜,生產全線主要包括以下設備:

1. 原料退火酸(suan)洗設(she)備

原(yuan)料退火酸(suan)洗線又稱熱(re)線,主(zhu)要包括退火和酸(suan)洗兩個功能,主(zhu)要設備組成(cheng)有(you)開卷(juan)機(ji)(ji)、焊機(ji)(ji)、活套、退火爐、冷卻段、破鱗機(ji)(ji)、拋丸機(ji)(ji)、酸(suan)洗部(bu)(bu)分、卷(juan)取機(ji)(ji)。根據不同(tong)的需(xu)要,部(bu)(bu)分原(yuan)料酸(suan)洗線還(huan)會配備軋(ya)制、平(ping)整、切邊等功能設備。

2. 軋機(ji)設備

一般(ban)而言(yan),不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)工(gong)(gong)藝中(zhong)用(yong)來(lai)生(sheng)(sheng)產(chan)(chan)(chan)不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼的(de)(de)(de)冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)主(zhu)要(yao)是(shi)(shi)二(er)十輥(gun)(gun)(gun)(gun)軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)。因(yin)(yin)其具(ju)有良好的(de)(de)(de)剛(gang)(gang)(gang)度(du)(du)(du),在生(sheng)(sheng)產(chan)(chan)(chan)不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼過(guo)程(cheng)中(zhong)有廣泛(fan)的(de)(de)(de)應用(yong)。多(duo)采(cai)(cai)用(yong)熱軋(ya)(ya)(ya)(ya)(ya)厚度(du)(du)(du)在3.0~5.5毫(hao)米的(de)(de)(de)不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼熱軋(ya)(ya)(ya)(ya)(ya)產(chan)(chan)(chan)品,經(jing)(jing)過(guo)冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)設備的(de)(de)(de)壓延加(jia)工(gong)(gong)之后(hou),生(sheng)(sheng)產(chan)(chan)(chan)成(cheng)不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)產(chan)(chan)(chan)品。當前不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)主(zhu)要(yao)生(sheng)(sheng)產(chan)(chan)(chan)工(gong)(gong)藝為(wei)三大(da)(da)類:不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼單(dan)機(ji)(ji)架冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)、不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼多(duo)機(ji)(ji)架冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)和不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼連續(xu)軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)。由于冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)是(shi)(shi)在金屬(shu)再結(jie)晶溫(wen)(wen)度(du)(du)(du)以下進(jin)行(xing),加(jia)工(gong)(gong)溫(wen)(wen)度(du)(du)(du)低(di),因(yin)(yin)此(ci)在冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)過(guo)程(cheng)中(zhong),金屬(shu)變(bian)形(xing)(xing)抗力(li)(li)增大(da)(da)、軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)壓力(li)(li)增高、同時(shi)金屬(shu)塑形(xing)(xing)降低(di)、容易產(chan)(chan)(chan)生(sheng)(sheng)脆(cui)裂,這(zhe)(zhe)種現象被稱為(wei)加(jia)工(gong)(gong)硬化(hua)(hua)現象。