寬幅冷彎(wan)型(xing)(xing)(xing)鋼(gang)成型(xing)(xing)(xing)機組按(an)照生(sheng)(sheng)產工(gong)藝的要(yao)(yao)求,應設(she)置有成型(xing)(xing)(xing)及成型(xing)(xing)(xing)所必需(xu)的輔助(zhu)設(she)施。一(yi)條好的成型(xing)(xing)(xing)機組,一(yi)定是能生(sheng)(sheng)產出高(gao)質量的產品,而所需(xu)能耗低,操作方便,運行安(an)全。成型(xing)(xing)(xing)機組的主要(yao)(yao)參數(shu)源(yuan)于極端情(qing)況下的工(gong)藝條件(jian)。

冷彎(wan)型(xing)(xing)(xing)(xing)(xing)鋼(gang)的(de)品種(zhong)規格多達數千種(zhong),用于加工生產冷彎(wan)型(xing)(xing)(xing)(xing)(xing)鋼(gang)的(de)冷彎(wan)成(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)機(ji)(ji)組(zu)(zu)(zu)也多種(zhong)多樣,各(ge)不相(xiang)同。有構造簡單、價格低廉的(de)成(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)機(ji)(ji)組(zu)(zu)(zu),即(ji)(ji)小(xiao)型(xing)(xing)(xing)(xing)(xing)連(lian)續成(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)機(ji)(ji)組(zu)(zu)(zu);也有技術先進、結構復雜、檢測(ce)控(kong)制(zhi)現代化的(de)造價昂貴的(de)成(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)機(ji)(ji)組(zu)(zu)(zu),即(ji)(ji)中(zhong)、大型(xing)(xing)(xing)(xing)(xing)機(ji)(ji)組(zu)(zu)(zu)。選用何種(zhong)類型(xing)(xing)(xing)(xing)(xing)機(ji)(ji)組(zu)(zu)(zu),這要依據產品的(de)厚度(du)、寬(kuan)度(du)、材質和型(xing)(xing)(xing)(xing)(xing)鋼(gang)斷面形狀(zhuang)(zhuang)的(de)復雜程度(du)(型(xing)(xing)(xing)(xing)(xing)材形狀(zhuang)(zhuang)復雜程度(du)是由彎(wan)曲(qu)的(de)個數和彎(wan)曲(qu)量(liang)的(de)大小(xiao)決定的(de))來確定。

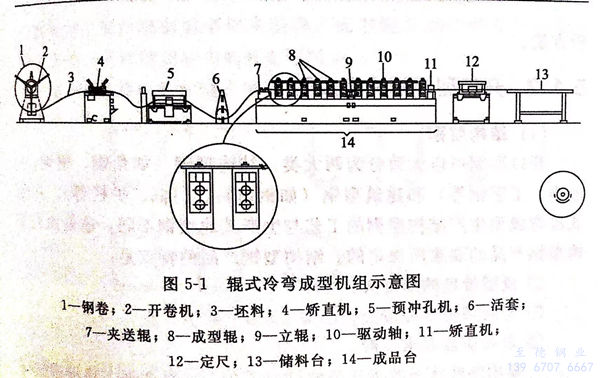

冷彎型鋼(gang)的(de)冷彎成型機組示(shi)意圖,如(ru)圖5-1所示(shi)。

1. 連續冷彎成(cheng)型機組的(de)組成(cheng)

