鑄造是將金屬熔煉成符合一定要求的液體并澆入鑄型內,經冷卻凝固、清整處理后得到有預定形狀、尺寸和性能的鑄件的工藝過程。

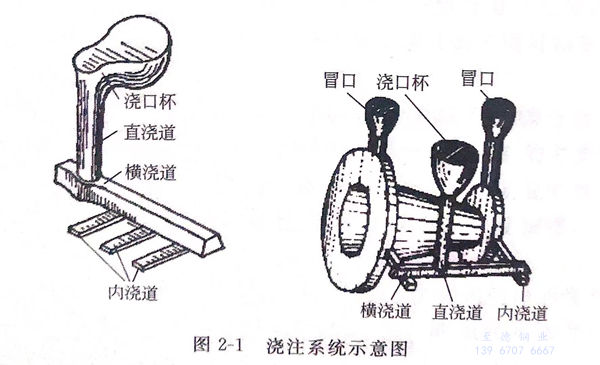

鑄(zhu)件的(de)(de)加工鑄(zhu)造(zao)(zao)(zao)(zao)(zao)可以說有許多種(zhong)工藝方法,現在(zai)(zai)使用較為(wei)廣泛的(de)(de)主要有砂型(xing)(xing)(xing)鑄(zhu)造(zao)(zao)(zao)(zao)(zao)、殼(ke)型(xing)(xing)(xing)鑄(zhu)造(zao)(zao)(zao)(zao)(zao)、精密鑄(zhu)造(zao)(zao)(zao)(zao)(zao)及陶瓷型(xing)(xing)(xing)鑄(zhu)造(zao)(zao)(zao)(zao)(zao)。所有這些鑄(zhu)造(zao)(zao)(zao)(zao)(zao)工藝的(de)(de)共同點是(shi)(shi),鑄(zhu)型(xing)(xing)(xing)都設計有澆(jiao)(jiao)注系統,即熔融(rong)金屬進入(ru)型(xing)(xing)(xing)腔的(de)(de)通道(dao);鑄(zhu)型(xing)(xing)(xing)都是(shi)(shi)在(zai)(zai)每次澆(jiao)(jiao)注完成(cheng)后就被(bei)破壞掉。這些鑄(zhu)造(zao)(zao)(zao)(zao)(zao)通道(dao)在(zai)(zai)砂型(xing)(xing)(xing)鑄(zhu)造(zao)(zao)(zao)(zao)(zao)中被(bei)稱為(wei)直澆(jiao)(jiao)道(dao)、橫澆(jiao)(jiao)道(dao)及內澆(jiao)(jiao)口(kou),見圖2-1。鑄(zhu)型(xing)(xing)(xing)是(shi)(shi)由型(xing)(xing)(xing)芯來形成(cheng)鑄(zhu)件的(de)(de)空(kong)腔和凹槽的(de)(de)。

金屬液澆注完畢之后,所(suo)得到的(de)鑄(zhu)件在出廠之前,還需要進(jin)(jin)行(xing)諸如清(qing)理(li)、檢驗、磨光以(yi)及在必(bi)要時進(jin)(jin)行(xing)的(de)焊補和熱處理(li)等(deng)后繼工序。

鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)種(zhong)(zhong)類(lei)很多,按(an)造(zao)(zao)(zao)(zao)(zao)型(xing)(xing)(xing)(xing)(xing)(xing)方法習慣分為:①. 普通砂(sha)(sha)(sha)(sha)型(xing)(xing)(xing)(xing)(xing)(xing)鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao),包括濕(shi)砂(sha)(sha)(sha)(sha)型(xing)(xing)(xing)(xing)(xing)(xing)、干砂(sha)(sha)(sha)(sha)型(xing)(xing)(xing)(xing)(xing)(xing)和化(hua)學硬化(hua)砂(sha)(sha)(sha)(sha)型(xing)(xing)(xing)(xing)(xing)(xing)三種(zhong)(zhong)類(lei)型(xing)(xing)(xing)(xing)(xing)(xing);②. 特種(zhong)(zhong)鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao),按(an)造(zao)(zao)(zao)(zao)(zao)型(xing)(xing)(xing)(xing)(xing)(xing)材(cai)料(liao)又可分為以天然礦產砂(sha)(sha)(sha)(sha)石為主(zhu)要造(zao)(zao)(zao)(zao)(zao)型(xing)(xing)(xing)(xing)(xing)(xing)材(cai)料(liao)的特種(zhong)(zhong)鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)(如熔模鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)、泥型(xing)(xing)(xing)(xing)(xing)(xing)鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)、鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)車(che)間(jian)殼型(xing)(xing)(xing)(xing)(xing)(xing)鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)、負壓鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)、實型(xing)(xing)(xing)(xing)(xing)(xing)鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)、陶瓷型(xing)(xing)(xing)(xing)(xing)(xing)鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)等)和以金(jin)屬(shu)為主(zhu)要鑄(zhu)(zhu)(zhu)型(xing)(xing)(xing)(xing)(xing)(xing)材(cai)料(liao)的特種(zhong)(zhong)鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)(如金(jin)屬(shu)型(xing)(xing)(xing)(xing)(xing)(xing)鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)、壓力鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)、連(lian)續鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)、低(di)壓鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)、離心鑄(zhu)(zhu)(zhu)造(zao)(zao)(zao)(zao)(zao)等)兩種(zhong)(zhong)類(lei)型(xing)(xing)(xing)(xing)(xing)(xing)。

鑄(zhu)造(zao)是比較經濟的毛坯成型方(fang)法(fa),對于形狀復雜的零件(jian)更能顯示出它(ta)的經濟性。如汽(qi)車(che)發動機的缸體(ti)和缸蓋,船舶螺(luo)旋槳以及精致(zhi)的工藝藝術品(pin)等。有些難以切削的零件(jian),如燃氣(qi)輪機的鎳基合金(jin)零件(jian)不用鑄(zhu)造(zao)方(fang)法(fa)是無法(fa)成型的。

另(ling)外(wai),鑄造(zao)(zao)的零件(jian)尺寸和重量的適應(ying)范圍很寬,金(jin)屬的種類(lei)幾(ji)乎不(bu)受限(xian)制;鑄造(zao)(zao)零件(jian)在具有一般機(ji)械性能(neng)的同時,還(huan)具有耐磨、耐腐(fu)蝕(shi)、吸震等綜合性能(neng),是其他(ta)金(jin)屬成型方法如鍛、軋、焊、沖壓(ya)等所達不(bu)到的。因此,在機(ji)器(qi)制造(zao)(zao)業(ye)中(zhong)用鑄造(zao)(zao)方法生產(chan)的毛坯零件(jian),在數(shu)量和噸位上迄(qi)今仍(reng)是最(zui)多的。