當鋼種一定(ding)時(shi),加(jia)工(gong)(gong)硬化(hua)(hua)程(cheng)度(du)(du)(du)與變(bian)形(xing)(xing)程(cheng)度(du)(du)(du)有關(guan),變(bian)形(xing)(xing)量加(jia)大(da)(da),加(jia)工(gong)(gong)硬化(hua)(hua)程(cheng)度(du)(du)(du)大(da)(da)。當加(jia)工(gong)(gong)硬化(hua)(hua)達(da)到一定(ding)程(cheng)度(du)(du)(du)時(shi),就不(bu)(bu)能繼續(xu)軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)。因(yin)(yin)此(ci),冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)板帶材經(jing)(jing)受一定(ding)冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)總變(bian)形(xing)(xing)后(hou),往(wang)往(wang)需要(yao)經(jing)(jing)軟化(hua)(hua)熱處(chu)理(li)(再結(jie)晶退火(huo)或固(gu)溶處(chu)理(li)等),使(shi)之恢復塑性(xing)、降低(di)抗力(li)(li),以利于繼續(xu)加(jia)工(gong)(gong)。為(wei)實(shi)現高效率、高精(jing)度(du)(du)(du)生(sheng)(sheng)產(chan)(chan)(chan),必須采(cai)(cai)用(yong)剛(gang)(gang)(gang)性(xing)大(da)(da)、小(xiao)直(zhi)徑工(gong)(gong)作輥(gun)(gun)(gun)(gun)和大(da)(da)張力(li)(li)的(de)(de)(de)多(duo)輥(gun)(gun)(gun)(gun)可(ke)逆(ni)(ni)式軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)成(cheng)卷(juan)軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi),是(shi)(shi)不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)的(de)(de)(de)顯著特點。最初,不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)多(duo)采(cai)(cai)用(yong)四輥(gun)(gun)(gun)(gun)可(ke)逆(ni)(ni)式軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)。這(zhe)(zhe)種軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)由于剛(gang)(gang)(gang)性(xing)不(bu)(bu)足(zu),軋(ya)(ya)(ya)(ya)(ya)制(zhi)(zhi)精(jing)度(du)(du)(du)不(bu)(bu)高,而且工(gong)(gong)作輥(gun)(gun)(gun)(gun)、支承輥(gun)(gun)(gun)(gun)、牌坊都很龐(pang)大(da)(da),針對這(zhe)(zhe)種情況開(kai)發出了包括(kuo)八輥(gun)(gun)(gun)(gun)、十二(er)輥(gun)(gun)(gun)(gun)、二(er)十輥(gun)(gun)(gun)(gun)等的(de)(de)(de)多(duo)輥(gun)(gun)(gun)(gun)軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)。不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)中(zhong)具(ju)有代表性(xing)的(de)(de)(de)是(shi)(shi)二(er)十輥(gun)(gun)(gun)(gun)森吉米爾軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)。目前不(bu)(bu)銹(xiu)(xiu)(xiu)(xiu)鋼的(de)(de)(de)冷(leng)(leng)(leng)(leng)(leng)(leng)軋(ya)(ya)(ya)(ya)(ya)大(da)(da)多(duo)數(shu)采(cai)(cai)用(yong)這(zhe)(zhe)種軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)。森吉米爾軋(ya)(ya)(ya)(ya)(ya)機(ji)(ji)絕大(da)(da)部分都是(shi)(shi)單(dan)機(ji)(ji)架生(sheng)(sheng)產(chan)(chan)(chan)。