在連(lian)續(xu)(xu)冷(leng)(leng)彎(wan)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)機(ji)(ji)組(zu)中,帶(dai)(dai)(dai)鋼(gang)需要(yao)連(lian)續(xu)(xu)不(bu)斷(duan)的(de)送(song)進(jin)(jin),以保證(zheng)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)輥及成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)機(ji)(ji)組(zu)連(lian)續(xu)(xu)不(bu)斷(duan)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing),這也是(shi)(shi)保證(zheng)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)過程的(de)穩定及成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)質量的(de)需要(yao)。為了保證(zheng)帶(dai)(dai)(dai)鋼(gang)連(lian)續(xu)(xu)送(song)進(jin)(jin),必須(xu)在成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)段(duan)前設(she)置(zhi)有上卷(juan)、開卷(juan)、對中、矯直(zhi)、帶(dai)(dai)(dai)鋼(gang)頭(tou)尾剪(jian)切(qie)等(deng)(deng)裝(zhuang)置(zhi)和(he)設(she)施;成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)段(duan)主要(yao)有成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)機(ji)(ji)和(he)對冷(leng)(leng)彎(wan)成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)后的(de)型(xing)(xing)(xing)(xing)(xing)(xing)材進(jin)(jin)行(xing)精(jing)整(矯直(zhi)、矯平)的(de)裝(zhuang)置(zhi);成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)段(duan)后有剪(jian)機(ji)(ji)、輥道平臺等(deng)(deng),主要(yao)是(shi)(shi)將已經成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)的(de)型(xing)(xing)(xing)(xing)(xing)(xing)材進(jin)(jin)行(xing)定尺剪(jian)切(qie),并完成(cheng)(cheng)(cheng)(cheng)型(xing)(xing)(xing)(xing)(xing)(xing)材的(de)定尺、垛(duo)放和(he)包裝(zhuang)等(deng)(deng)工序(xu)。

2. 小型連續(xu)冷彎成型機組

小(xiao)型連續(xu)冷彎(wan)成型機組適用于厚度較薄(bo)、幅面較窄的帶鋼成型,一般采用吊車上卷(juan)、手(shou)工開(kai)卷(juan)、手(shou)工對(dui)中和喂料等(deng),就不需(xu)要設置上卷(juan)小(xiao)車、開(kai)卷(juan)機、對(dui)中立(li)輥(gun)和矯直機等(deng)。

薄(bo)板(ban)窄帶冷彎成型的(de)變形力較小(xiao),因(yin)而大(da)多采用結(jie)構簡(jian)單、造價低(di)廉(lian)的(de)板(ban)式(shi)結(jie)構機架、鏈條鏈輪(lun)傳(chuan)動方式(shi)。為了加強兩側墻(qiang)板(ban)式(shi)機架的(de)剛性(xing),在兩板(ban)式(shi)成型機架之間上部用拉桿連接。

3. 中、大型(xing)連續冷彎成(cheng)型(xing)機組

中、大型(xing)(xing)連(lian)續冷彎成型(xing)(xing)機(ji)組(zu),適用于(yu)寬(kuan)幅、較厚的帶鋼成型(xing)(xing),由于(yu)帶鋼幅寬(kuan)、板厚,手工操作就不大可能了(le)。成型(xing)(xing)段(duan)前(qian),應包括有(you)上卷(juan)小車、開卷(juan)機(ji)(配有(you)液(ye)壓(ya)驅動的脹縮卷(juan)筒(tong))、對中立輥(gun)、帶鋼矯(jiao)直(zhi)機(ji)、液(ye)壓(ya)或機(ji)械帶鋼橫切剪切機(ji)等。成型(xing)(xing)段(duan)包括有(you)成型(xing)(xing)機(ji)和(he)(he)矯(jiao)平(ping)裝置等。成型(xing)(xing)段(duan)后面包括有(you)定尺(chi)、剪切裝置和(he)(he)輥(gun)道(dao)平(ping)臺等。

對(dui)成型機(ji)組的一般要求(qiu):

①. 設計合(he)理(li),生產(chan)的產(chan)品能滿(man)足(zu)標準要求;

②. 成型輥的安(an)裝、更換和(he)調整要(yao)方便快捷、時間(jian)短;

③. 結構緊湊,剛性(xing)好(hao),精度高;

④. 自動化程度高;

⑤. 成型速度在(zai)一定(ding)范(fan)圍內可調(diao);

⑥. 性能可(ke)靠,使用壽命長,主要元器(qi)件(電器(qi)、液壓)可(ke)靠且要有動作(zuo)互鎖功能,以防止誤操作(zuo)。