3. 成(cheng)品(pin)退(tui)火酸洗設備

成品退(tui)(tui)(tui)火(huo)(huo)酸(suan)(suan)洗(xi)(xi)(xi)(xi)主要是(shi)使經(jing)冷軋(ya)后的(de)不銹(xiu)鋼通過退(tui)(tui)(tui)火(huo)(huo)軟化(hua)(hua),得(de)到要求的(de)性(xing)能,并通過酸(suan)(suan)洗(xi)(xi)(xi)(xi)消除退(tui)(tui)(tui)火(huo)(huo)過程(cheng)中生成的(de)氧化(hua)(hua)皮等(deng)(deng)雜質,進(jin)一(yi)(yi)步(bu)提高帶(dai)鋼的(de)表面(mian)(mian)質量。目前(qian)世界上成熟的(de)爐(lu)型有周期式(shi)退(tui)(tui)(tui)火(huo)(huo)爐(lu)和連續(xu)式(shi)退(tui)(tui)(tui)火(huo)(huo)爐(lu)。連續(xu)爐(lu)主要有臥(wo)式(shi)爐(lu)和立(li)式(shi)爐(lu)兩種。立(li)式(shi)爐(lu)(俗稱光亮(liang)爐(lu))主要用于生產(chan)(chan)(chan)厚度(du)為(wei)0.2~2毫米的(de)表面(mian)(mian)等(deng)(deng)級為(wei)BA的(de)鏡面(mian)(mian)板,且受現有馬弗爐(lu)長度(du)的(de)限制,其產(chan)(chan)(chan)量很低。而臥(wo)式(shi)爐(lu)的(de)產(chan)(chan)(chan)量高,且其產(chan)(chan)(chan)品規格范圍(wei)廣,生產(chan)(chan)(chan)表面(mian)(mian)等(deng)(deng)級為(wei)2B或2D的(de)普(pu)通冷軋(ya)產(chan)(chan)(chan)品。近(jin)年來(lai)酸(suan)(suan)洗(xi)(xi)(xi)(xi)工藝和設(she)備(bei)正越來(lai)越為(wei)適應環保和改善工作條件而不斷改進(jin),酸(suan)(suan)洗(xi)(xi)(xi)(xi)工藝先后經(jing)歷了化(hua)(hua)學(xue)酸(suan)(suan)洗(xi)(xi)(xi)(xi)、H2SO4電(dian)(dian)解(jie)(jie)(jie)酸(suan)(suan)洗(xi)(xi)(xi)(xi)+化(hua)(hua)學(xue)酸(suan)(suan)洗(xi)(xi)(xi)(xi)、堿液(鹽浴(yu))+電(dian)(dian)解(jie)(jie)(jie)酸(suan)(suan)洗(xi)(xi)(xi)(xi)+化(hua)(hua)學(xue)酸(suan)(suan)洗(xi)(xi)(xi)(xi)、中性(xing)鹽電(dian)(dian)解(jie)(jie)(jie)酸(suan)(suan)洗(xi)(xi)(xi)(xi)+化(hua)(hua)學(xue)酸(suan)(suan)洗(xi)(xi)(xi)(xi)等(deng)(deng)階段,工藝流(liu)程(cheng)為(wei):1號(hao)電(dian)(dian)解(jie)(jie)(jie)槽-2號(hao)電(dian)(dian)解(jie)(jie)(jie)槽-3號(hao)電(dian)(dian)解(jie)(jie)(jie)槽-1號(hao)刷洗(xi)(xi)(xi)(xi)機-4號(hao)電(dian)(dian)解(jie)(jie)(jie)槽-2號(hao)刷洗(xi)(xi)(xi)(xi)機-5號(hao)化(hua)(hua)學(xue)槽-6號(hao)化(hua)(hua)學(xue)槽一(yi)(yi)預清洗(xi)(xi)(xi)(xi)-3號(hao)刷洗(xi)(xi)(xi)(xi)機一(yi)(yi)最終清洗(xi)(xi)(xi)(xi)一(yi)(yi)烘(hong)干機。

4. 精整設備

精整(zheng)(zheng)是(shi)使冷軋板帶鋼(gang)成為交貨狀態產品(pin)的(de)(de)(de)(de)(de)工(gong)藝過程,其目的(de)(de)(de)(de)(de)是(shi)保證(zheng)產品(pin)的(de)(de)(de)(de)(de)實物要求(qiu)和質量。精整(zheng)(zheng)包括平(ping)(ping)整(zheng)(zheng)、縱切(qie)、橫切(qie)、拉(la)矯(jiao)等工(gong)序。有時(shi)根(gen)據用戶要求(qiu)還(huan)要進行修(xiu)磨,獲得磨砂(sha)板、發紋(wen)板等。帶鋼(gang)平(ping)(ping)整(zheng)(zheng)主要是(shi)改善板形,確(que)(que)保鋼(gang)板的(de)(de)(de)(de)(de)平(ping)(ping)直度符合(he)用戶要求(qiu)。對(dui)于某些特定(ding)(ding)的(de)(de)(de)(de)(de)鋼(gang)種,平(ping)(ping)整(zheng)(zheng)經過一(yi)定(ding)(ding)的(de)(de)(de)(de)(de)延伸能夠改善帶鋼(gang)的(de)(de)(de)(de)(de)力學(xue)性能。此外,帶鋼(gang)平(ping)(ping)整(zheng)(zheng)還(huan)可以按用戶需要確(que)(que)保帶鋼(gang)表面光(guang)潔度或一(yi)定(ding)(ding)的(de)(de)(de)(de)(de)粗糙度。同時(shi)通過平(ping)(ping)整(zheng)(zheng)工(gong)作輥面,帶鋼(gang)表面還(huan)可以得到一(yi)定(ding)(ding)的(de)(de)(de)(de)(de)花紋(wen)圖案(an)。橫縱切(qie)、拉(la)矯(jiao)主要是(shi)把帶鋼(gang)加工(gong)成具有用戶所(suo)需要的(de)(de)(de)(de)(de)尺寸(cun)和單位質量的(de)(de)(de)(de)(de)板、帶卷材。

至德(de)鋼業,我們根據您(nin)的實際需求,給出參考建(jian)議,為(wei)您(nin)提供高性價比的不銹鋼管道及配件。